Spiral stirrup fixing device

A technology of spiral stirrups and fixing devices, applied in the directions of packaging, transportation and packaging, external frame, etc., can solve the problems of time-consuming, labor-intensive, low work efficiency, inconvenience, etc., to reduce production costs, improve production efficiency, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

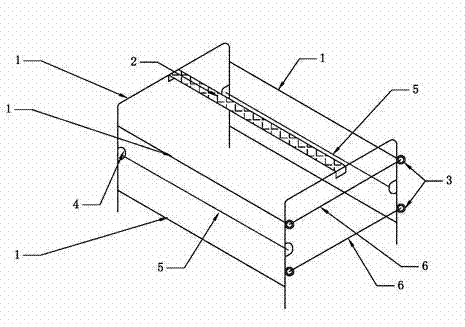

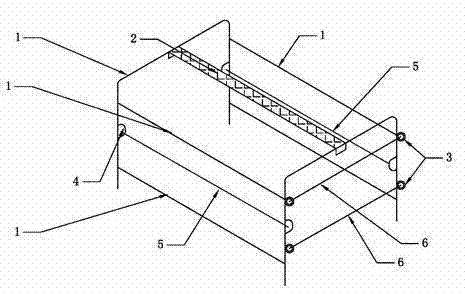

[0012] Such as figure 1 As shown, a spiral stirrup fixing device includes a main frame 1 of the device, and the main frame 1 of the device is a U-shaped groove structure, that is, a U-shaped groove-shaped skeleton is made of steel bars and other materials, and the U-shaped groove opening is opened when in use. Orientation is used against the spiral stirrup. The spiral stirrup fixing device also includes a stirrup clamping device, the stirrup clamping device is a stirrup fixing intubation tube 4 fixed on the device main frame 1 and a splint 5 that can pass through the stirrup fixing insertion tube 4, and the stirrup fixing The intubation tube 4 is arranged on two vertical sides on the same side elevation of the device main frame 1, and is symmetrically distributed, and the splint 5 passes therethrough, and the effect of the splint 5 is to clamp the spiral stirrup.

[0013] The spiral stirrup fixing device also includes a main rib positioning device, and the main rib positionin...

Embodiment 2

[0017] A spiral stirrup fixing device, comprising a main frame 1 of the device, the main frame 1 of the device is a U-shaped groove structure, that is, a U-shaped groove-shaped skeleton is made of steel bars and other materials, and the opening direction of the U-shaped groove faces the Spiral stirrups are used. The spiral stirrup fixing device also includes a stirrup clamping device, the stirrup clamping device is a stirrup fixing intubation tube 4 fixed on the device main frame 1 and a splint 5 that can pass through the stirrup fixing insertion tube 4, and the stirrup fixing The intubation tube 4 is arranged on two vertical sides on the same side elevation of the device main frame 1, and is symmetrically distributed, and the splint 5 passes therethrough, and the effect of the splint 5 is to clamp the spiral stirrup.

[0018] The spiral stirrup fixing device also includes a sign 2 arranged on the top of the main frame 1 of the device. The signboard 2 is used to indicate the ...

Embodiment 3

[0022] A spiral stirrup fixing device, comprising a main frame 1 of the device, the main frame 1 of the device is a U-shaped groove structure, that is, a U-shaped groove-shaped skeleton is made of steel bars and other materials, and the opening direction of the U-shaped groove faces the Spiral stirrups are used. The spiral stirrup fixing device also includes a stirrup clamping device, the stirrup clamping device is a stirrup fixing intubation tube 4 fixed on the device main frame 1 and a splint 5 that can pass through the stirrup fixing insertion tube 4, and the stirrup fixing The intubation tube 4 is arranged on two vertical sides on the same side elevation of the device main frame 1, and is symmetrically distributed, and the splint 5 passes therethrough, and the effect of the splint 5 is to clamp the spiral stirrup.

[0023] The use of the spiral stirrup fixing device, after the spiral stirrup is wound into shape, on the spiral stirrup winding drum, first put the U-shaped mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com