Method for treating pollutant of workpiece provided with yttrium oxide coating layer

A treatment method, a technology of yttrium oxide, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems such as pollution, reduced wafer production efficiency, easy to drop wafers to be etched, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

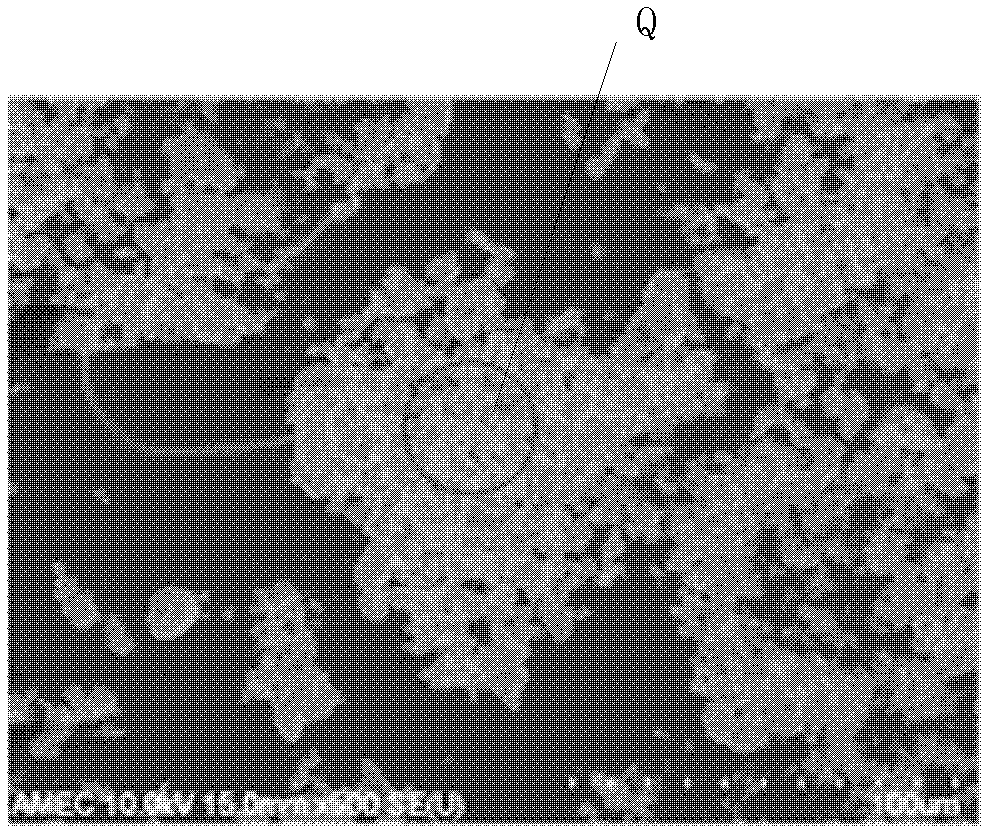

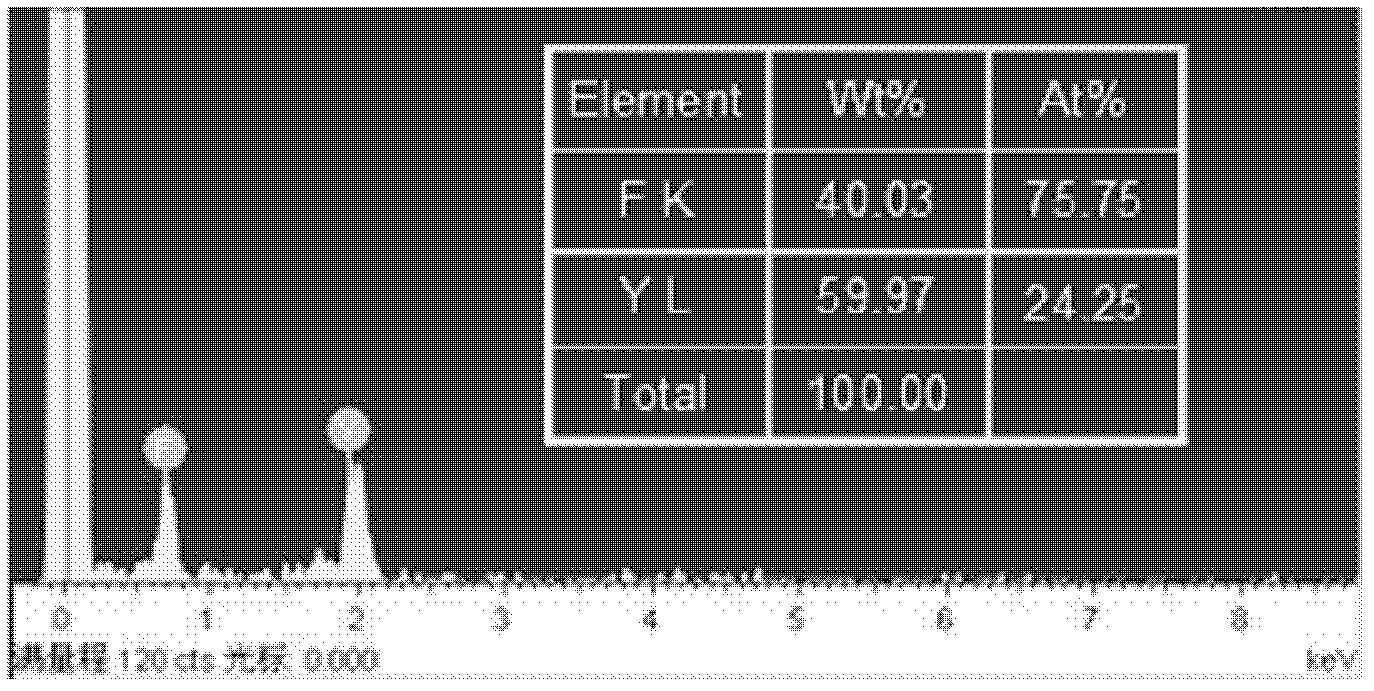

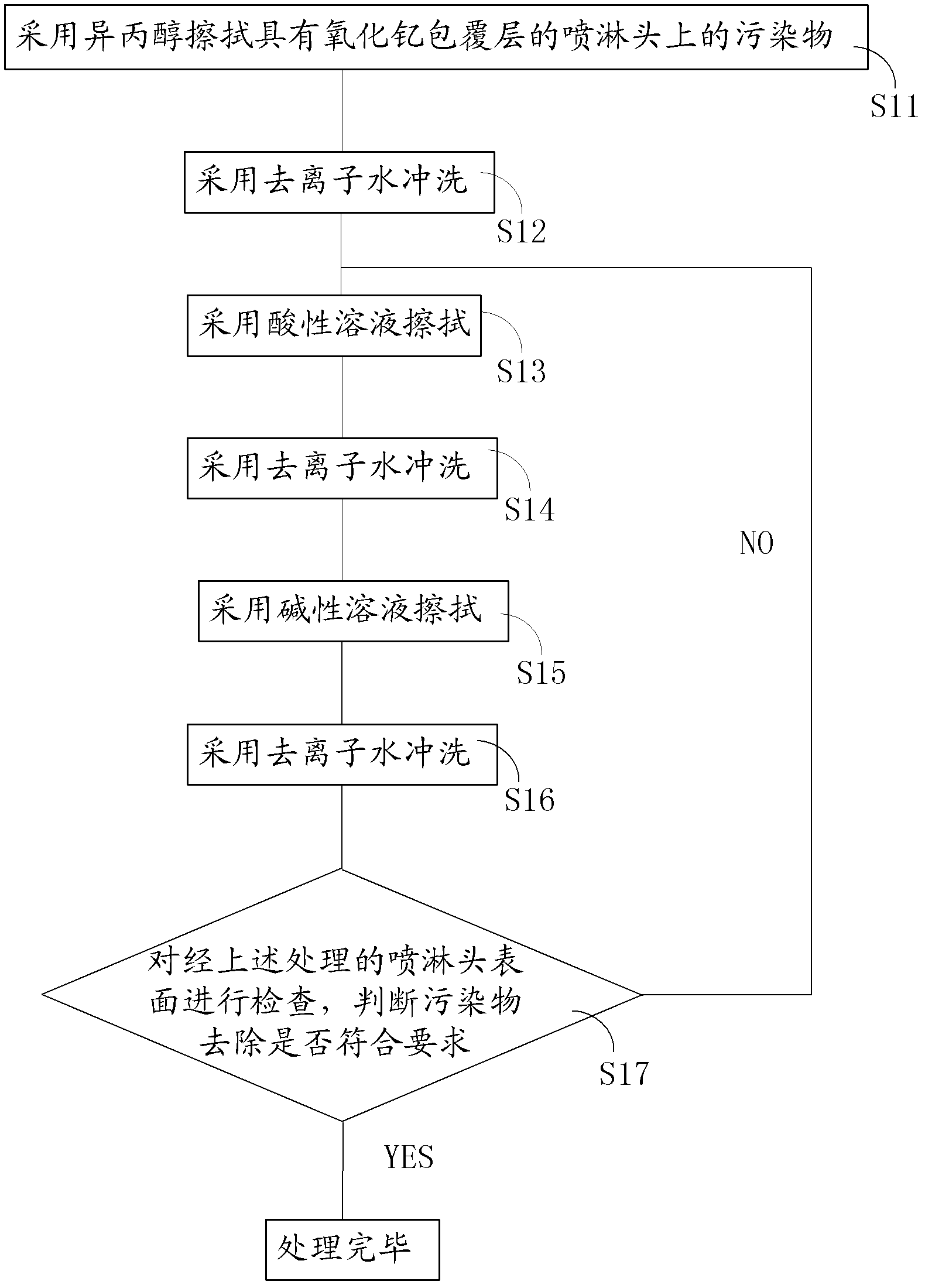

[0044] As described in the background technology, after using the workpiece with yttrium oxide coating for a period of time, some pollutants will be produced on it. The inventor has carried out SEM test and EDS spectrum analysis to the pollutants, and the results are respectively as follows figure 1 and figure 2 As shown, its main components are compounds based on fluorine and yttrium. The present invention proposes to use acidic solution to remove most of the pollutants with poor adhesion, and then rinse with deionized water, so that the contaminated workpiece can be reused. .

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. Since the emphasis is placed upon illustrating the principles of the invention, the drawings are not drawn to scale.

[0046] The following is an example of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com