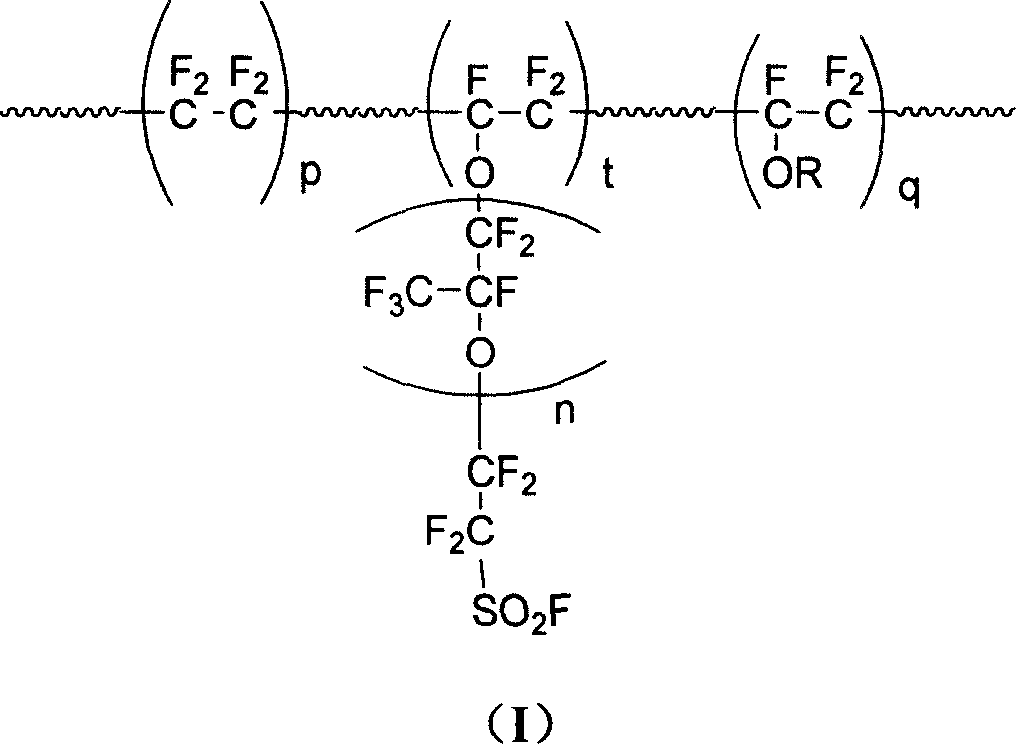

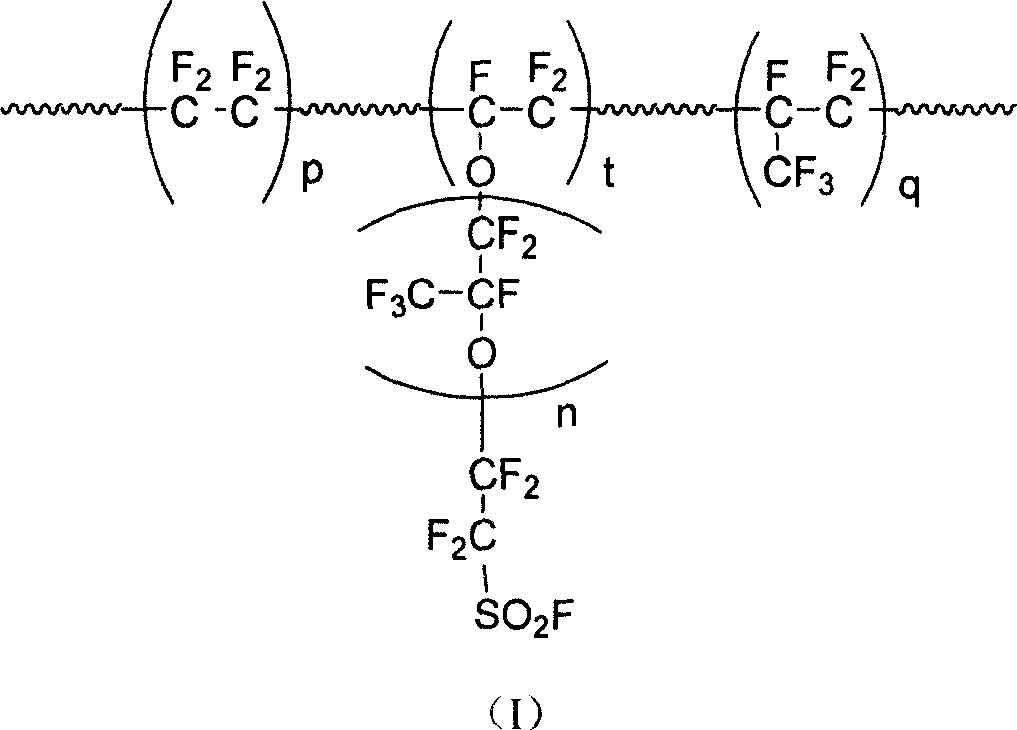

Polymer of containing fluorin, and application as material of ion exchange fiber

A technology of ion exchange and fluororesin, applied in the direction of melt spinning, etc., to solve technical problems, increase effective area, reduce membrane resistance and cell voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

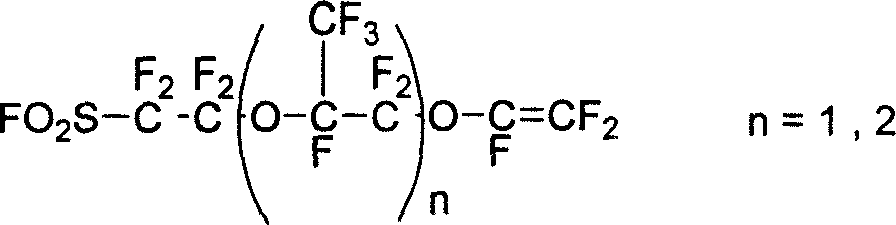

[0028] Example 1: Preparation of monomer perfluorosulfonyl vinyl ether

[0029] Perfluorosulfonyl vinyl ether (n=2, molecular weight is 612g / mol), molecular formula is:

[0030]

[0031] The synthesis method is as follows:

[0032] Tetrafluoroethylene and liquid SO 3 Reaction to prepare sultone, the purified sultone product is catalyzed by a composite fluoride ion catalyst and reacted with hexafluoroepoxy to prepare a perfluoroacyl fluoride product with a sulfonyl fluoride end group, which has a sulfonyl fluoride end group Perfluoroalkene ether compounds can be prepared by cracking and decarboxylation of perfluoro compounds at high temperature.

Embodiment 2

[0034] Add 23.2g perfluoroalkyl ether containing melamine structure and 185g distilled water in the 1L high-pressure stainless steel reaction kettle that is equipped with stirring, heating, nitrogen feed device as sub-example dispersant / solvent, perfluorosulfonyl vinyl ether 6.12g ( n=2) and 0.2g of benzoyl peroxide, replace the air in the reactor with high-purity nitrogen, pass through 95g of tetrafluoroethylene and 6g of hexafluoropropylene, heat