Variable-diameter stabilizer

A stabilizer and variable technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve problems such as increased risk of collapse, long operation cycle, stuck pipe, etc., to reduce the risk of collapse, save tripping time, reduce Effect of Soaking Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

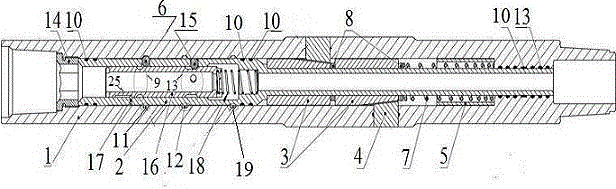

[0033] This embodiment provides a variable-diameter stabilizer, including a cylindrical housing 1, the inner wall of the housing 1 is provided with at least a first housing lock ring groove 11, a second housing lock ring groove 11, and a second housing lock ring groove from top to bottom. The ring groove 19 is two shell lock ring grooves, the housing 1 is provided with a piston 2, the piston 2 is a hollow structure, the upper end of the piston 2 is provided with a pressure cap 14, and the upper part of the piston 2 is provided with a A sliding sleeve 16 that can move axially along the piston 2. The outer surface of the piston 2 is provided with a card shaft 17, a first lock shaft 6, and a second lock shaft 15 in sequence from top to bottom. The first lock shaft 6, the second lock shaft The two locks 15 are multiple and evenly distributed in the circumferential direction. The outer surface of the lower part of the piston 2 is provided with a plurality of conical sleeves 3 from t...

Embodiment 2

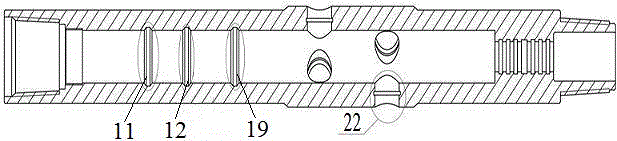

[0040] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the shown variable diameter stabilizer, the inner wall of the housing 1 is provided with a first housing lock ring groove 11, a third housing lock ring groove 12, and a second housing lock ring groove from top to bottom. 19. The lock ring groove 11 of the first housing, the lock ring groove 12 of the third housing and the lock ring groove 9 of the first sliding sleeve are all matched with the first lock ring 6, and the lock ring groove of the second housing is Both the ring groove 19 and the ring groove 13 of the second sliding sleeve lock are matched with the second lock 15;

[0041] The first sliding sleeve lock ring groove 9, the first lock ring groove 6, the first housing lock ring groove 11, the third housing lock ring groove 12, the second sliding sleeve lock ring groove 13, the second The distances between the lock shaft 15 , the second housing lock shaft ring groove 19 and the top of t...

Embodiment 3

[0047] On the basis of Embodiment 2, this embodiment provides a variable-diameter stabilizer, the piston 2 is a hollow structure with a large inner diameter and a small bottom, and the lower part of the piston 2 is sleeved with a plurality of tapered sleeves 3 Smaller inner diameter. Both ends of the large diameter part are provided with seals 10, and the structure of the piston 2 is as follows: image 3 shown.

[0048] One end of the sliding sleeve 16 is provided with a Kashaw groove 25 , and the other end is provided with a discharge hole 27 and a ball-throwing blocking shoulder 26 sequentially from top to bottom. The liquid flow channel of the sliding sleeve 16 is opened, and the liquid flows out through the discharge hole 27 .

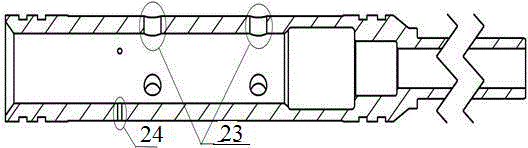

[0049] Such as Image 6 As shown, the centralizing column 4 is columnar, one end surface is a cylindrical surface, and the other end is a conical plane matched with the conical surface of the conical surface sleeve 3. The conical surface is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com