An all-electric coal mine tunnel drilling rig

A tunnel drilling rig, all-electric technology, used in rotary drilling rigs, earth-moving drilling, drilling equipment, etc., can solve problems such as high safety hazards, inability to achieve stepless speed regulation, and low energy utilization, and reduce oil quality. requirements, improve fault self-diagnosis, and improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

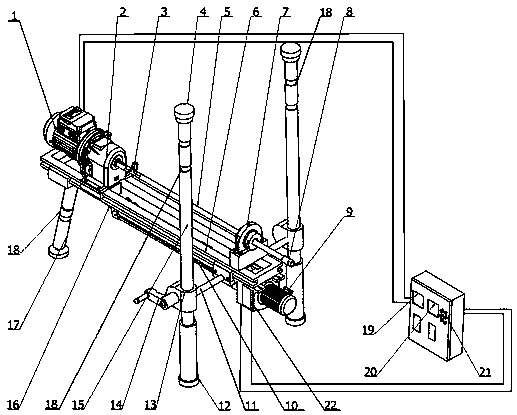

[0025] The invention includes a slewing mechanism, a feeding mechanism, a lifting and angle-changing mechanism and a control system;

[0026] The slewing mechanism is composed of a slewing motor 1, a cycloidal pinwheel reducer 2, a faucet 3, a drill rod 5, a carriage 6, a centralizer 7 and a drill bit 8, and the slewing motor 1 is decelerated by the flange and the cycloidal pinwheel. The drill rod 5 is connected with the cycloid reducer 2, and the cycloid reducer 2 is installed on the carriage 6, and can slide left and right on the carriage 6; the faucet 3 is installed on the cycloid reducer 2 On the drill pipe 5 at the right end; the centralizer 7 is fixed on the carriage 6, the drill pipe 5 is set up and limited by the centralizer 7, and the drill bit 8 is connected to the drill pipe 5 by threads;

[0027] The feed mechanism includes a feed motor 9, a feed cylinder 10 and a piston rod 16, the feed motor 9 is fixed on the carriage 6, the support shaft 11 is hinged with the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com