Elevator traction rope clamping device and rope cutting method applying same

An elevator traction and traction technology, which is applied in the field of elevator traction rope clamping device and rope cutting, can solve the problems of affecting maintenance efficiency, low work efficiency, and large manpower consumption, so as to ensure personal safety, reduce labor, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

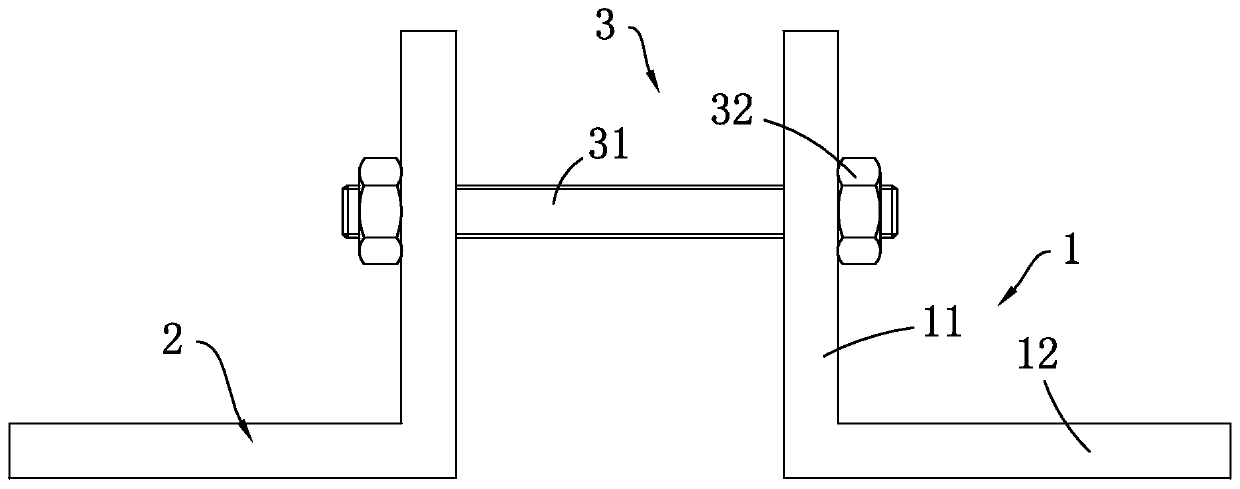

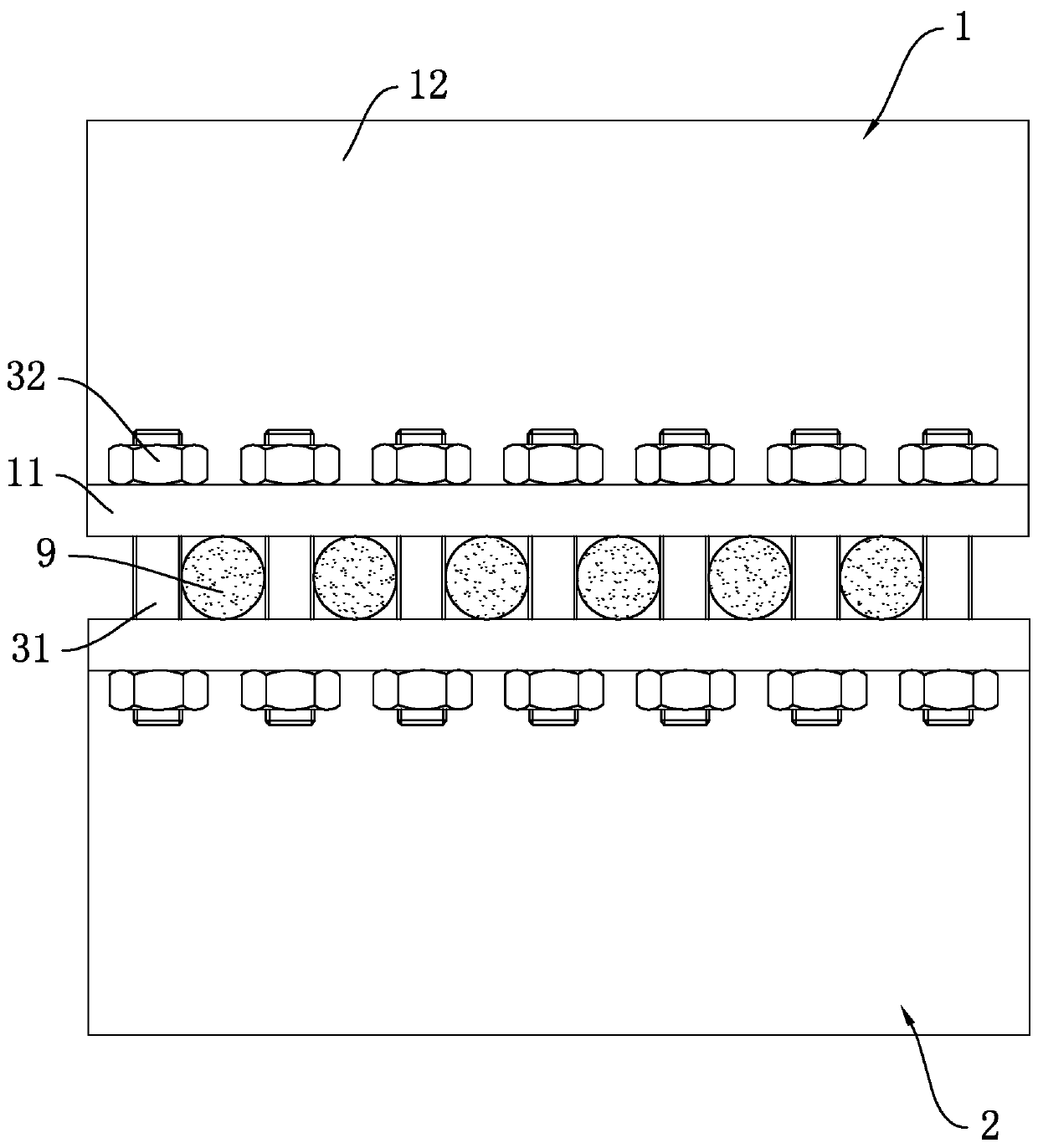

[0048] refer to figure 1 , The present invention discloses an elevator traction wire rope clamping device, which mainly includes a first clamping plate 1 , a second clamping plate 2 , and several connecting components 3 . The first splint 1 and the second splint 2 are arranged opposite to each other, and several connecting assemblies 3 connect the first splint 1 and the second splint 2 in parallel with each other, and are constructed between the first splint 1 and the second splint 2 to form several During the installation interval, the traction wire ropes 9 are clamped by the first clamp plate 1 and the second clamp plate 2 after passing through the installation space in a one-to-one correspondence.

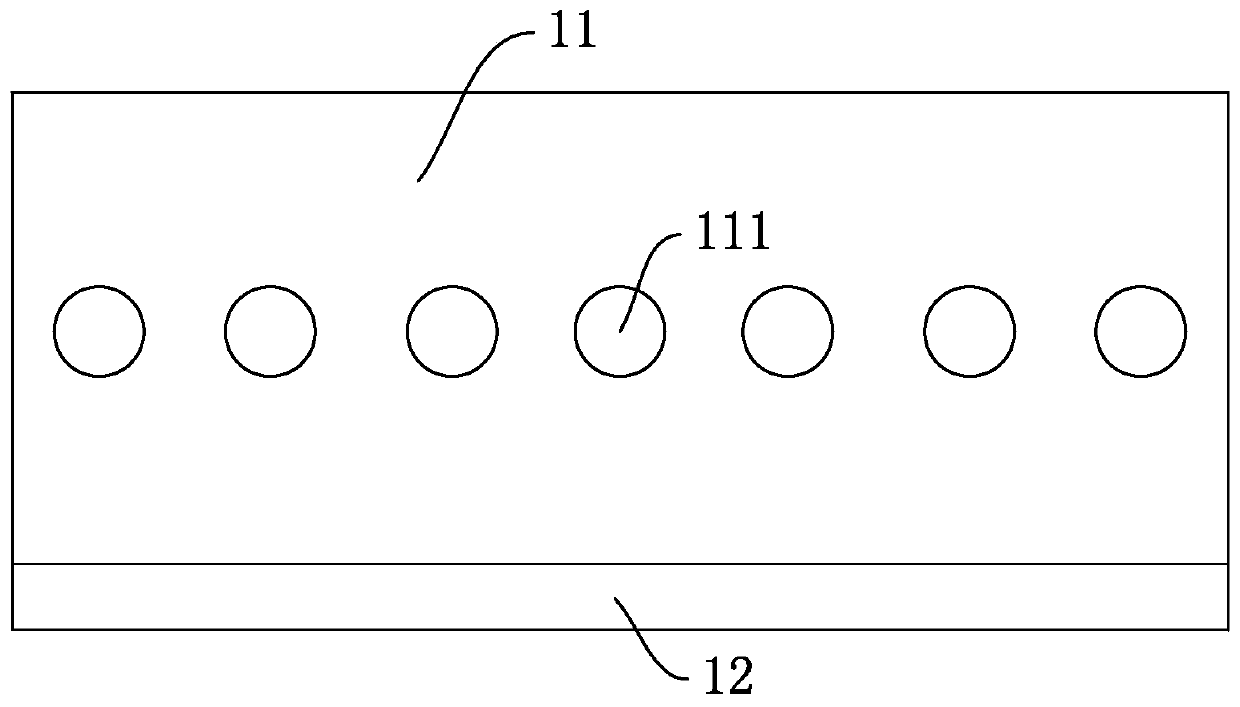

[0049] combine figure 2 Specifically, the first splint 1 and the second splint 2 can be made of angle steel, both of which have a mutually perpendicular fixing part and an engaging part 12, and the fixing parts of the two are provided with several concentric parts at equal int...

Embodiment 2

[0053] refer to Figure 4 , the present invention also discloses a rope cutting method using the elevator traction wire rope device 10 in the first embodiment, and the method includes the following steps:

[0054] Step 1. Measure the distance between the counterweight 30 and the buffer if it exceeds the installation standard range, and calculate the length to be intercepted.

[0055] Specifically, we take an elevator with a 2:1 suspension ratio as an example. For example, for a passenger elevator with a 5-story station, the traction wire rope 9 is about 50m long. If it is suspended at 2:1, the rope length is about 100m. , using spring buffer 20, the buffer distance is 150-400mm. First, arrange a maintenance person in the machine room to drive the car 40 to the top floor at a slow speed. After leveling, turn the elevator to the maintenance state, and notify the waiting maintenance personnel to enter the pit to measure the distance from the counterweight 30 lower beam impact pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com