Preparation method of low-ash mesophase pitch

A technology of mesophase pitch and low ash content, which is applied in the field of preparing mesophase pitch by thermal polymerization, can solve the problems of difficulty in purifying coal pitch, and achieve the effects of low raw material cost, low energy consumption and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

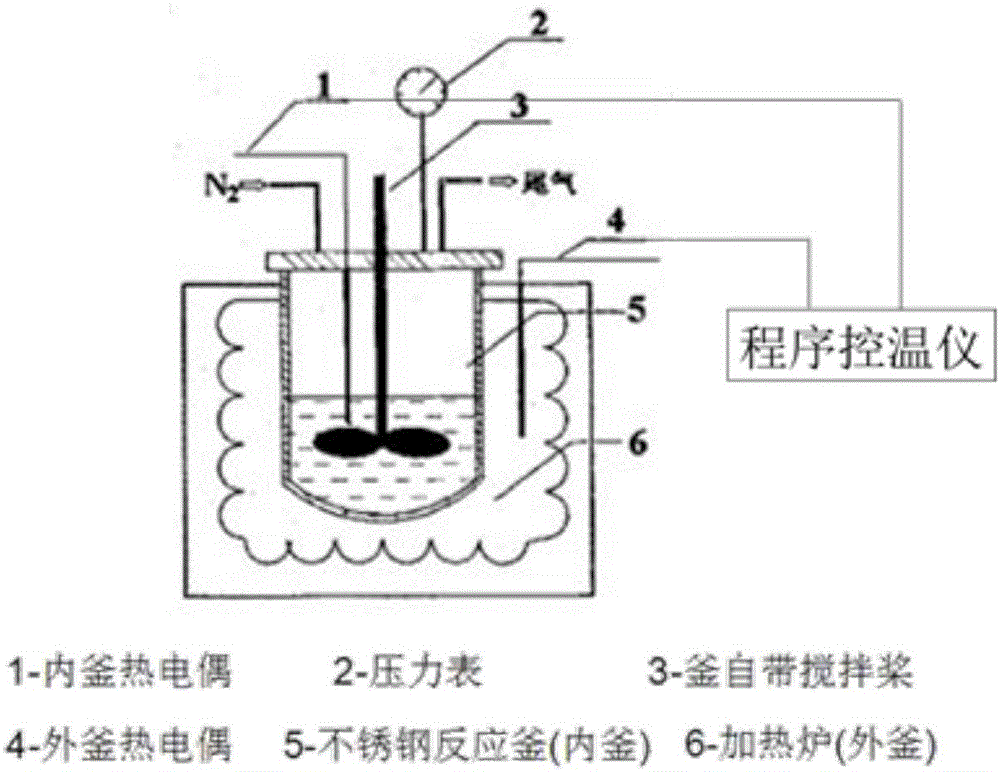

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Gravity sedimentation of coal tar in a constant temperature water bath at 75°C for 4h, and then centrifuged at a speed of 5000r / min for 3min, after centrifugation, filtered through a filter with a pore size of 2 microns, and then kept at 80°C for 1h while stirring Demulsification treatment, then heating to 120°C to remove water and ammonium salts, the measured ash content of the purified coal tar is 0.0075%. Put 400ml of purified coal tar into a reactor with a capacity of 1L, blow nitrogen to remove the air, then continue to blow nitrogen to make the initial pressure inside the reactor reach 1Mpa, set the temperature at 4°C / min to 400°C, and at the same time, set the temperature at 400r / min. Stir at a speed of 1 min, the pressure changes with the change of temperature, and keep warm for 5 hours. After the heat preservation is over, release the pressure, blow nitrogen for 20 minutes to remove light components, stop stirring, and cool to obtain purified coal tar...

Embodiment 2

[0013] Example 2: The gravity settling time of coal tar was extended to 12 hours, and other conditions were the same as in Example 1. The yield of mesophase pitch obtained was 42%, the softening point was 230°C, the mesophase content was 98%, and the ash content was 50ppm.

Embodiment 3

[0014] Example 3: The gravity settling time of coal tar was extended to 24 hours, and the other conditions were the same as in Example 1. The softening point of the obtained mesophase pitch was 230° C., the mesophase content was 98%, and the ash content was 45 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com