Composite diaphragm and method for preparing same

A composite diaphragm and polymer technology, applied in the direction of separator/film/diaphragm/spacer components, electrical components, circuits, etc., can solve hidden dangers, polyolefin diaphragms have safety problems, achieve low cost and low pollution, and improve Effect of wettability and improvement of thermal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

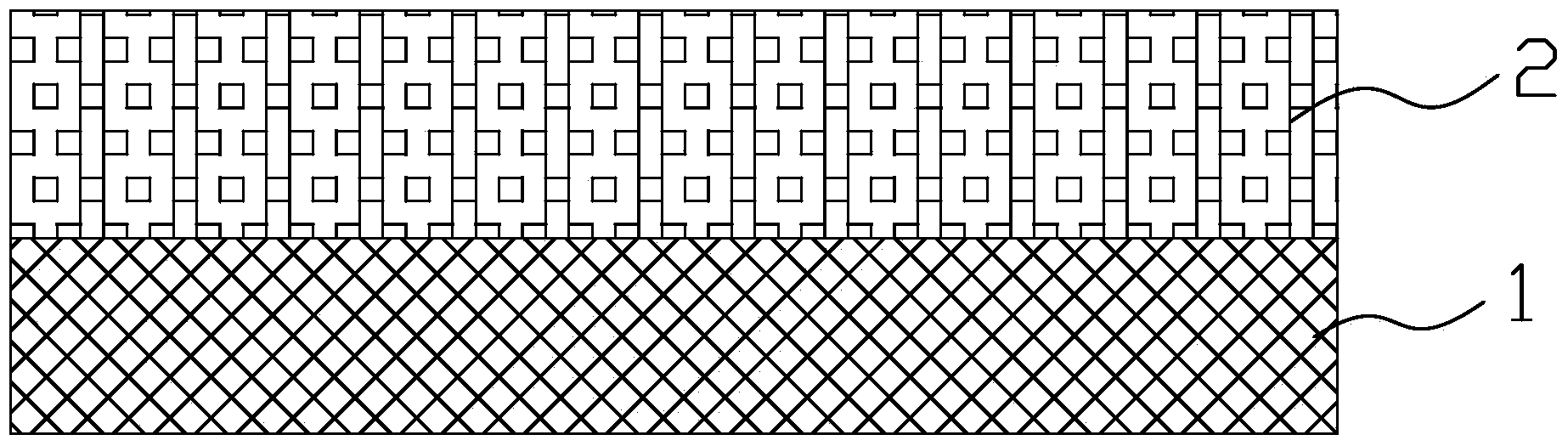

[0024] refer to figure 1 , a composite diaphragm, comprising a stacked support layer 1 and an organic / inorganic particle blend coating layer 2, the preparation method of which comprises the following steps:

[0025] 1) Using deionized water as a solvent, dissolve water-based adhesives, surfactants, dispersants, thickeners, etc. under normal temperature and high-speed stirring to form a solution; then add polymer particles and inorganic particles, and stir evenly at high speed , made into water-based slurry; the mass percentage of each substance in the slurry is: 0.1%-2% water-soluble polymer thickener, 0.01%-2% water-based dispersant, 0.01%-2% surfactant , 0.1%~5% water-based adhesive, 5%~50% polymer particles and inorganic particles, 50%~83% deionized water;

[0026] 2) Using micro gravure roll coating, the water-based slurry prepared in the first step is coated on the support layer diaphragm, and the coating speed is 5-100m / min;

[0027] 3) The coating film obtained in the...