up to 80°C and stir for 6h, cool down after the reaction, and release the gas , make the pressure in the kettle become normal pressure, release the product from the discharge pipe, precipitate in a large amount of water, filter to obtain a powder product, wash with distilled water several times, and dry under vacuum at 100°C. Dispersant and water phase, liquid separation and recycling.

[0035] The prepared polymer material was tested by fluorine NMR to show that the weight percentage of perfluorosulfonyl vinyl ether was 5.42%, the ...

Embodiment 3

[0037] Add 23.2g perfluoroalkyl ether containing melamine structure and 185g distilled water as dispersant / solvent in the 1L high-pressure stainless steel reactor that is equipped with stirring, heating, nitrogen feed device, perfluorosulfonyl vinyl ether 6.3g (n =2) and 0.2g benzoyl peroxide, replace the air in the reactor with high-purity nitrogen, feed 100.8g tetrafluoroethylene and 4.84g hexafluoropropylene, heat up to 80°C and stir for 3h, cool after the reaction, and put Make the pressure inside the kettle become normal pressure, release the product from the discharge pipe, precipitate in a large amount of water, filter to obtain a powder product, wash with distilled water several times, and dry under vacuum at 100°C. Dispersant and water phase, liquid separation and recycling.

[0038] The prepared polymer material has a thermal decomposition temperature of 374° C. by DTA test, and a melting temperature of 265° C. by DSC test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com