A control device for controlling the flow rate of liquid slag

A control device, a technology of liquid slag, which is applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of short wear life of stoppers, and achieve the effect of improving service life, realizing industrialization, and avoiding erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

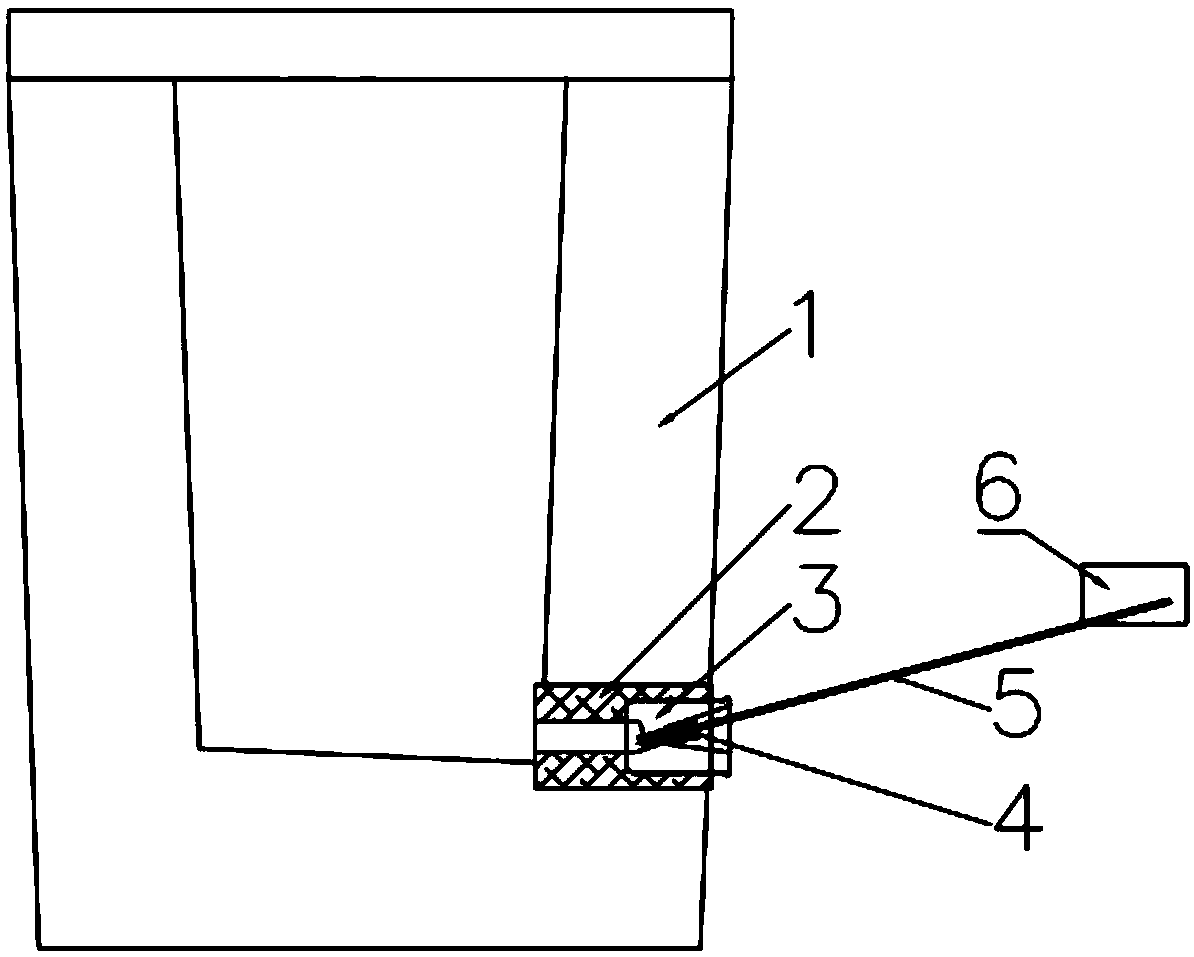

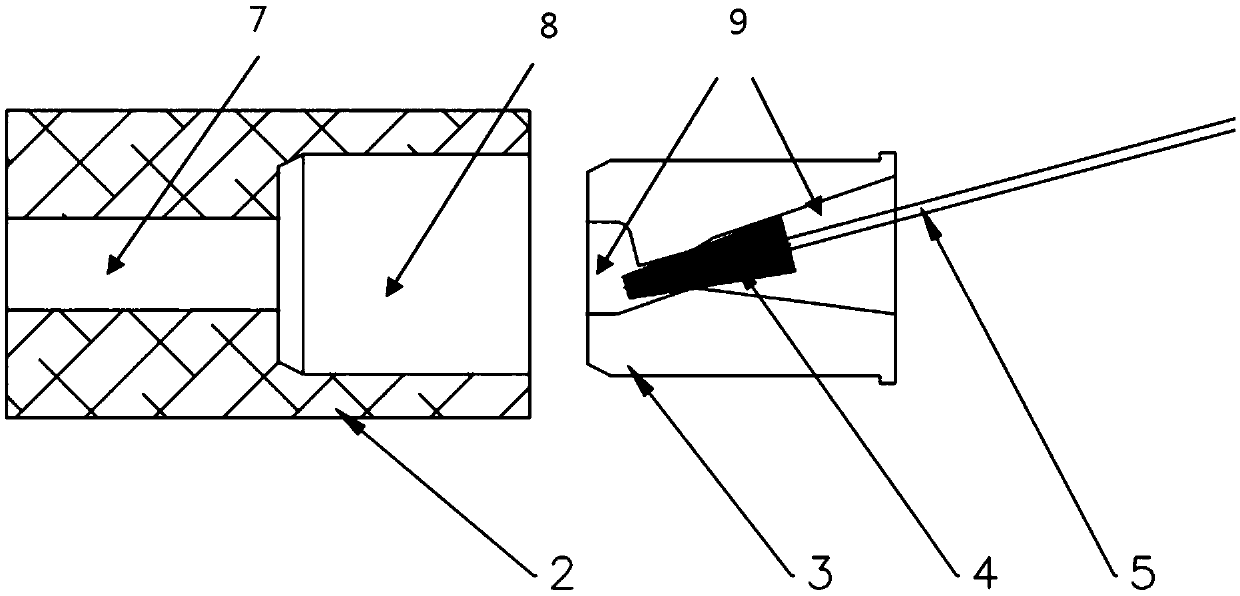

[0024] see figure 1 and figure 2 As shown, the present invention is a control device for controlling the flow rate of liquid slag, which includes a slag ladle shell 1, a seat brick 2, a sizing nozzle 3 and a stopper rod.

[0025] There is a slag inlet at the top of the slag ladle shell 1 and one or more slag outlets at the bottom. The slag ladle shell 1 is made of high temperature refractory material and steel shell. The slag outlet is provided with a block 2 embedded in the shell 1 of the slag bag, and the block 2 is provided with a flow channel 7 and a sizing nozzle accommodation chamber 8 connected to each other, and the sizing nozzle 3 is installed in the sizing nozzle accommodating chamber 8 within.

[0026] One end of the flow passage 7 of the block block is connected to the inner cavity of the slag ladle shell 1 for accommodating molten slag, and the other end is connected to the entrance of the inner flow passage 9 of the sizing nozzle 3 .

[0027] The molten slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com