Rapid drilling device for hardware production

A drilling device and hardware technology, which is applied in the field of fast drilling devices for hardware production, can solve the problems of affecting the appearance, inaccurate drilling, easy shaking, etc., and achieve the effect of high drilling efficiency and fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

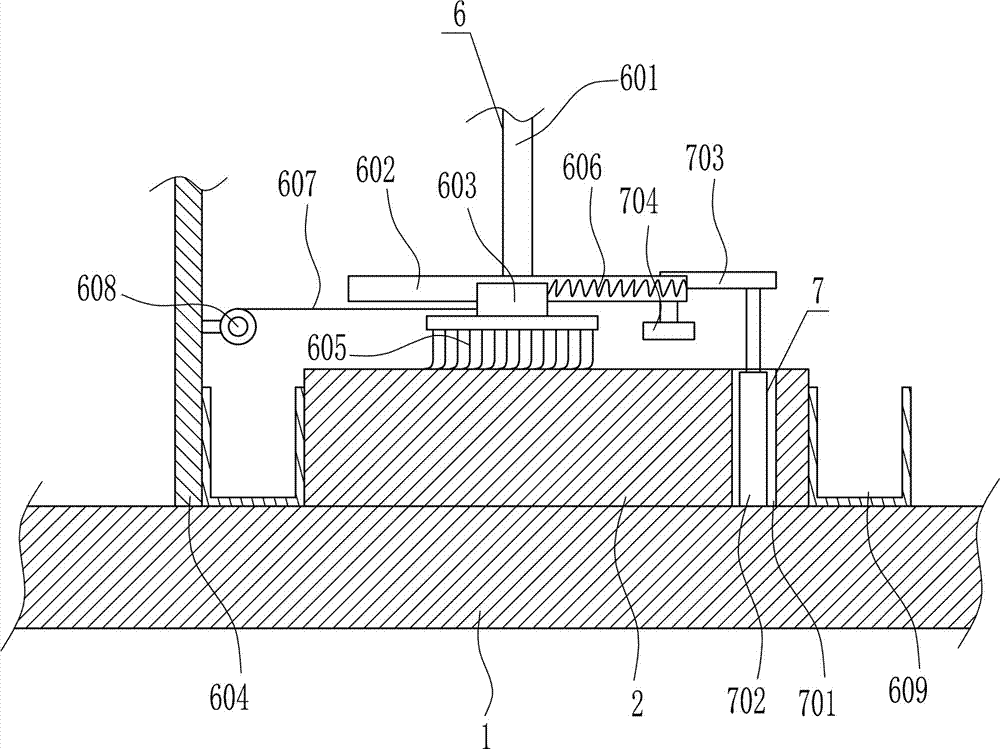

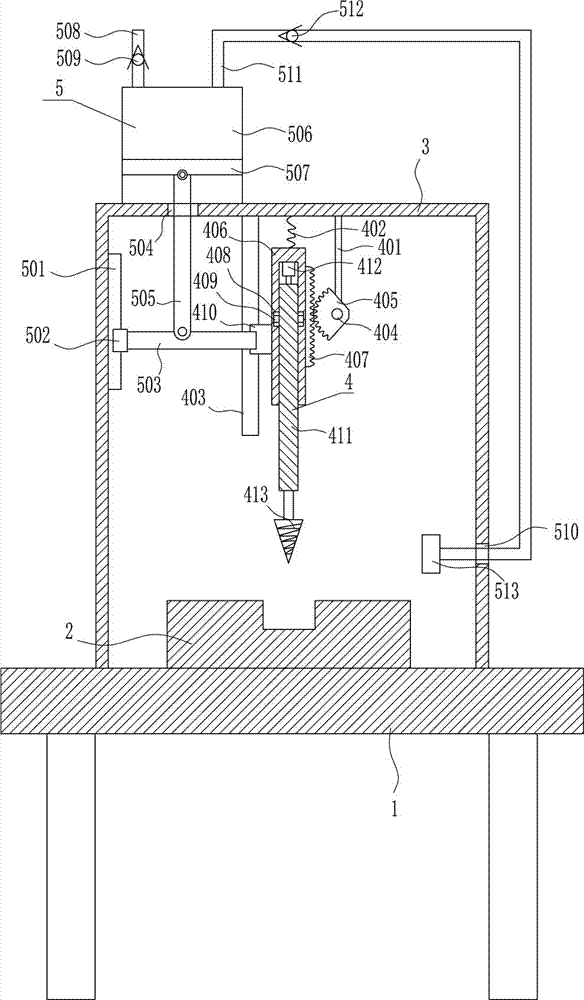

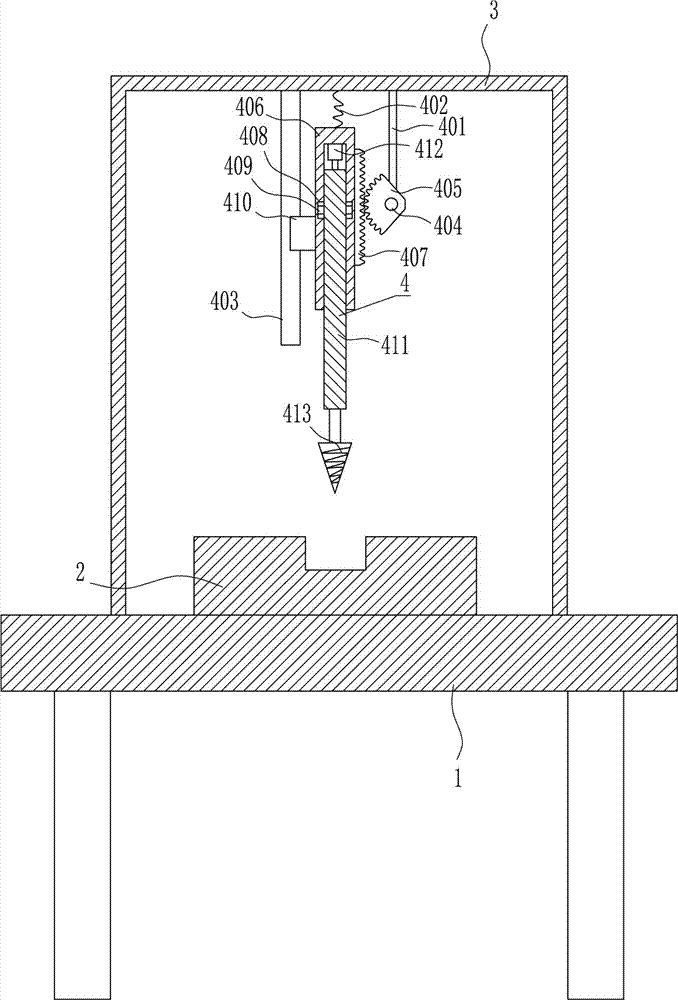

[0037] A fast drilling device for hardware production, such as Figure 1-6 As shown, it includes a workbench 1, a U-shaped placing block 2, an n-shaped plate 3 and a drilling device 4. The top of the workbench 1 is welded with an n-shaped plate 3 and a U-shaped placing block 2, and the U-shaped placing block 2 is located on the n-shaped Inside the plate 3, a drilling device 4 is provided on the inner top of the n-type plate 3.

Embodiment 2

[0039] A fast drilling device for hardware production, such as Figure 1-6 As shown, it includes a workbench 1, a U-shaped placing block 2, an n-shaped plate 3 and a drilling device 4. The top of the workbench 1 is welded with an n-shaped plate 3 and a U-shaped placing block 2, and the U-shaped placing block 2 is located on the n-shaped Inside the plate 3, a drilling device 4 is provided on the inner top of the n-type plate 3.

