USB connector

A technology for connectors and welding strips, applied in the direction of connection, fixed connection, and parts of connection devices, can solve problems such as increased production cost, high product defect rate, adverse effects on transmission performance and mechanical performance, etc., to improve product performance. , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

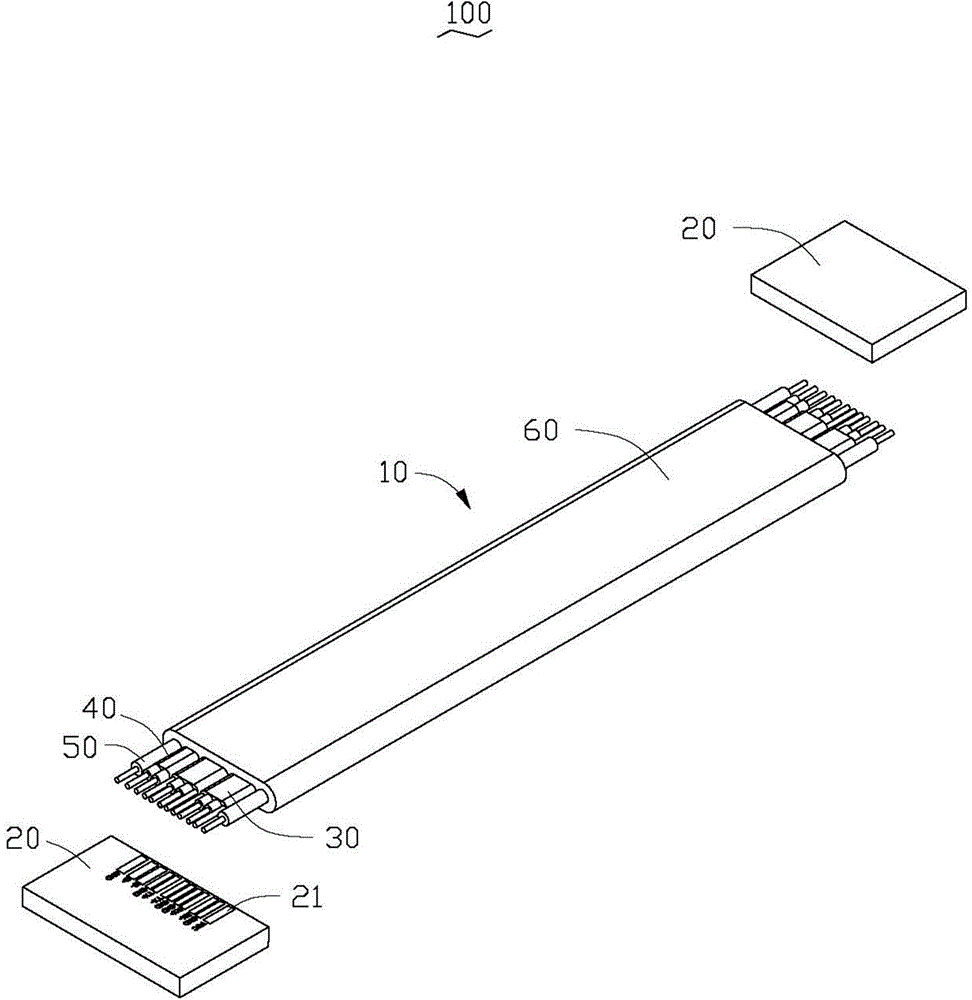

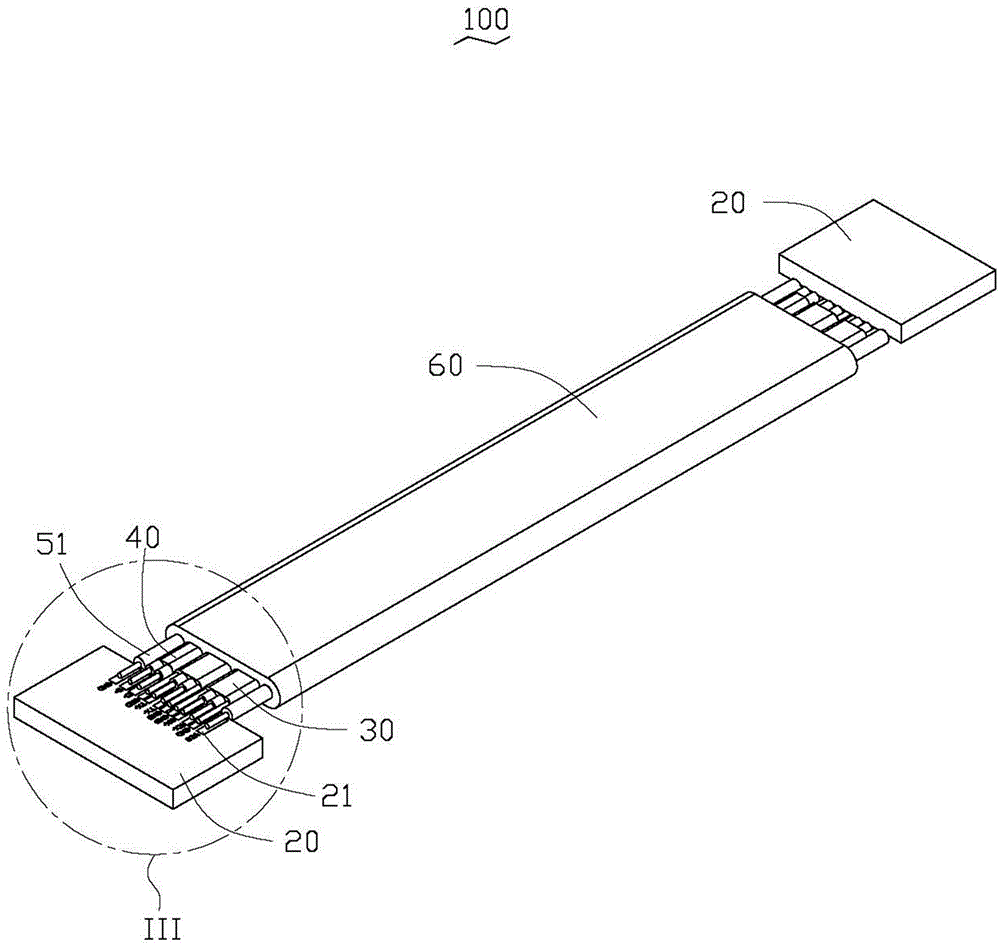

[0020] See figure 1 In a preferred embodiment of the present invention, a USB connector 100 is used for data transmission, and includes two plug connectors (not shown in the figure) and a cable 10.

