Grate for biomass particle environment-friendly boiler

A biomass particle and grate technology, applied in the field of boiler manufacturing, can solve problems such as insufficient combustion, inconvenient cleaning of fuel residue, and difficulty in igniting biomass particle fuel, so as to avoid wasting fuel and solve the problem of black smoke from boilers , the effect of shortening the time of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

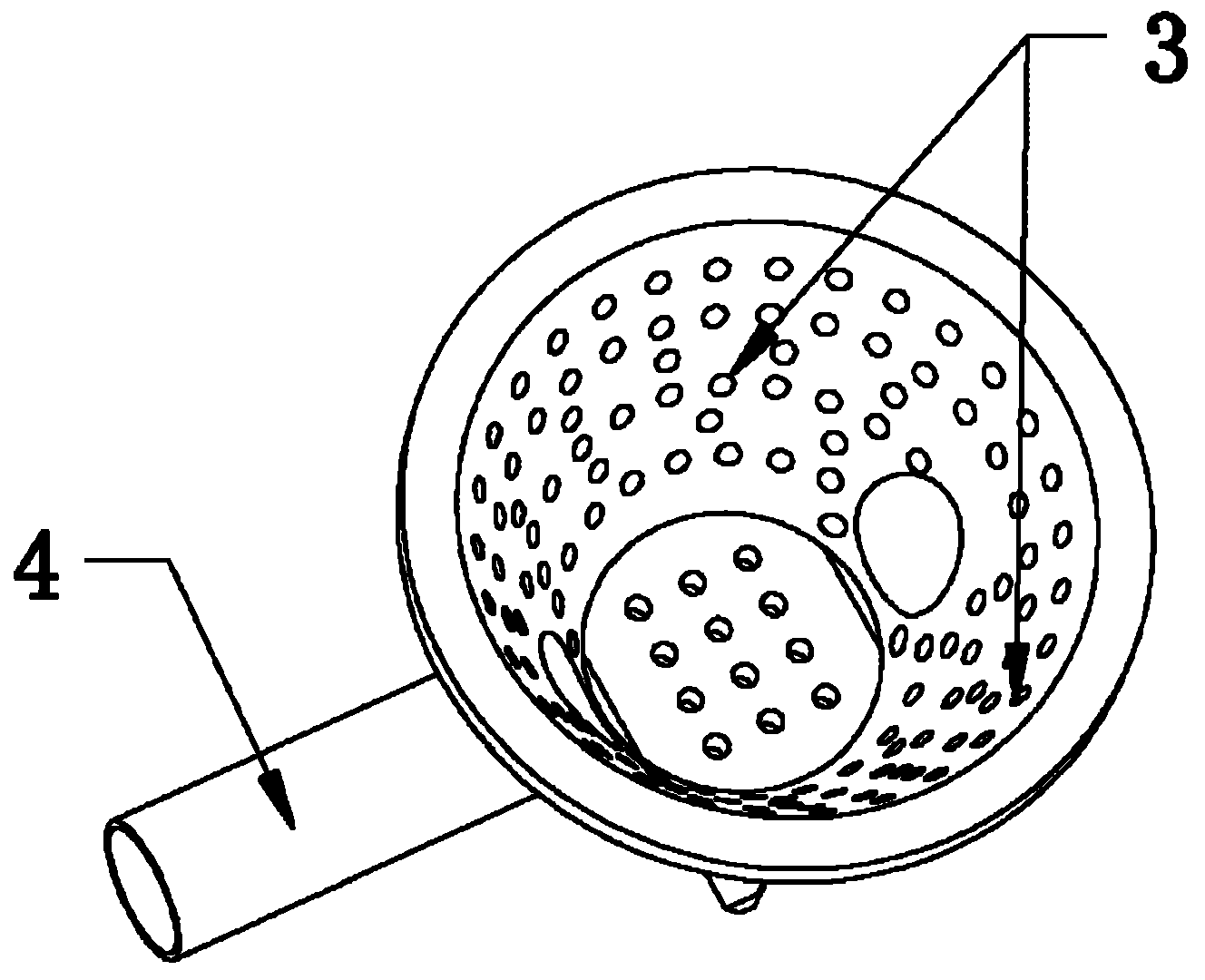

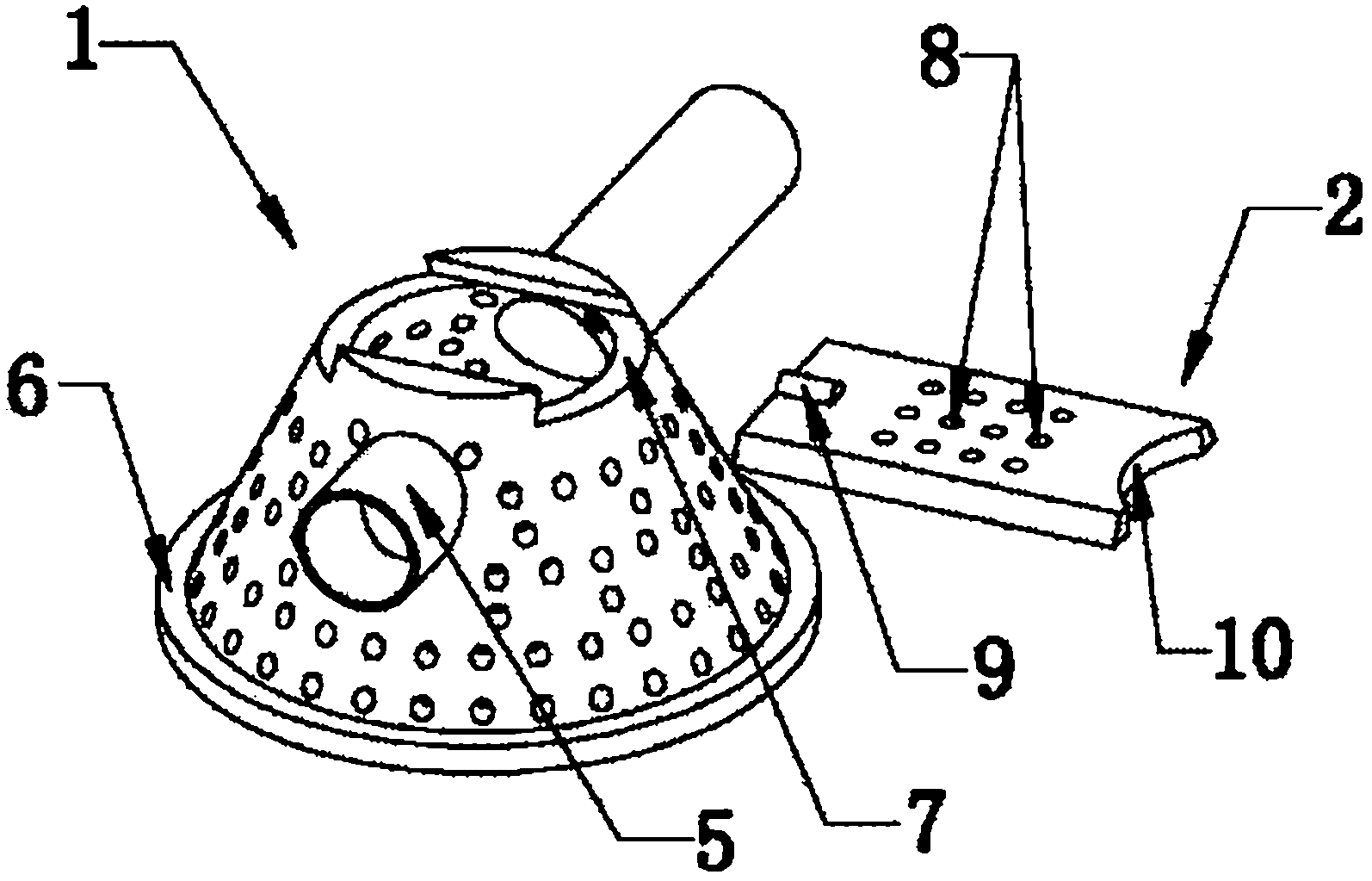

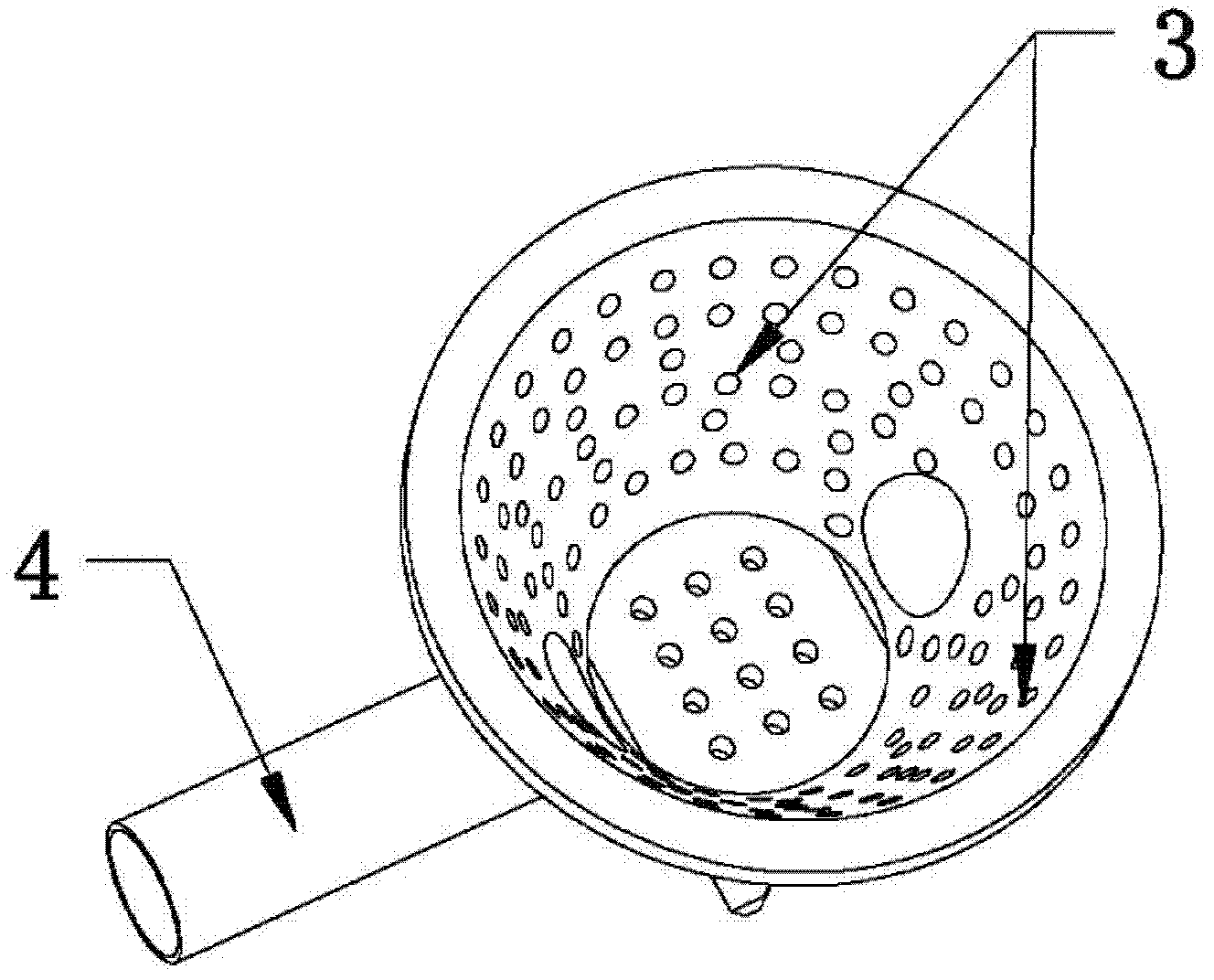

[0013] Such as figure 1 , 2 As shown, a kind of fire grate used for biomass particle environmental protection boiler, including fire grate 1, valve 2, is movable connection between the fire grate 1 and valve 2; the shape of the fire grate 1 is conical, and the fire grate 1 is evenly distributed with a number of ventilation holes A3; one end of the side wall of the grate 1 is welded with an ignited long tube 4, and the other end of the side wall is symmetrically welded with a short tube 5 for ventilation; The support block 6 is provided with a cavity 7 whose shape and size match the valve 2, and the valve 2 is evenly distributed with a number of ventilation holes B8.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com