A variable diameter stabilizer

A stabilizer and variable technology, applied in drilling equipment, earthmoving, drill pipe, etc., can solve the problems of reducing drilling aging, wellbore instability, scraping the well wall, etc., to improve drilling aging, easy operation, The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

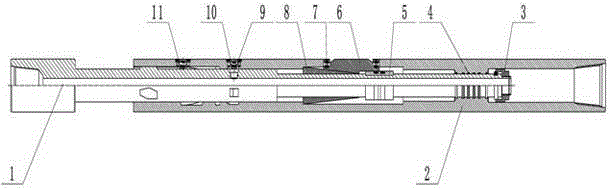

[0021] The invention belongs to the field of drilling, and relates to a variable-diameter stabilizer suitable for drilling operations, which is generally installed behind a screw drilling tool and in front of a MWD instrument.

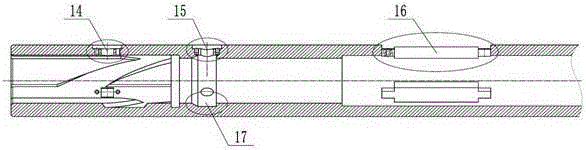

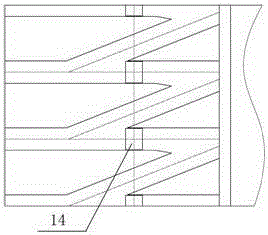

[0022] see Figure 1 to Figure 4 , the specific structure of a variable-diameter stabilizer related to the present invention is as follows: it includes a housing 2, a central tube 1 is arranged in the housing 2, a taper sleeve 8 is set on the outer diameter of the central tube 1, and a set is installed under the taper sleeve 8. The retaining ring 5 on the center tube 1 is used to push the taper sleeve 8 to move up when the center tube 1 moves upward (to the left in the figure). The stabilizing block 6 is set on the housing 2, and the two ends of the stabilizing block 6 are provided with a return position. The spring 7, the stabilizing block 6 and the tapered sleeve 8 are in contact; the outer diameter of the central tube 1 is uniformly distributed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com