Method for recycling converter slags

A converter steel slag, mass percentage technology, applied in the field of industrial waste slag recycling, can solve the problems of converter steel slag recycling, the lack of a better way to realize the utilization value, reducing the iron grade of sintered ore, and reducing the output of sintered ore, etc. , The effect of reducing the cost of iron making and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The chemical composition of the broken converter steel slag used in this example is shown in Table 1 at a melting rate of 115 tHM / h.

[0055] The chemical composition (mass percentage, %) of table 1 converter steel slag

[0056] chemical composition

TF

CaO

MgO

SiO2

P

Converter slag

17.8

41.12

8.04

9.06

0.74

[0057] In the case of not using converter steel slag, the content of P in molten iron produced by COREX is 0.084%. The upper limit of the P content in the molten iron in this embodiment is 0.10%. According to the formula [1]:

[0058] m Z (max)=(P L -P)×1000 / Z P [1]

[0059] (0.1-0.084)×1000 / 0.74=21.62kg

[0060] Calculate the maximum use quality M of converter steel slag Z (max)=21.62kg, in the present embodiment, the quality that uses converter steel slag is M Z , [M Z =20.85kg]≤[M Z (max)=21.62kg].

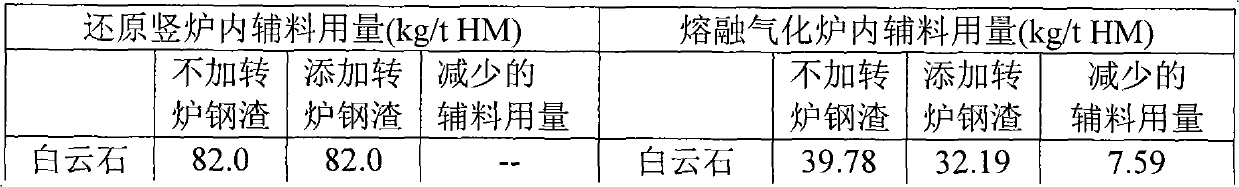

[0061] The composition (mass percentage, %) of auxiliary material ...

Embodiment 2

[0075] The chemical composition of the broken converter steel slag used in this example is shown in Table 4 at a melting rate of 146 tHM / h.

[0076] The chemical composition (mass percentage, %) of table 4 converter steel slag

[0077] chemical composition

TF

CaO

MgO

SiO2

P

Converter slag

17.8

41.12

8.04

9.06

0.74

[0078] In the case of not using converter steel slag, the content of P in molten iron produced by COREX is 0.092%. In this embodiment, the upper limit of P content in molten iron is 0.12%. According to the formula [1]:

[0079] m Z (max)=(P L -P)×1000 / Z P [1]

[0080] (0.12-0.092)×1000 / 0.74=37.84kg

[0081] Calculate the maximum use quality M of converter steel slag Z (max)=37.84kg, in the present embodiment, the quality that uses converter steel slag is M Z , [M Z =37.8kg]≤[M Z (max)=37.84kg].

[0082] The composition (mass percentage, %) of auxiliary material in the table 5COREX ...

Embodiment 3

[0095] At a melting rate of 130 tHM / h, see Table 7 for the chemical composition of the broken converter steel slag used in this example.

[0096] The chemical composition of table 7 converter steel slag (mass percentage, %)

[0097] chemical composition

TF

CaO

MgO

SiO2

P

Converter slag

22.15

48.05

6.7

10.10

1.74

[0098] In the case of not using converter steel slag, the content of P in molten iron produced by COREX is 0.076%. In this embodiment, the upper limit of P content in molten iron is 0.12%. According to the formula [1]:

[0099] m Z (max)=(P L -P)×1000 / Z P [1]

[0100] (0.12-0.076)×1000 / 1.74=25.29kg

[0101] Can calculate the maximum use quality M of converter steel slag Z (max)=25.29kg, in the present embodiment, the quality that uses converter steel slag is M Z , [M Z =25kg]≤[M Z (max)=25.29kg].

[0102] The composition (mass percentage, %) of auxiliary material in the table 8COREX ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com