Double-layer rigid pipeline structure of water purifier provided with upper module and lower filter container bin

A technology of rigid pipelines and water purifiers, applied in the fields of filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of waterway switcher difficulties, affect technology promotion and popularization, increase manufacturing difficulty and cost, etc., and achieve Effect of Rigid Piping Simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

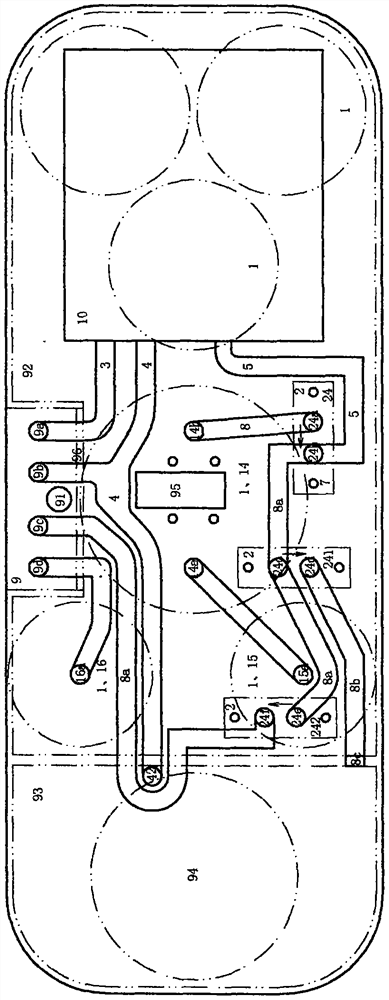

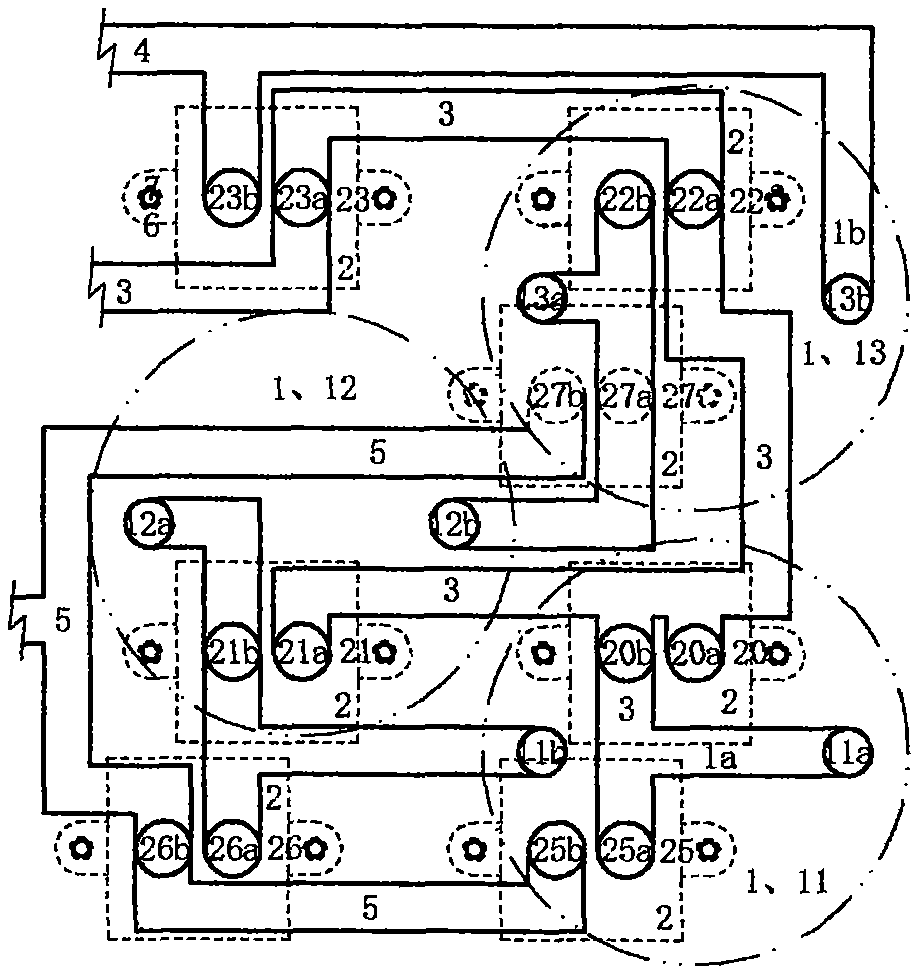

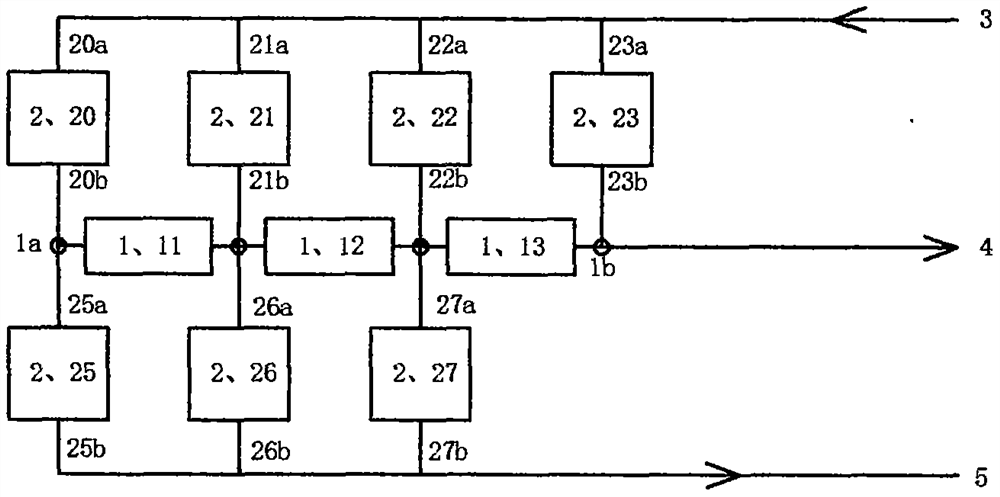

Embodiment 1

[0038] Example 1. A double-layer rigid pipeline structure of a water purifier with an upper module and a lower gallbladder chamber, including a lower gallbladder chamber with bottom pipelines, and an upper-layer related pipeline that cooperates with the lower gallbladder chamber The double-layer rigid pipeline structure is composed of upper modules; the double-layer rigid pipeline structure is connected in series with the inlet and outlet of the pre-filter, reverse osmosis membrane filter, and subsequent functionalized filter through another water port. The filter channel, the part connected in series with the pre-filter gallbladder is the pre-filter channel; the head and tail of the pre-filter channel are respectively connected to the pre-water inlet pipeline and the pre-water outlet pipeline, and are connected to the booster pump through the pre-water outlet pipeline It is connected to the water inlet of the reverse osmosis membrane filter gallbladder; the lower gallbladder ...

Embodiment 2

