Arrangement device for strip-shaped materials with asynchronous feeding speeds after cutting off

A material and strip-shaped technology, which is applied in the field of strip-shaped material sorting devices, can solve the problems of irregular feeding speed and difficulty in automation, and achieve the effects of no crossover, ensuring safety gaps, and enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

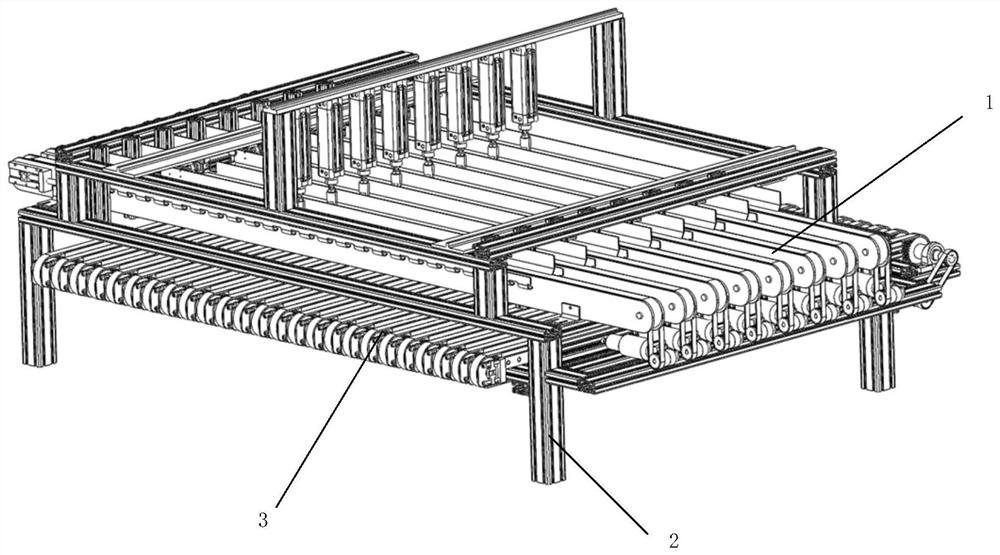

[0038] as attached figure 1 As shown, the monolithic device is composed of a monolithic unit 1, an aluminum alloy bracket 2 and a material conveying belt 3.

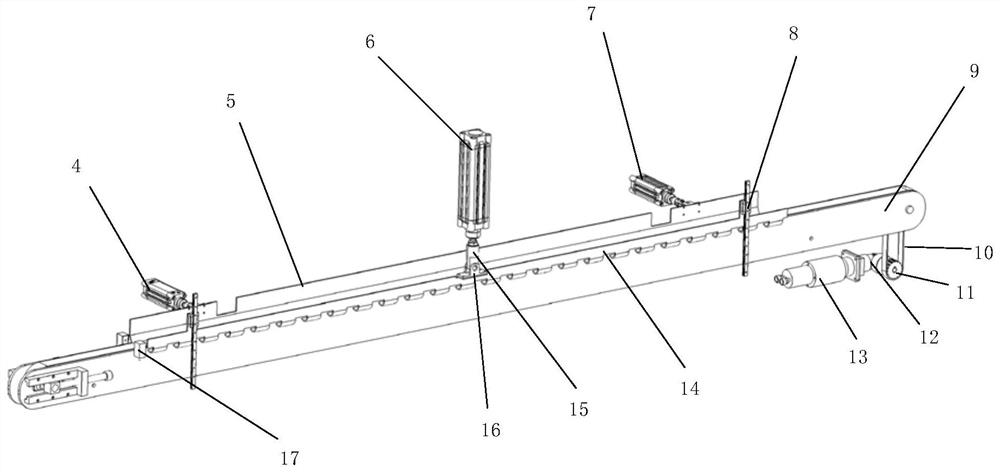

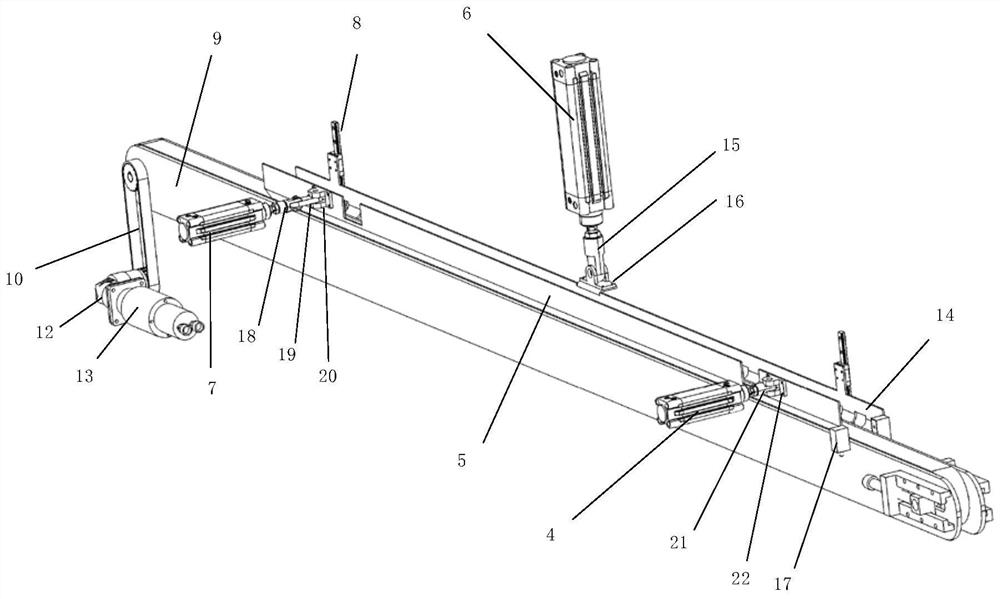

[0039] as attached figure 2 and image 3 As shown, each group of monolithic unit 1 consists of a first pusher plate cylinder 4, a pusher plate 5, a supporting plate cylinder 6, a second pusher plate cylinder 7, a slide rail 8, a monolithic conveyor belt 9, and a monolithic unit Synchronous belt 10, timing belt pulley 11 of monolithic unit, reducer 12 of monolithic unit, servo motor 13 of monolithic unit, supporting plate 14, supporting plate cylinder joint 15, cylinder-supporting plate connecting piece 16, photoelectric sensor 17, The second push plate cylinder joint 18, the material pushing mechanism connector 19, the second cylinder-the push plate connector 20, the first push plate cylinder joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com