A method of using mineral material to increase the consumption and productivity of sintered iron concentrate

A technology for iron concentrate and productivity, applied in the field of sintering in the metallurgical industry, can solve problems such as narrow application range, and achieve the effects of improving the air permeability of the material layer, increasing the amount of iron concentrate, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

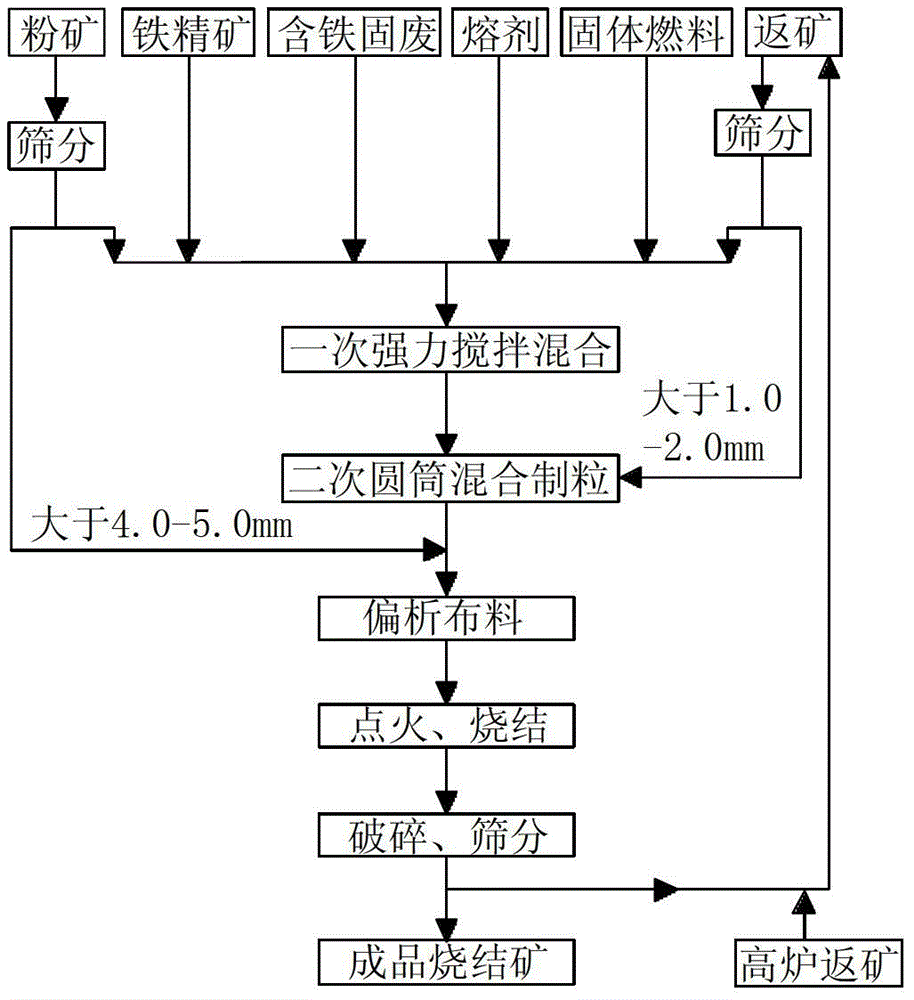

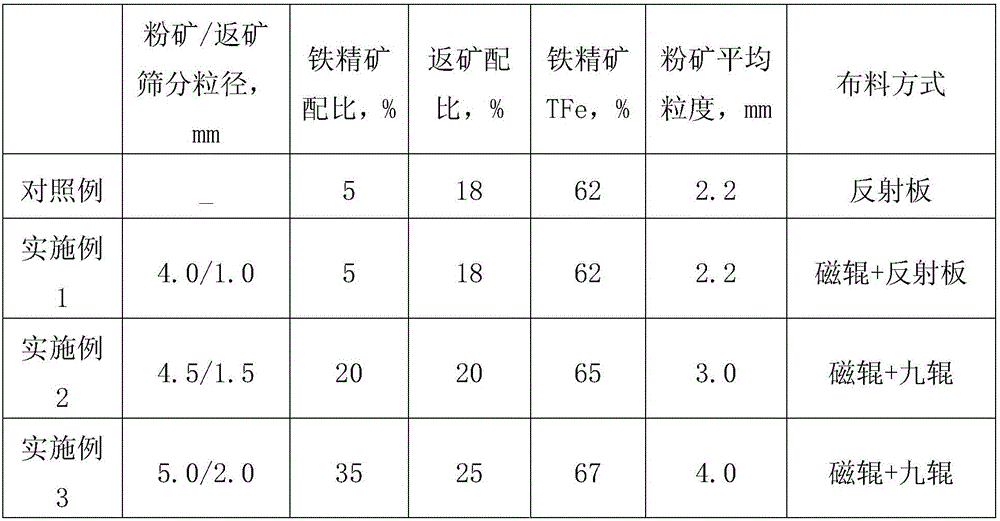

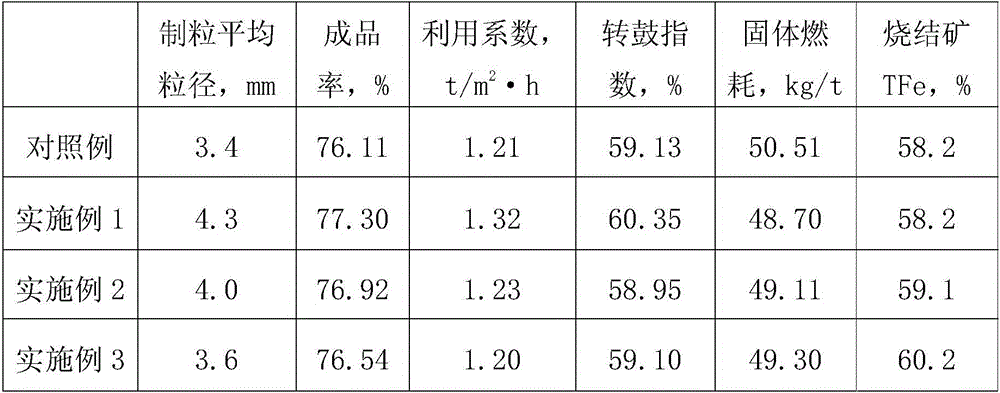

[0039] see figure 1, The method for increasing the consumption and productivity of sintered iron ore concentrate of the present invention firstly sieves the returned ore and fine ore into two parts according to the particle size of 1.0-2.0mm and 4.0-5.0mm respectively. Second, the returned ore and fine ore with a particle size of less than 1.0-2.0mm and 4.0-5.0mm, respectively, are vigorously stirred with other ingredients such as iron concentrate, iron-containing solid waste, solid fuel and flux to prepare the sintering mixture Mixing and secondary cylinder mixing and granulation. During the process of secondary cylinder mixing and granulation, return ore with a particle size greater than 1.0-2.0mm obtained by screening is added. Thirdly, during the process of transporting the mixture obtained by the secondary cylinder mixing and granulation to the mixing silo for distribution, evenly add the fine ore with a particle size greater than 4.0-5.0mm obtained by screening. Finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com