Corrugated pipe cutting device

A technology for cutting devices and corrugated pipes, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve the problems of insufficient intelligence of the clamping device, insufficient automation of the cutting machine, and low cutting efficiency, and achieve clamping Convenient and fast, simple and reasonable structure, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

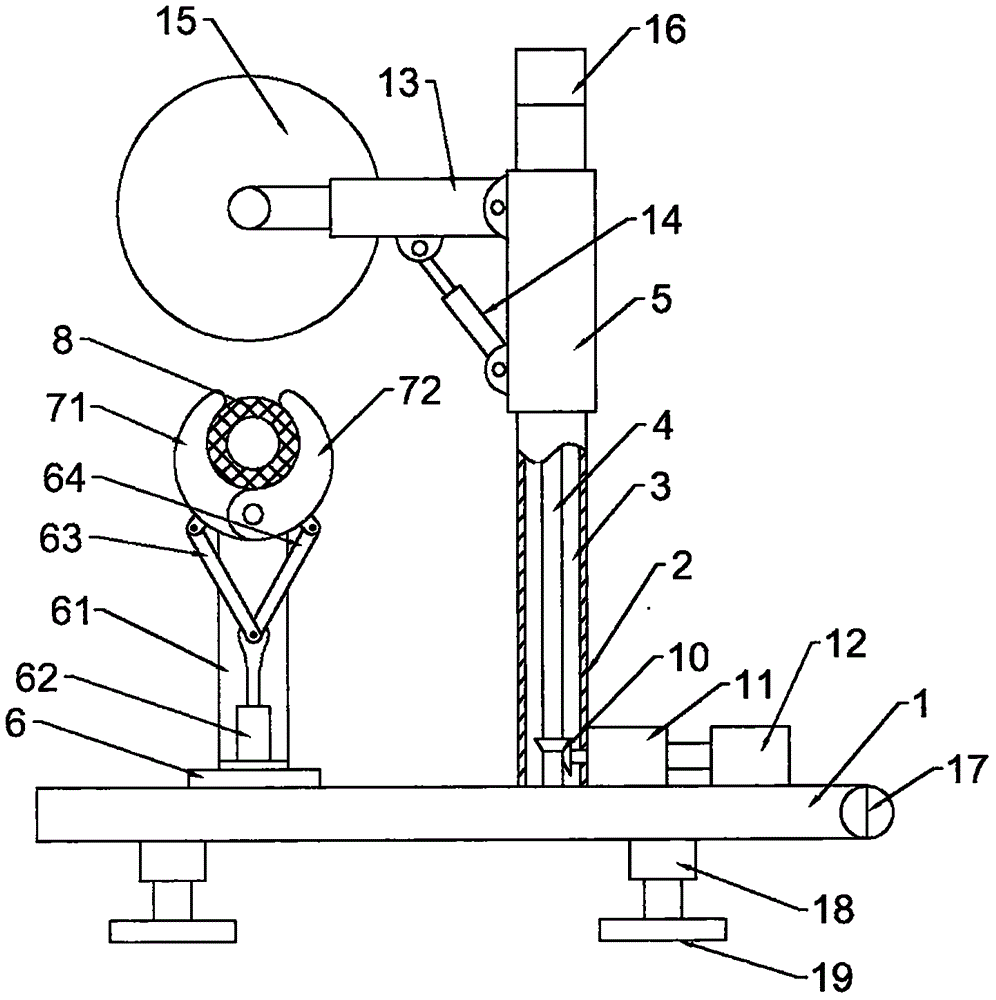

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

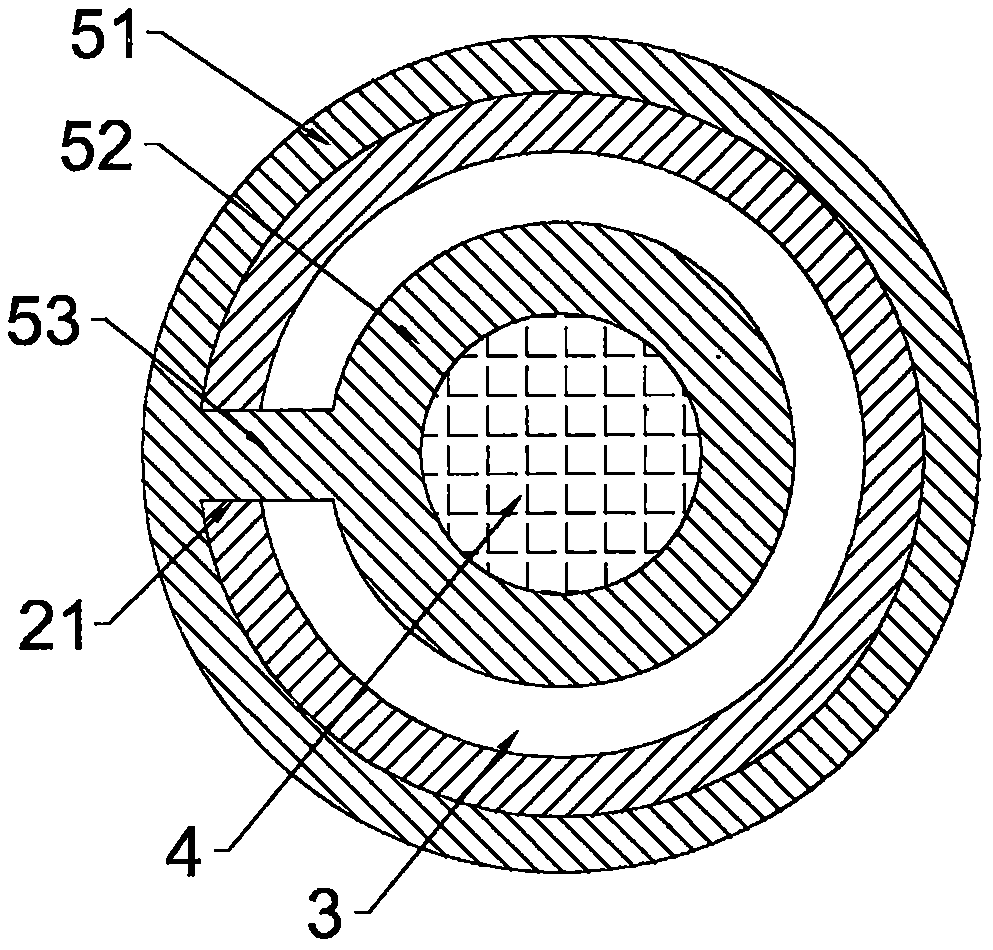

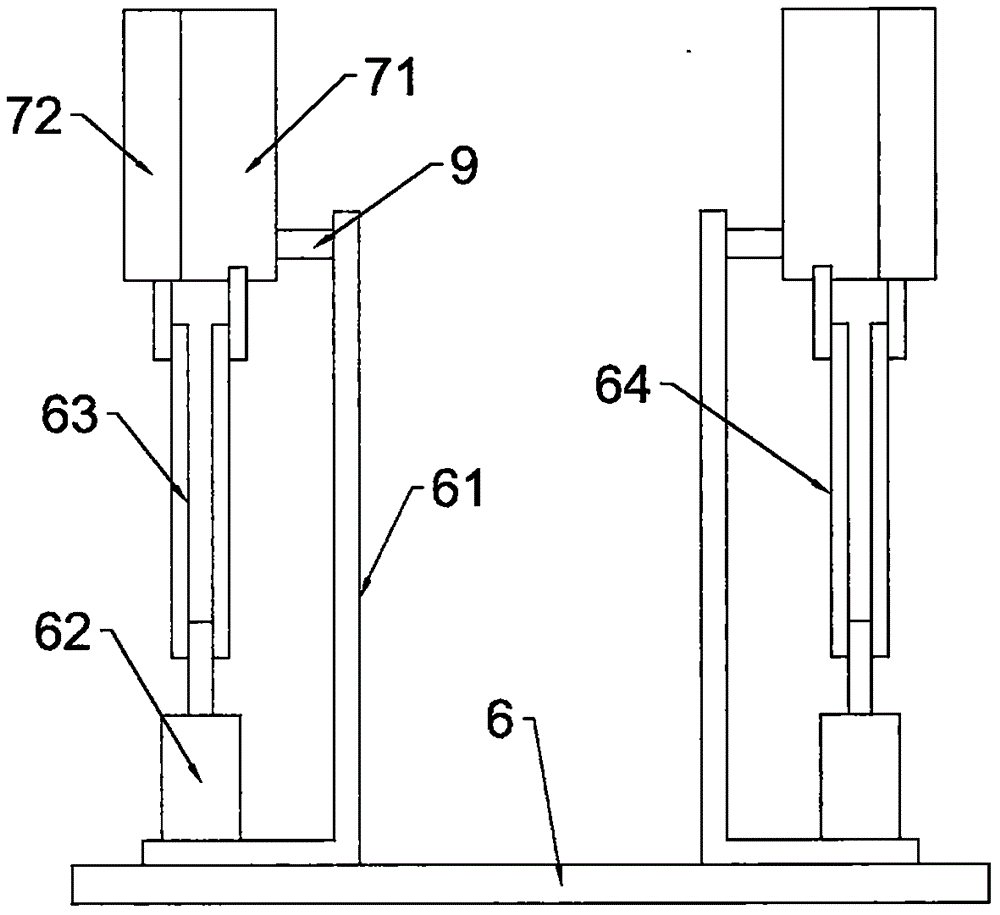

[0017] see Figure 1-3 , a bellows cutting device, comprising a base plate 1, a main support rod 2 is vertically installed on the base plate 1, a sliding sleeve 5 is set on the main support rod 2, a cavity 3 is provided inside the main support rod 2, and the cavity 3 is arranged along the length direction of the main support rod 2, and a screw rod 4 is installed in the cavity 3, and the lower end of the screw rod 4 is installed on the lower part of the main support rod 2 through a bearing (not shown in the figure), and the sliding sleeve 5 includes an outer sleeve 51 and an inner sleeve 52 , the outer cover 51 is connected to the inner cover 52 through the connecting block 53, and the outer cover 51, the inner cover 52 and the connecting block 53 are integrally formed. The support rod 2 is also provided with a sliding hole 21 matched with the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com