[0040] The drilling device 4 includes a first pole 401, a first spring 402, a first slide rail 403, a first motor 404, a sector gear 405, an outer telescopic post 406, a rack 407, a first slide block 409, a second slide The block 410, the inner telescopic column 411, the second motor 412 and the drill bit 413, the first support rod 401, the first spring 402 and the first slide rail 403 are connected with the inner top of the n-type plate 3 sequentially from right to left, and the first support rod The bottom end of 401 is connected with the first moto...

Embodiment 3

[0042] A fast drilling device for hardware production, such as Figure 1-6 As shown, it includes a workbench 1, a U-shaped placing block 2, an n-shaped plate 3 and a drilling device 4. The top of the workbench 1 is welded with an n-shaped plate 3 and a U-shaped placing block 2, and the U-shaped placing block 2 is located on the n-shaped Inside the plate 3, a drilling device 4 is provided on the inner top of the n-type plate 3.

[0043] The drilling device 4 includes a first pole 401, a first spring 402, a first slide rail 403, a first motor 404, a sector gear 405, an outer telescopic post 406, a rack 407, a first slide block 409, a second slide The block 410, the inner telescopic column 411, the second motor 412 and the drill bit 413, the first support rod 401, the first spring 402 and the first slide rail 403 are connected with the inner top of the n-type plate 3 sequentially from right to left, and the first support rod The bottom end of 401 is connected with the first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com