Sinter mixture granulating method

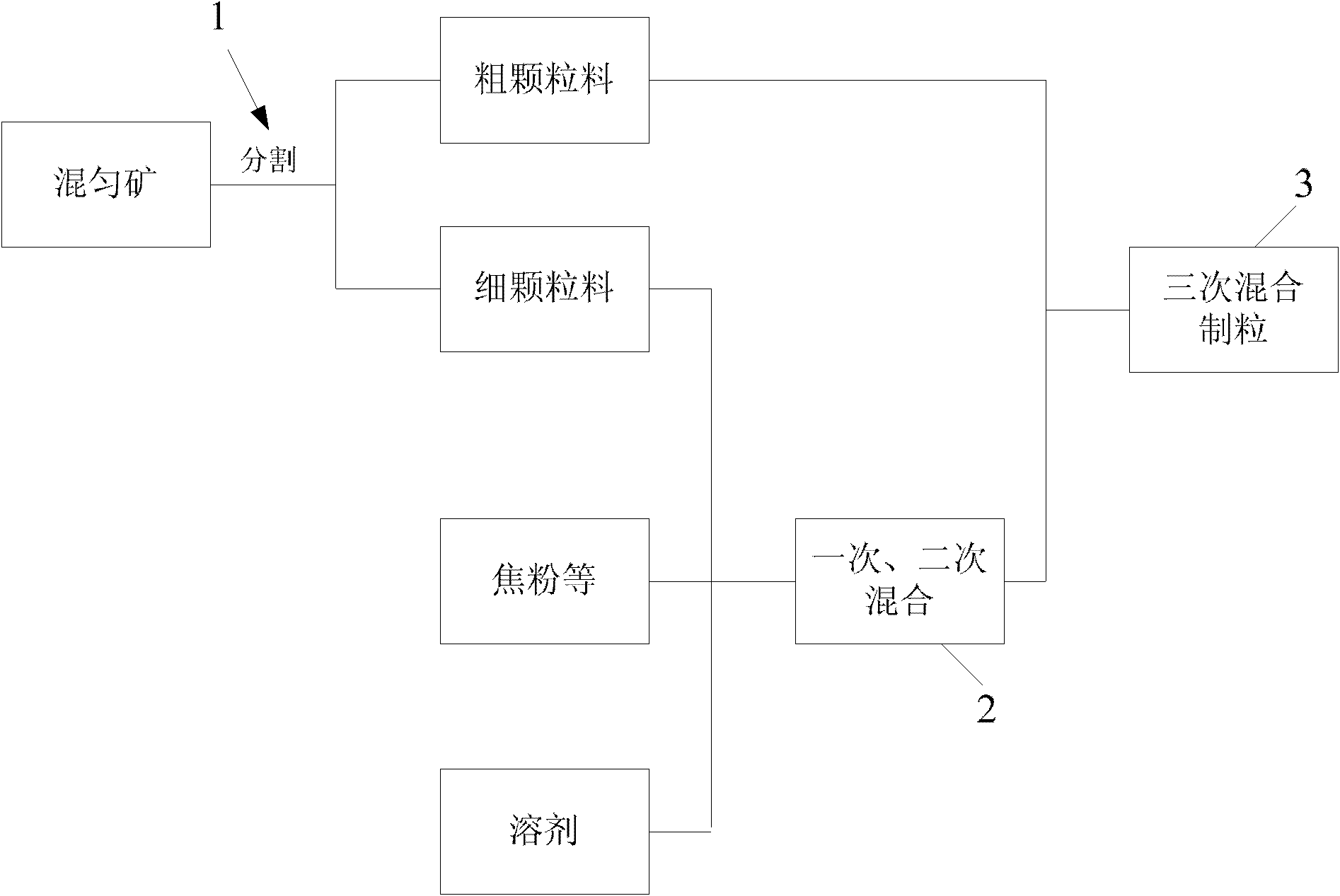

A sintering mixture and secondary mixing technology, which is applied in the field of ironmaking sintering, can solve the problems of poor granulation effect, uneven particle size, and easy rolling of the mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

