Drilling equipment for bearing

A drilling equipment and bearing technology, applied in the field of bearing processing, can solve the problems of low degree of automation, slow drilling speed, low work efficiency, etc., and achieve the effects of high work efficiency, easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

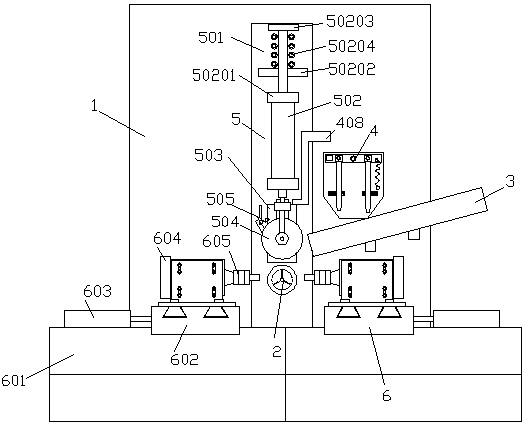

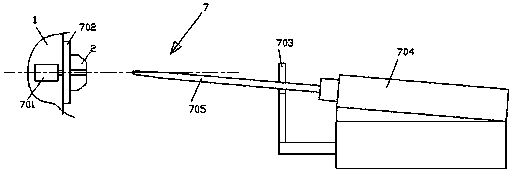

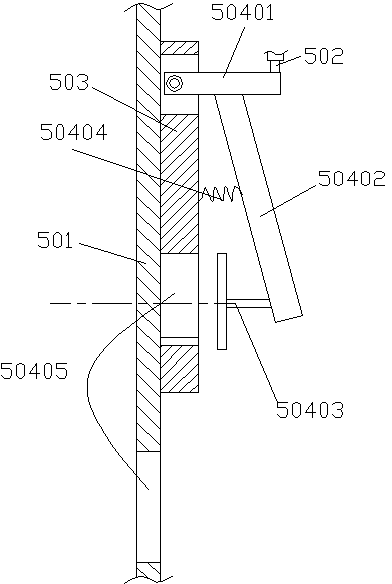

[0039] Examples, see attached figure 1 , 2, 3, 4, 5, drilling equipment for bearings, including machine tool body 1, tensioning spindle 2 installed on machine tool body 1, machine tool body including bed, electrical control part, transmission part, tensioning spindle control part etc., the tensioning spindle 2 can be radially expanded and retracted to realize the tensioning and fixing of the ferrule. When it is placed for drilling, the ferrule will rotate or move axially. The structure it adopts can be similar to three The jaw chuck can be controlled by pneumatic control, electric control or mechanical transmission. When it is opened, the outer circular surface forms an opening, because the main body of the machine tool and the tensioning spindle are well-known technologies in the art, and will not be described in detail here.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com