[0051] Embodiment 2 On this basis, in the single-layer rigid pipeline structure area enclosed by the front water inlet pipeline, the front recoil pipeline and the electric control valve connection pipeline, two filter gallbladder docking water ports and a front The water inlet and outlet of the filter gallbladder are directly connected; in addition, other filter gallbladder docking nozzles are provided: the other filter gallbladder docking nozzles or the other two filter gallbladder docking nozzles also placed in this area are each directly connected to another pre-filter gallbladder. The water inlet and outlet, or include the two filter gallbladder docking outlets respectively placed inside and outside the area respectively connected to the other pre-filter gallbladder inlet and outlet, or include the two filter gallbladder docking water outlets placed outside the area respectively Dock the inlet and outlet of another pre-filter gallbladder, and then form a core structure conn...

Embodiment 3

[0052] Embodiment 3 On this basis, in the single-layer rigid pipeline structure area enclosed by the pre-inlet pipeline, the pre-recoil pipeline and the electric control valve connection pipeline, two filter gallbladder docking water ports are respectively arranged to connect with the two The relevant nozzles of each pre-filter gallbladder are directly docked, and the filter gallbladder docking nozzles are respectively connected to the nozzles of the docking pre-filter gallbladder outside the area. A core structure and a double-channel single-layer rigid pipeline system with corresponding filter channels and recoil channels are laid out with the core structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com