Production technology for manufacturing automobile cylinder by aid of crankcase core module

A technology of crankcase core and automobile cylinder block, which is applied in the direction of manufacturing tools, cores, casting molding equipment, etc., can solve the problems of staying in the cavity, product scrapping, large quantities, etc., and achieve the effect of improving molding quality and stabilizing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should understand that following specific embodiment is only for illustrating the present invention and is not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the present invention Modifications in various equivalent forms fall within the scope defined by the appended claims of the present application.

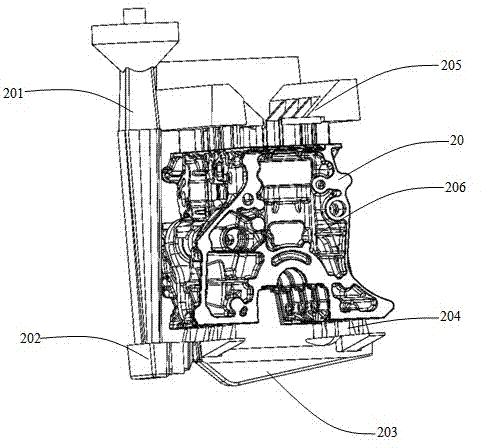

[0018] see figure 1 As shown, the present invention discloses a production process of using a crankcase core module to manufacture an automobile cylinder block. Firstly, a crankcase core module is provided. The runner 203, the sprue 201 located on the side of the crankcase core 20 and extending from top to bottom, the filter 202 connecting the sprue 201 and the runner 203, the sprue 203 and the crankcase core 20 The inrunner 204 and the overflow riser 205 installed above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com