Liquid blast furnace slag granulation method and device thereof

A blast furnace slag and granulation technology, which is applied in the field of blast furnace slag utilization, can solve the problems of heavy system maintenance workload, large power consumption, and large system power consumption, and achieve the effects of reducing air consumption, increasing impact force, and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

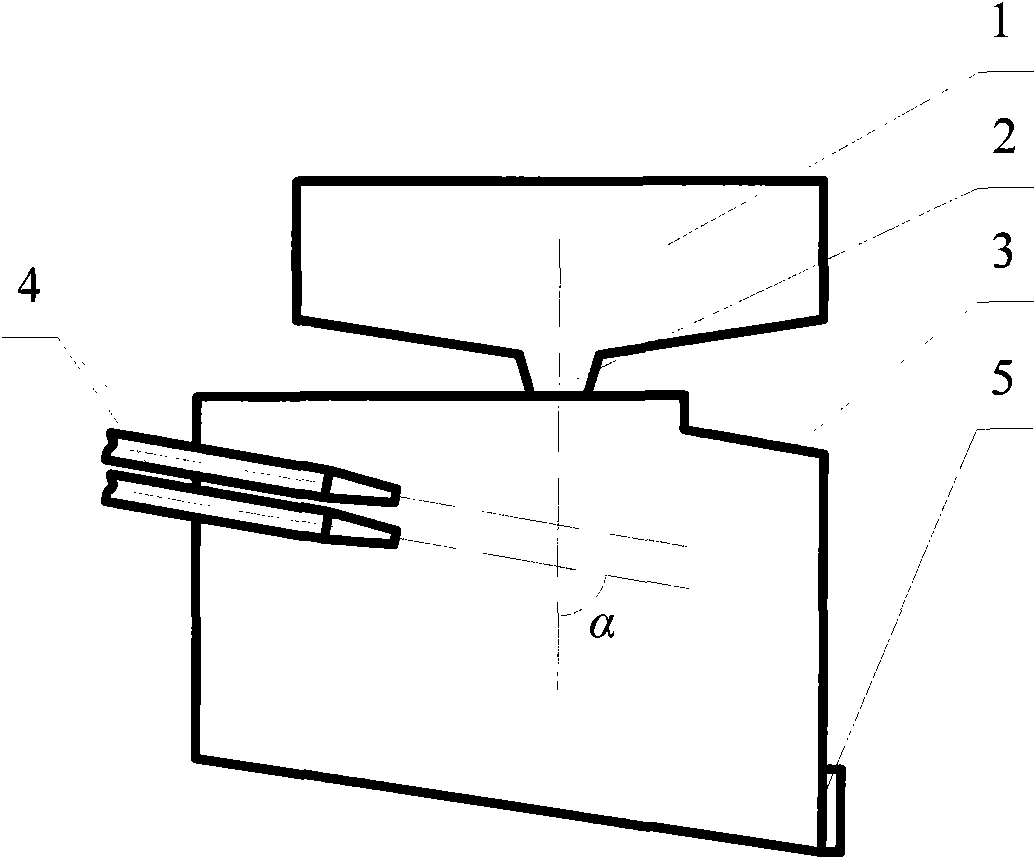

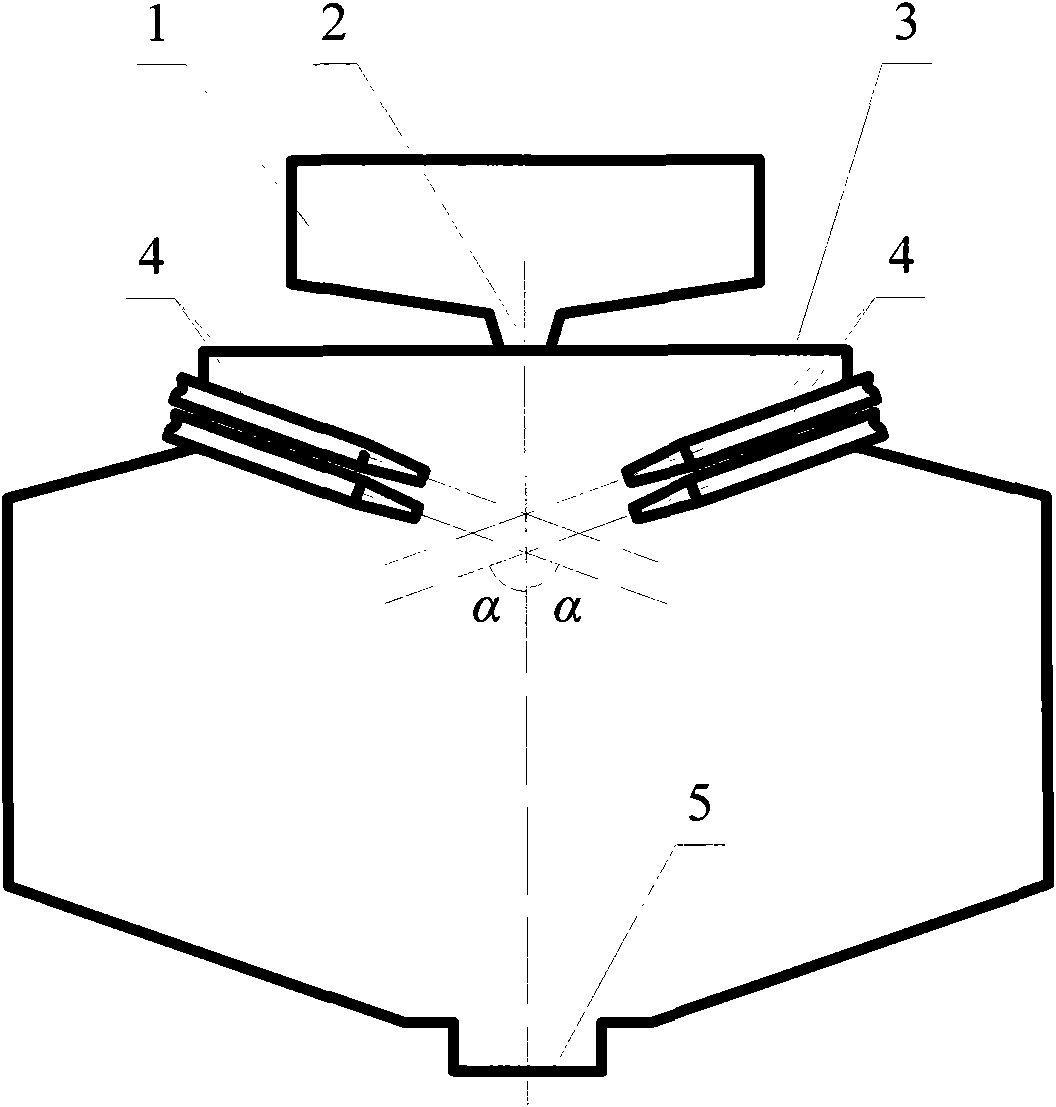

[0017] The specific structure, working principle and implementation of the device will be described in detail below in conjunction with the accompanying drawings.

[0018] The invention comprises a diversion tank 1, a slag discharge port 2, a dry granulator 3, a granulation nozzle 4 and a slag discharge port 5. The diversion tank 1 is made of refractory materials and is set on the top of the granulator. The lowest point of the diversion tank is provided with a slag outlet 2 connected with the dry granulator 3. narrow. The liquid blast furnace slag from the blast furnace slag ditch or slag tank flows into the diversion tank 1 , flows out from the slag outlet 2 at the lower part of the diversion tank 1 and falls vertically into the granulator 3 . The upper part of the granulator 3 is provided with a granulation nozzle 4, and the angle α between the outlet axis of the granulation nozzle 4 and the vertical direction is 0-90°, so that the granulation medium can obliquely cut the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com