Underground continuous wall construction technique of multi-spindle long spiral drill pipe occluding pile

A technology of underground diaphragm wall and construction technology, which is applied in the field of underground diaphragm wall construction technology of multi-axis long auger drill pipe occlusal piles. Solve the problems of low strength of the soil mixing wall, and achieve the effects of being beneficial to management and environmental protection, improving the utilization rate of steel, and reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

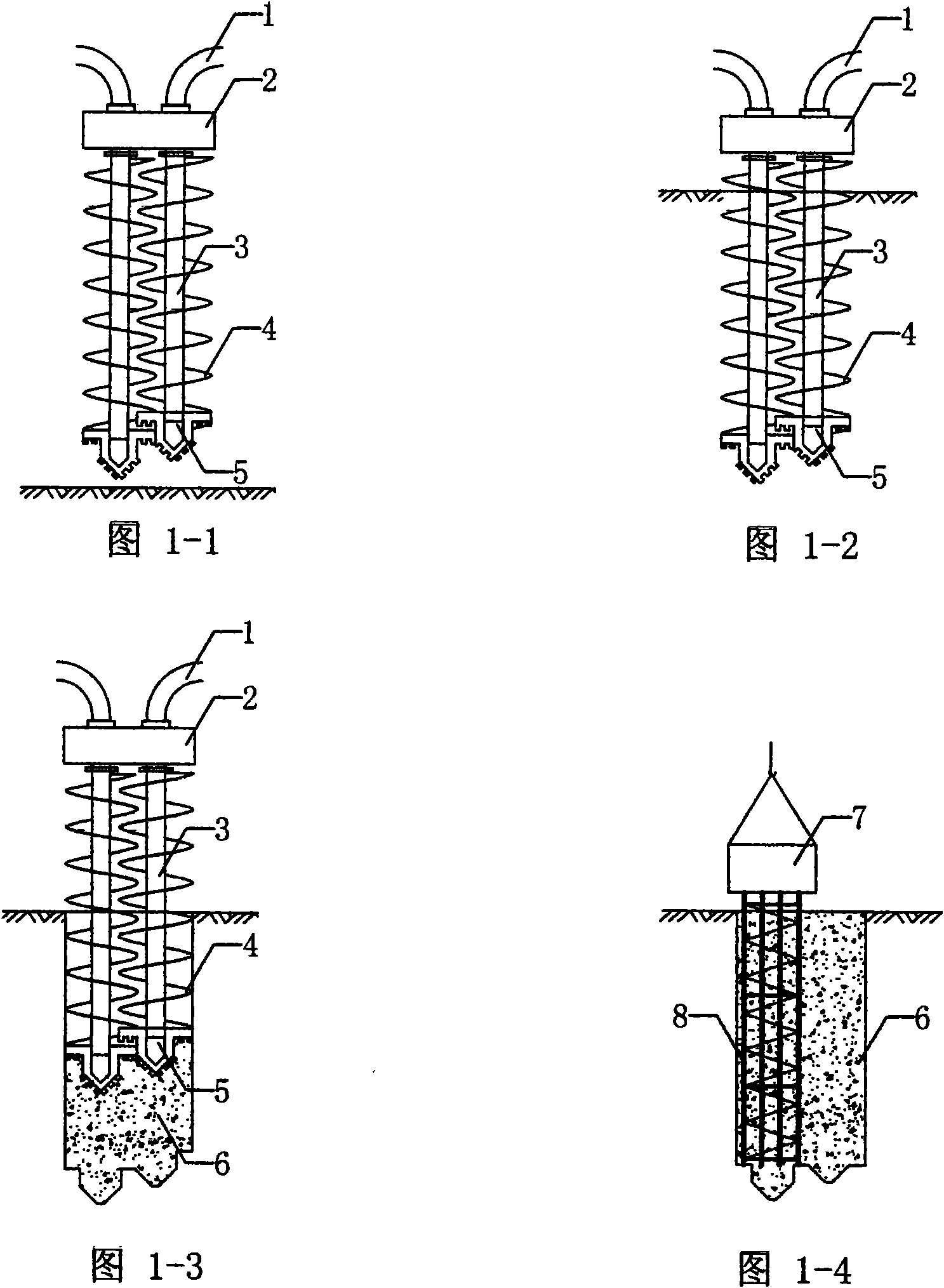

[0026] Embodiment one.( figure 1 )

[0027] According to the design and construction requirements of the underground diaphragm wall, two long auger drill pipes with a diameter of 2m are used to construct a 50m deep pile hole, and the blade engagement degree between the two long auger drill pipes is 800mm. Driven by the driving device, the two long auger drill rods rotate in opposite directions, and the helical direction of the helical blades on the drill rods is also opposite. During the process, the one-way valve set at the front end of the drill pipe is always closed due to pressure. When the drill pipe reaches the depth of 50m, the drilling rig gradually lifts the drill pipe upwards, while pumping the concrete into the hole through two concrete delivery pipes for concrete pouring. At this time, the one-way valve at the end of the rod is affected by Push outward to open, pour concrete into the hole to form concrete piles and bite together to form a concrete underground con...