Embodiment 1

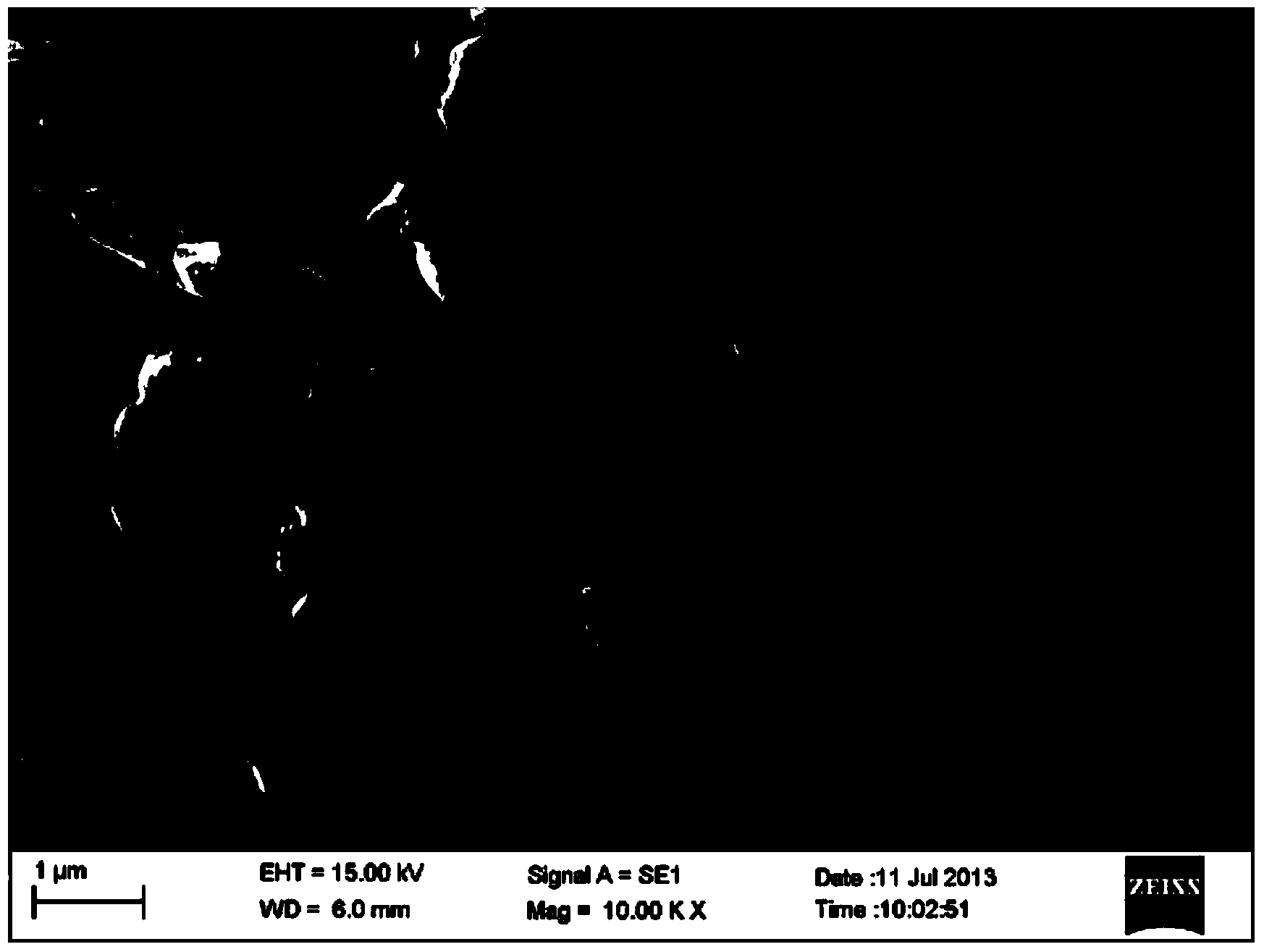

[0031] The weight ratio of organic / inorganic mixed particles in the slurry: deionized water = 100: 200, PVDF-HFP: Al 2 o 3 =20:80. First, add the adhesive PVA and tackifier CMC into deionized water, stir at 300r / min at room temperature for 20min until completely dissolved, wherein the weight ratio of PVA and CMC is PVA:organic / inorganic mixed particles=4.5:100 , CMC:organic / inorganic hybrid particles=1.5:100. Then add fluorocarbon surfactant, water-based dispersant polyoxypropylene mannitol dioleate and organic / inorganic mixed particle powder to the above solution in sequence, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min , the slurry preparation is completed. Among them, fluorocarbon surfactant: organic / inorganic mixed particles=0.2:100, polyoxypropylene mannitol dioleate: organic / inorganic mixed particles=0.6:100. The weight average molecular weight of PVDF-HFP is about 370,000, the particle size is 100-300nm, Al 2 o 3 Powder D50 = 1.0 ...

Embodiment 2

[0033] The weight ratio of organic / inorganic mixed particles in the slurry: deionized water = 100: 200, PVDF-HFP: Al 2 o 3=38:62. First, add the adhesive PVA and tackifier CMC into deionized water, stir at 300r / min at room temperature for 20min until completely dissolved, wherein the weight ratio of PVA and CMC is PVA:organic / inorganic mixed particles=4.5:100 , CMC:organic / inorganic hybrid particles=1.5:100. Then add fluorocarbon surfactant, water-based dispersant polyoxypropylene mannitol dioleate and organic / inorganic mixed particle powder to the above solution in sequence, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min , the slurry preparation is completed. Among them, fluorocarbon surfactant: organic / inorganic mixed particles=0.2:100, polyoxypropylene mannitol dioleate: organic / inorganic mixed particles=0.6:100. The weight average molecular weight of PVDF-HFP is about 370,000, the particle size is 100-300nm, Al 2 o 3 Powder D50 = 1.0 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com