A variable-diameter stabilizer that can be controlled on the ground

A stabilizer and ground technology, applied to drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of reducing drilling time efficiency, scraping, long adjustment period, etc., and achieve improved drilling time efficiency, simple device structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

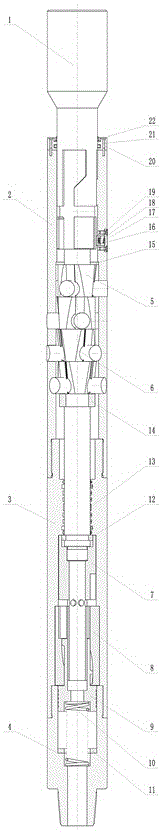

[0041] This embodiment provides a variable diameter stabilizer that can be controlled on the ground, such as Figures 1 to 5 As shown, it includes a tubular casing, the casing is equipped with a central shaft 1, and the casing is composed of an upper casing 2, a middle casing 3 and a lower casing 4 connected in sequence,

[0042] The upper part of the central shaft 1 is provided with a self-locking groove, and the middle part of the central shaft 1 is fixed with a tapered sleeve 5;

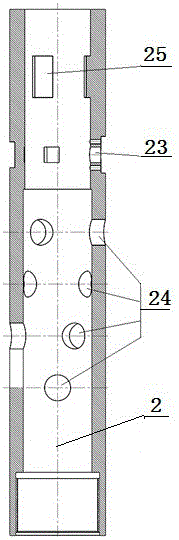

[0043] The upper part of the upper housing 2 is provided with a lock block square hole 23, and a self-locking device is installed in the lock block square hole 23. The inner end of the self-locking device corresponds to the self-locking groove on the central axis 1; the lower part of the upper housing 2 is along the circumferential direction There are a plurality of cylindrical holes 24 distributed in the axial direction. The cylindrical holes 24 are equipped with stabilizing columns 6 , and the i...

Embodiment 2

[0049] On the basis of Embodiment 1, the self-locking device in the lock block square hole 23 in this embodiment is made up of a self-lock block 16, a self-lock spring 17, a spring pressing plate 18 and a fastening screw 19, and the fastening screw 19 presses the spring pressing plate 18 is fixed in the square hole 23 of the locking block, the self-locking spring 17 and the self-locking block 16 are positioned at the inner side of the spring pressing plate 18, and the two ends of the self-locking spring 17 are respectively fixed on the spring pressing plate 18 and the self-locking block 16, and the self-locking block 16 The bottom end face is arc-shaped, such as Figure 11As shown, the self-locking block 16 is a cube structure, one end face is arc-shaped, one corner of the arc-shaped end face is cut off, and the other end face is provided with a cylindrical spring hole for installing the self-locking spring 17 .

[0050] A rectangular protrusion 25 is also provided on the inne...

Embodiment 3

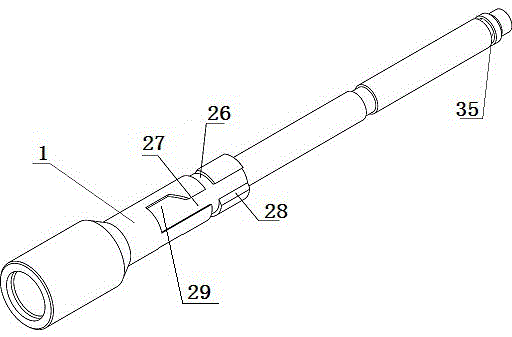

[0056] In Embodiment 1, the stabilizing post 6 will move radially along with the axial movement of the tapered sleeve 5. In this embodiment, as Image 6 with Figure 7 As shown, the upper end surface of the stabilizing column 6 is an arc surface, and the lower end surface is a conical plane with a dovetail groove 30 .

[0057] In this embodiment, the dovetail groove 30 and the dovetail block track 31 are used to cooperate to connect the stabilizing post 6 to the tapered sleeve 5. With the axial movement of the tapered sleeve 5, the stabilizing post 6 moves on the tapered surface. The dovetail block track 31 on the sleeve 5 slides and moves radially.

[0058] In this embodiment, the tapered sleeve 5 may also be spliced by several tapered sleeves fitted on the central shaft 1 sequentially in the axial direction.

[0059] Further, the plurality of cylindrical holes 24 are distributed in a helical shape along the axial direction at the lower part of the upper casing 2 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com