Method for processing laterite-nickel ore

A technology of lateritic nickel ore and silicon-magnesium-nickel ore, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption and increased acid consumption in pyrotechnics, and achieve the effect of high recovery rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

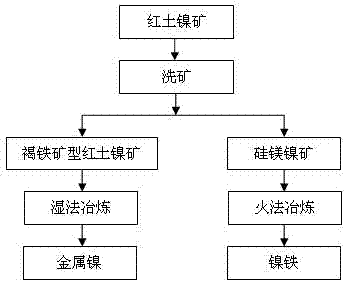

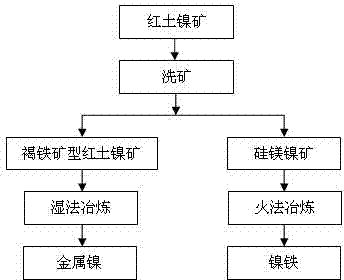

Image

Examples

Embodiment 1

[0027] A process for treating laterite nickel ore with fire-wet combined method, which washes the laterite nickel ore by first scrubbing and then scrubbing, and separates the silicon magnesium nickel ore from the limonite type laterite nickel ore, and the silicon magnesium nickel ore The ferronickel is smelted by pyrotechnics, the steps of which are drying in a rotary kiln, pre-reduction roasting in a rotary kiln, and smelting of ferronickel in a submerged electric furnace. Limonite-type lateritic nickel ore is extracted by sulfuric acid atmospheric pressure leaching method to extract metallic nickel.

Embodiment 2

[0029] A fire-wet combined method for processing laterite nickel ore is characterized in that the laterite nickel ore is first scrubbed and then scrubbed to wash the ore, and the silicon magnesium nickel ore is separated from the limonite type laterite nickel ore. The mine uses pyrotechnics to smelt ferronickel. The steps are to use a rotary kiln to dry, then use a rotary kiln to pre-reduce and roast, and then use a submerged electric furnace to smelt ferronickel. Limonite-type lateritic nickel ore is extracted by sulfuric acid pressure leaching method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com