Slag buffering system with flow control function

A flow control and buffer system technology, applied in the field of slag waste heat recovery, can solve the problems of high-quality slag waste heat resource waste, etc., and achieve the effect of continuous long-term operation, industrialization, and high safety prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

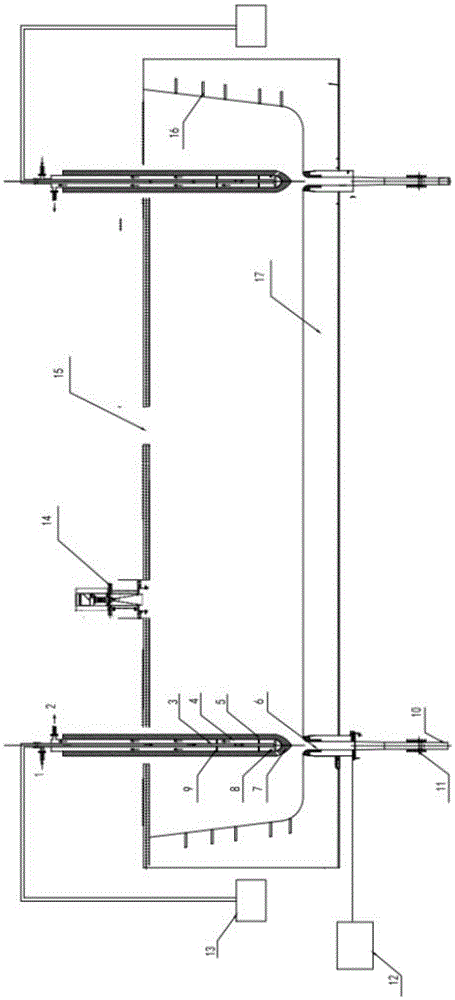

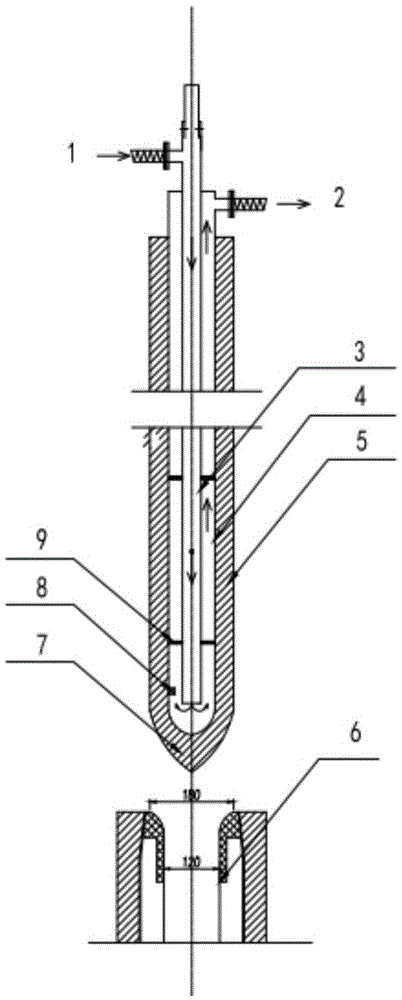

[0027] see figure 1 and figure 2 As shown, a slag buffer system with a flow control function in the present invention includes a slag cladding shell 17, a stopper, a stopper control mechanism 13, a slag drop pipe 10, a sliding nozzle and a control mechanism 12, and a liquid level monitoring device 14 and flow meter 11 .

[0028] The top of the slag ladle shell 17 has a slag inlet 15 and the bottom has one or more nozzles 6, and the slag ladle shell 17 is made of high temperature resistant material. The molten slag flows in from the slag inlet 15 above the slag ladle, and is temporarily stored in the slag ladle, and the molten slag flows from the slag drop pipe 10 at the bottom of the slag ladle shell 17 to the granulation system below.

[0029] A flow meter is installed on the outer wall of the slag falling pipe 10 to detect the slag flow in the pipe and feed back the detection signal to the stopper rod control mechanism 13 . When the flow rate is too large, the stopper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com