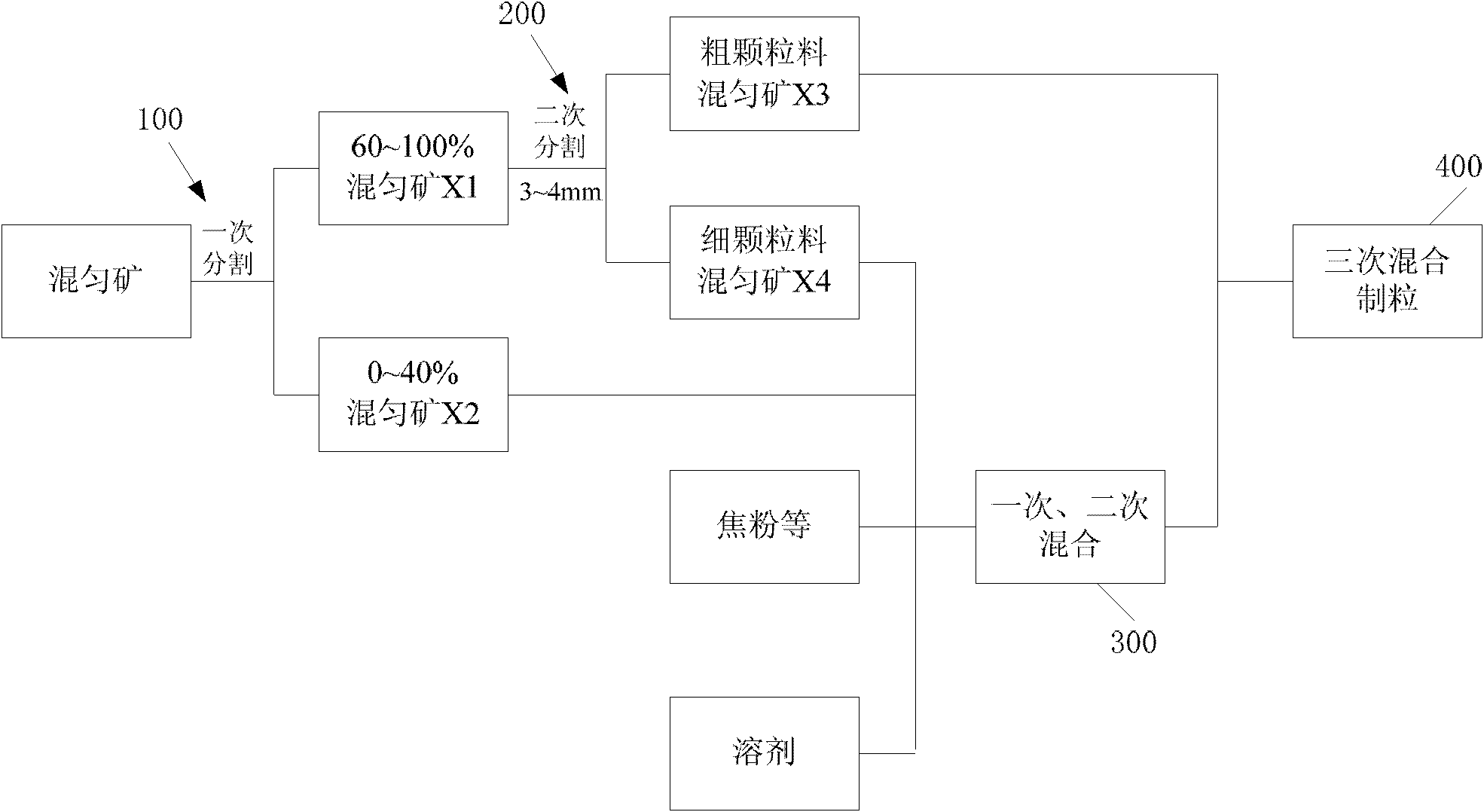

Method used

Image

Examples

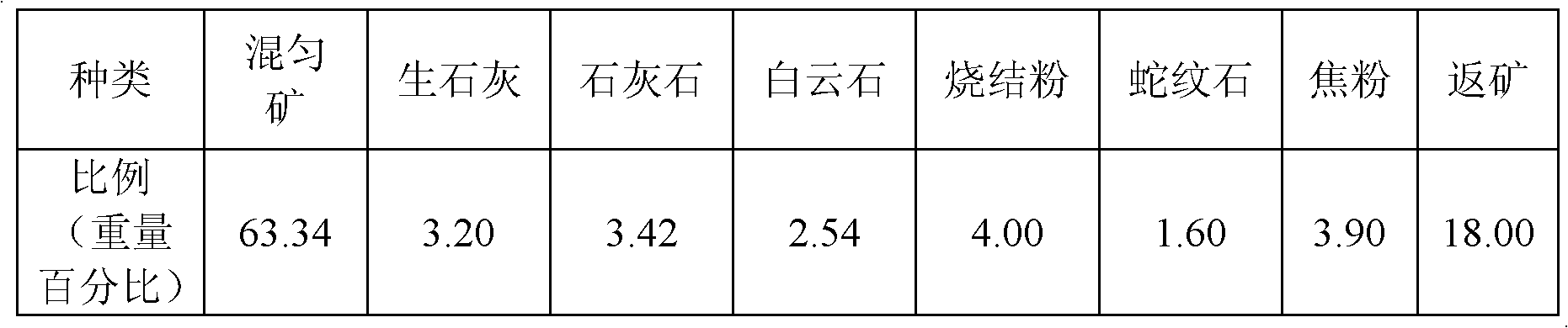

Embodiment 1

[0037] Embodiment 1 is two ratios of full division, embodiment 2 is a scheme of 70% division, and the division size is 3.15mm.

[0038] The split granulation test was carried out in a laboratory self-made cylinder mixer. The main control parameters of the mixing granulation process are:

[0039] Primary mixing: filling rate is 10-12%, cylinder speed is 27rpm, granulation time is 2min, the water content of the mixture is controlled at 6.5-7.0%, and the amount of water added accounts for 75-80% of the total, ensuring full wetting and mixing, especially Quicklime should be fully digested.

[0040] Secondary mixing: filling rate is 10-12%, cylinder speed is 27rpm, granulation time is 3min, the water content of the mixture is controlled at 7.0-7.5%, the amount of water added accounts for 20-25% of the total water amount, and the water is added in the form of atomization to improve the material Surface capillary force strengthens the granulation effect of small particles.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com