Embodiment 2

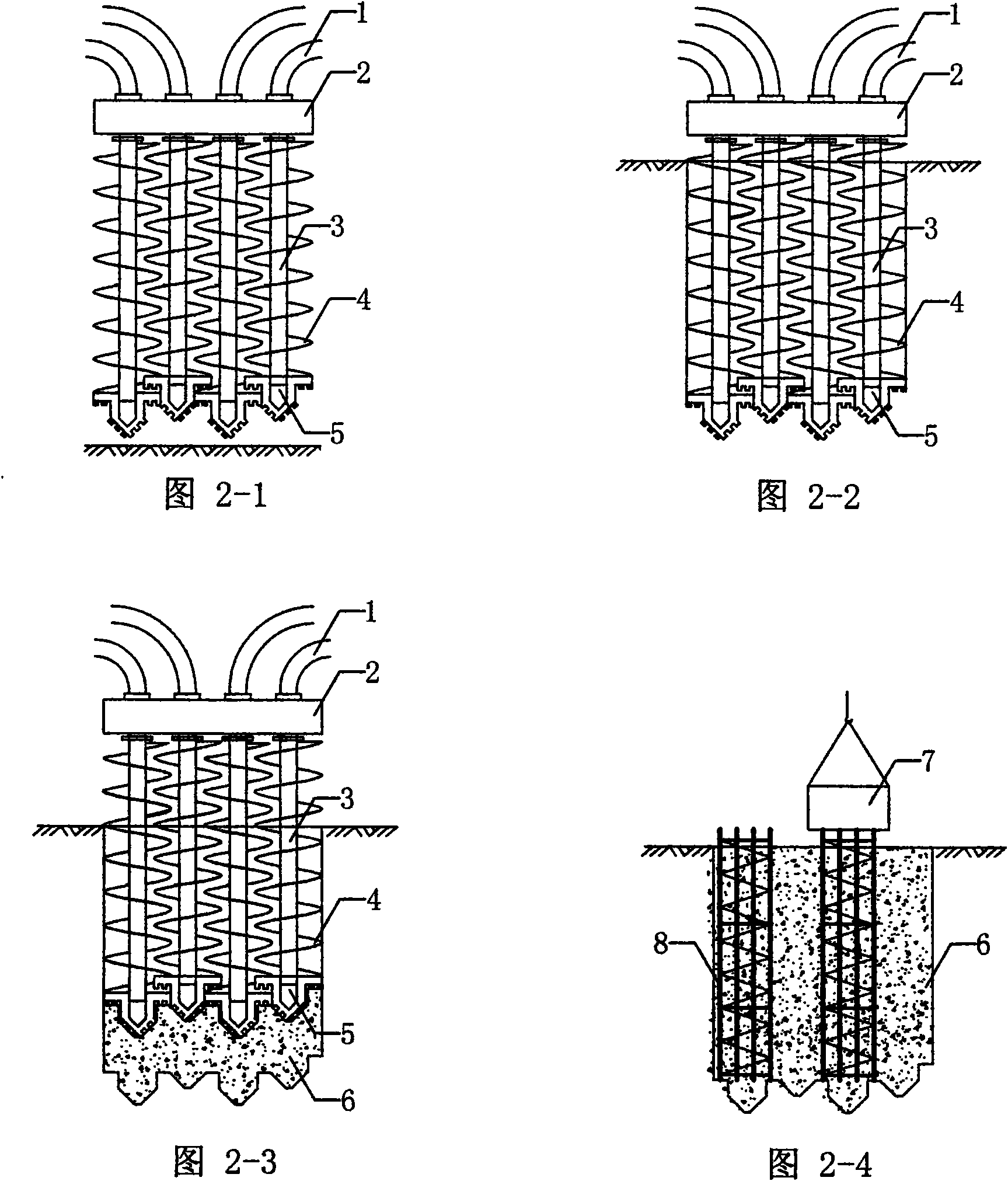

[0028] Embodiment two.( figure 2 )

[0029] According to the design and construction requirements of the deep foundation maintenance wall, 4 long auger drill pipes 3 with a diameter of 0.3m are used for the construction of 10m deep pile holes, and the engagement degree between the blades of the 4 long auger drill pipes 3 is 100mm. 4 long helical drill rods 3 are driven by the driving device 2, and the 4 long helical drill rods 3 rotate in opposite directions. During the drilling process, the one-way valve arranged at the front end of the drill pipe is always closed due to pressure. When the drill pipe reaches the depth of 10m, the drilling rig gradually lifts the drill pipe upwards, while pumping the concrete through the concrete delivery pipes of the four drill pipes to the hole for concrete pouring. At this time, the unidirectional The valve is opened due to the outward thrust, and the concrete pile is poured into the hole and snapped together. When the drill pipe is pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Drilling depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com