The synthetic method of 2,3,3,3-tetrafluoropropene

A synthetic method, the technology of tetrafluoropropene, applied in two fields, can solve the problems of unreported, less research on the preparation of HFO-1234yf, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Step a) Catalyst Ni-Cu-La for preparing 1,1,1,2,3,3-hexafluoropropane by hydrogenation reduction of 1,1,1,2,3,3-hexafluoropropene 2 o 3 / Al 2 o 3 Preparation of:

[0046] The first step is to impregnate the auxiliary agent, weigh La(NO 3 ) 3 ·nH 2 O2.40g is added to 24ml deionized water to prepare La(NO 3 ) 3 solution, add 25g20-40 purpose Al to the solution 2 o 3 , impregnated at room temperature for 40h, then dried overnight at 150°C, and calcined at 500°C for 5h.

[0047] In the second step of impregnation, weigh 29.72gNi(NO 3 ) 2 ·6H 2 O, 6.84gCu(NO 3 ) 2 ·3H 2 O, washed into 20ml deionized water, prepared into a mixed solution of the two, the solid prepared in the first step was added to the mixed solution for immersion, drying and calcination, and the treatment conditions were the same as the first step, thereby preparing the catalyst Ni -Cu-La 2 o 3 / Al 2 o 3

[0048] Take a certain amount of catalyst and put it into a reaction tub...

Embodiment 2

[0050] Embodiment 2: step a) catalyst Ni-Cu-CoO / TiO 2 Preparation of:

[0051] Weigh Co(NO 3 ) 2 ·6H 2 O2.22g is added to 12ml deionized water to prepare Co(NO 3 ) 2 Solution, add 25g 20-40 purpose TiO to the solution 2 , impregnated at room temperature for 40h, then dried overnight at 150°C, and calcined at 500°C for 5h.

[0052] In the second step of impregnation, weigh 7.43gNi(NO 3 ) 2 ·6H 2 O, 11.41gCu(NO 3 ) 2 ·3H 2 O, washed into 12ml deionized water, prepared into a mixed solution of the two, the solid prepared in the first step was added to the mixed solution for immersion, drying and calcination, and the treatment conditions were the same as the first step, thereby preparing the catalyst Ni -Cu-CoO / TiO 2 .

[0053] Catalyst reduction and hydrogenation activity testing methods are the same as in Example 1. Pass hydrogen-nitrogen mixed gas (wherein hydrogen volume ratio is 10%), program temperature reduction, from room temperature to 250 ° C, heating rate ...

Embodiment 3

[0054] Embodiment 3: step b) the preparation of the chromium oxide of catalyst fluorination

[0055] Prepare chromium hydroxide with chromium nitrate solution and ammonia water, filter, wash with water, dry at 90°C, use a tablet molding machine to make a cylindrical shape with a diameter of 3mm and a length of 3mm, and put it into a Hastelloy C-22 In the reaction tube, under nitrogen flow, heat at 450°C for 2h to activate it, then lower the temperature to 200°C, supply fluoride anhydride diluted with nitrogen, and perform fluorination treatment for 5h. Chromium trioxide fluoride is prepared.

[0056] 10 g of the catalyst fluorinated chromium trioxide arranged above was charged into a reaction tube made of Hastelloy C-22 with an inner diameter of 2 cm and a length of 40 cm, and heated to 400° C. while flowing nitrogen gas.

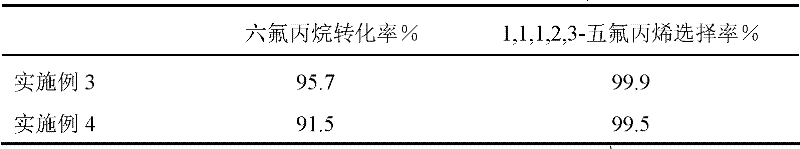

[0057] Change nitrogen into 1,1,1,2,3,3-hexafluoropropane, and pass it into the reaction tube at a flow rate of 30cc / min. The gas at the outlet of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com