Furniture sponge drilling machine

A drilling machine and sponge technology, applied in metal processing and other directions, can solve the problems of affecting the use effect, deformation, and unable to control the direction of shrinkage, etc., to achieve high work efficiency, good effect, and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

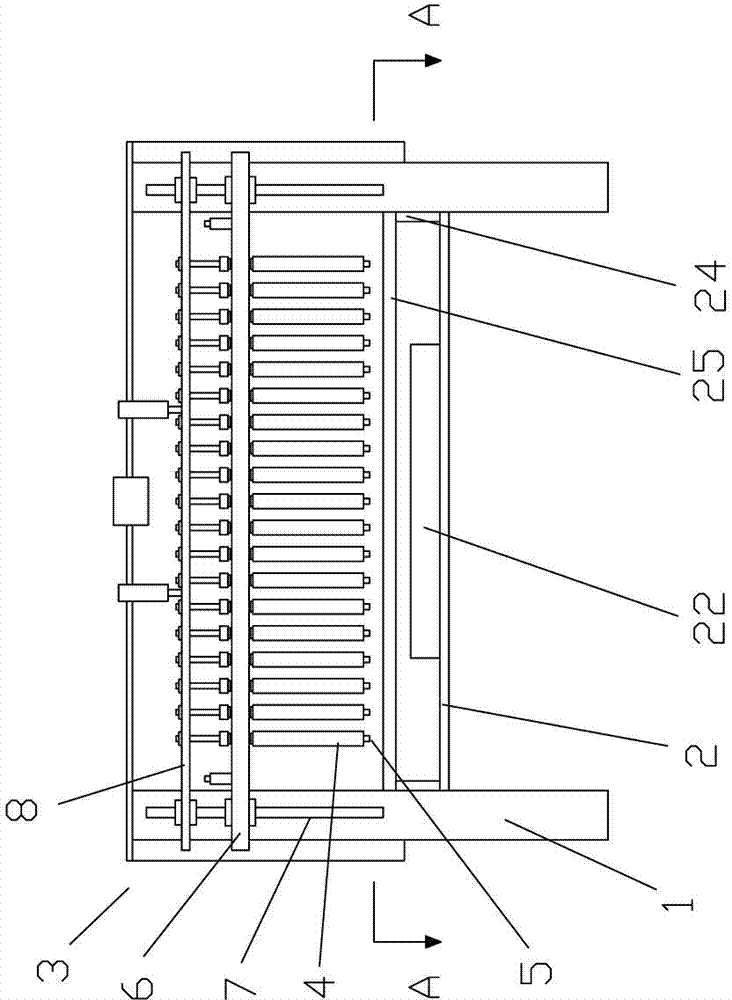

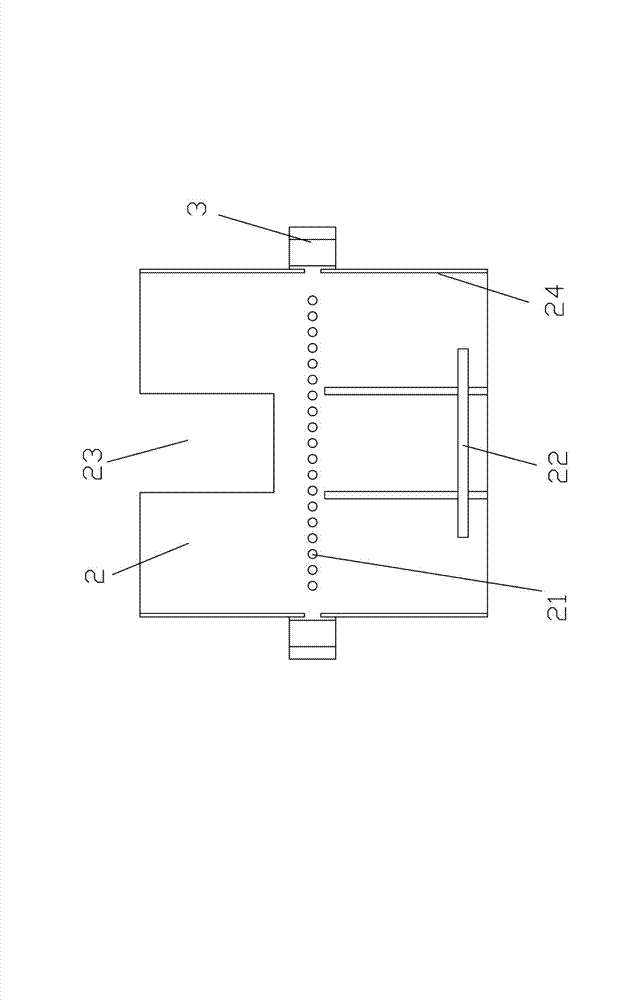

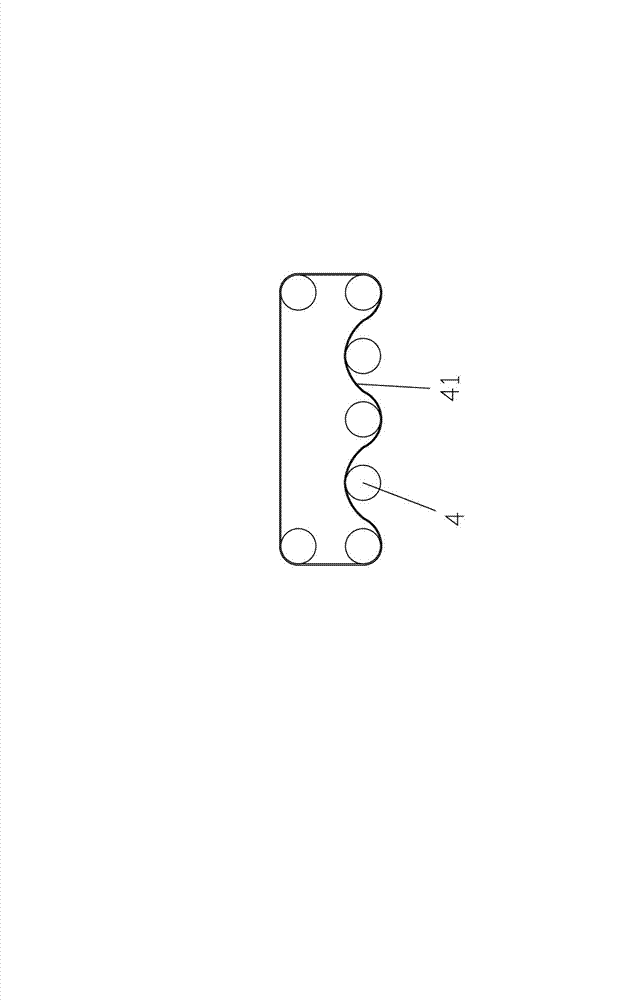

[0019] refer to figure 1 , figure 2 , image 3 , a furniture sponge drilling machine with good drilling effect, convenient use and high work efficiency provided by the present invention comprises a frame 1, and the frame 1 is provided with a workbench 2 for placing furniture sponges, and the workbench The middle part of 2 is provided with a gantry support 3, and a plurality of hollow drill bits 4 that can move up and down are horizontally arranged on the gantry support 3, and the rotation directions of two adjacent hollow drill bits 4 are opposite, so that the contact between the adjacent two hollow drill bits and the furniture sponge The direction of force on the surface is opposite, and the force on the entire furniture sponge reaches a balanced state, which avoids deformation of the furniture sponge and ensures the drilling effect. Each hollow drill bit 4 is provided with a push rod 5 that can move up and down. When the hollow drill bit 4 is drilling, the push rod 5 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com