Stone treatment agent

A treatment agent and stone technology, applied in the field of building materials, can solve the problems of increasing the difficulty of treatment, difficult to clean and remove, and the stone can not keep the color well, and achieve the effect of easy cleaning and removal and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

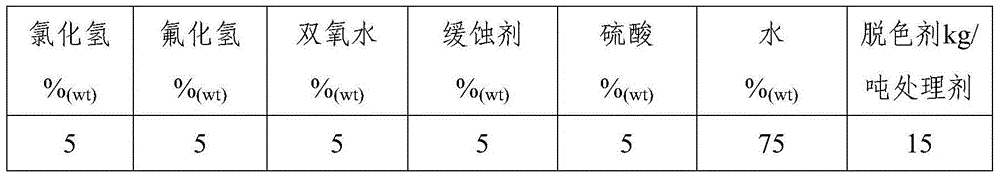

[0023] HEDP is used as a corrosion inhibitor, high polyferric chloride and high polyaluminum chloride 1:1 (mass ratio) are compound decolorizers, and distilled water, hydrogen peroxide, hydrochloric acid, sulfuric acid, hydrofluoric acid, and stone treatment agents are configured.

[0024] Prepare a solution with a mass concentration as shown in Table 1, and treat it with a decolorizing agent:

[0025] Table 1 Example 1 stone treatment agent ratio

[0026]

[0027] The specific method of treating limestone is: configure the above proportioning solution in a 100L glass fiber reinforced plastic container, after cooling, add a decolorizing agent for treatment, after standing for clarification, take 100ml of clear treatment agent, spray evenly on the surface of 10×10cm stone, and leave it at room temperature Under treatment for 45min.

[0028] The variegated treatment agent for this stone has a good treatment effect on sandstone, slate, shale, and limestone. There is no colore...

Embodiment 2

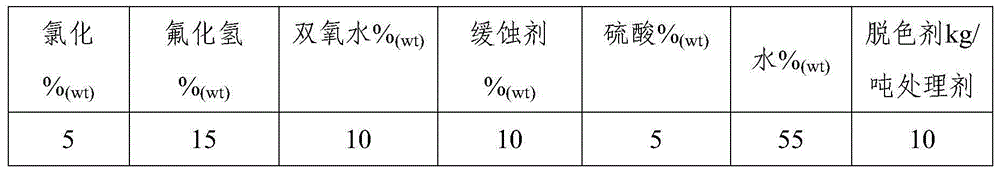

[0030] HEDP and TH-501 (purchased from Shandong Taihe Water Treatment Company) mixed agent (1:1) are used as corrosion inhibitor, high polyferric chloride and high polyaluminum chloride are composite decolorizers (1:1), and distilled water, Hydrogen peroxide, hydrochloric acid, and hydrofluoric acid are configured as stone treatment agents.

[0031] Prepare a solution with a mass concentration as shown in Table 2 and treat it with a decolorizing agent

[0032] Table 2 Example 2 stone treatment agent ratio

[0033]

[0034] The specific method of sandstone treatment is: configure the above proportioned solution in a glass fiber reinforced plastic container, after cooling, add a decolorizing agent for treatment, after standing for clarification, take a clear treatment agent, according to the ratio of 4L treatment agent / m 2 Sandstone is evenly sprayed on the surface of the stone and treated at room temperature for 50 minutes.

[0035] The variegated treatment agent for this ...

Embodiment 3

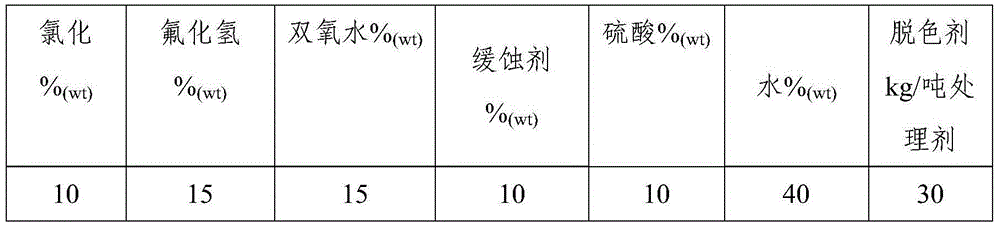

[0037] POCA and polyacrylic acid (2:1) are used as corrosion inhibitors, cationic polyacrylamide and high polyaluminum chloride composite decolorizer (2:1), and distilled water, hydrogen peroxide, hydrochloric acid, and hydrofluoric acid are used as stone treatment agents.

[0038] The mass concentration of preparation stone material treatment agent is as follows the solution of table 3, and handles with decolorizing agent:

[0039] Table 3 Example 3 stone treatment agent ratio

[0040]

[0041] The specific method for treating granite is: configure the above proportioned solution in a glass fiber reinforced plastic container, add a decolorizer after cooling, and after standing for clarification, take a clear treatment agent, according to the ratio of 3L treatment agent / m 2 Granite is evenly sprayed on the surface of the stone and treated at room temperature for 50 minutes.

[0042] The variegated treatment agent for this stone has a good treatment effect on granite and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com