[0021] See figure 2 The plug connector includes an adapter plate 20, and a plurality of welding bars 21 are provided on the adapter plate 20, and the welding bars 21 are used to connect the cable 10 and the adapter plate 20.

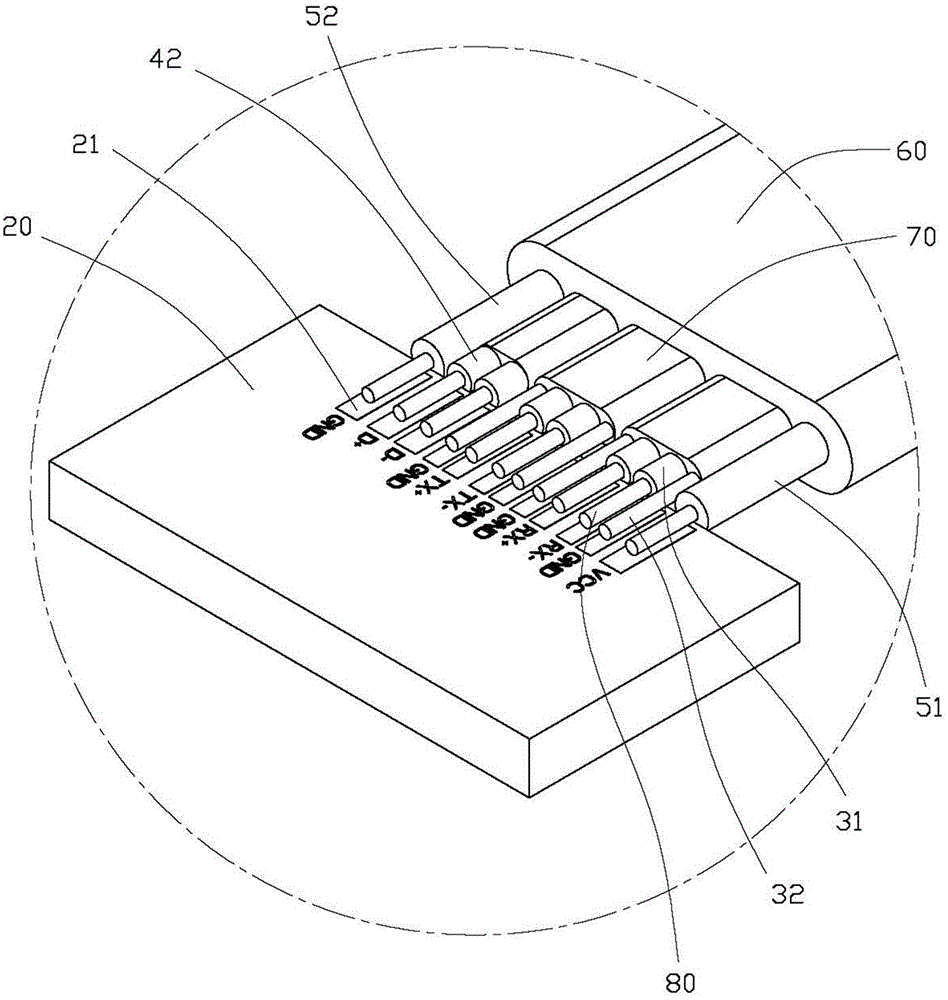

[0022] See figure 2 and image 3 , The cable 10 is flat, the cable 10 includes a plurality of signal line modules and a wire cover 60, the signal line module includes two first signal line modules 30, a second signal line module 40 and a power cord module 50. The first signal line module 30 includes a shielding sleeve 70, two first core wires 31, and two ground wires 32. The two ground wires 32 are located on both sides of the two first core wires 31, respectively. 32 and the two first core wires 31 are arranged in parallel to each other, the two ground wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com