A pulse shock frequency generator

A generator and pulse technology, which is applied in the field of pulse seismic frequency generators, can solve problems such as lack of understanding, inability to release jams, insufficient shock frequency and intensity, etc., to improve fluid properties, increase drilling time efficiency, and reduce fishing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

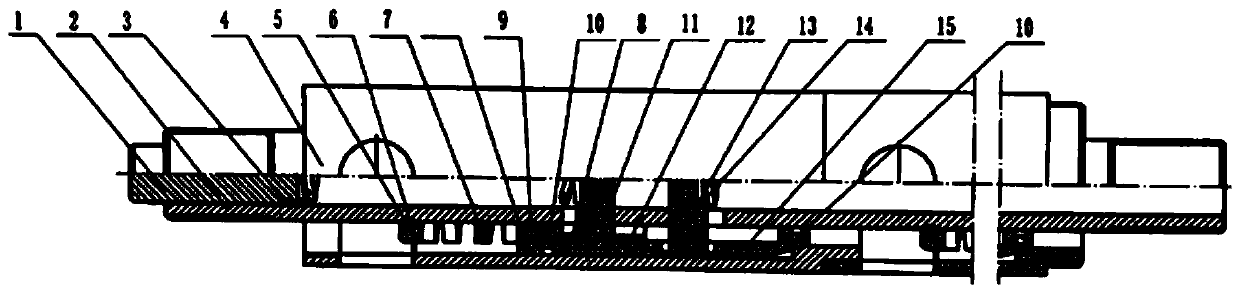

[0029] Such as figure 1 As shown, this embodiment provides a pulse shock frequency generator, which includes: a hydraulic cylinder, a connecting rod, a piston, and a pressure relief valve; the inside of the hydraulic cylinder is provided with a stepped hole with openings at both ends; the ladder The narrow section of the hole is a low-pressure chamber, and the wide section of the stepped hole is a high-pressure chamber; the connecting rod is arranged in the hydraulic cylinder through the stepped hole, and the two ends of the connecting rod are located outside the hydraulic cylinder , the connecting rod is matched with the high-pressure chamber and the low-pressure chamber; the piston and the pressure relief valve are sleeved on the connecting rod and placed in the hydraulic cylinder; the connecting rod is provided with a piston A guide hole and a pressure relief valve guide hole, and the piston guide hole is provided with a piston pin, and the pressure relief valve guide hole ...

Embodiment 2

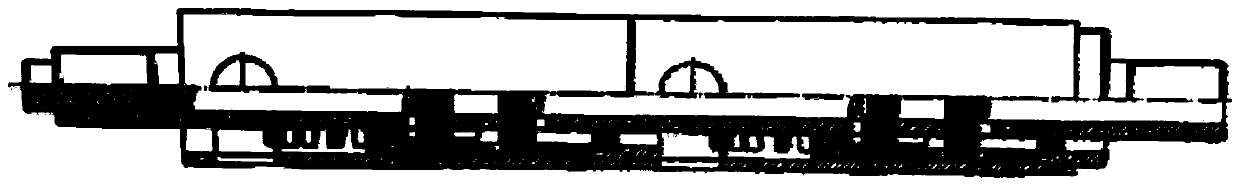

[0042] This embodiment provides a pulse shock frequency generator combined in series with multi-stage hydraulic cylinders, which includes a connecting rod and at least two hydraulic cylinders, and the hydraulic cylinders are all sleeved outside the connecting rod and combined in series; the two connecting rods The ends are respectively located outside the liquid cylinders at both ends, and the high pressure chamber of each liquid cylinder is hung with a piston and a pressure relief valve.

[0043] Specifically, such as figure 2 As shown, the number of hydraulic cylinders is two, namely the first hydraulic cylinder and the second hydraulic cylinder; the first hydraulic cylinder and the second hydraulic cylinder are combined in series and sleeved on the connecting rod, and the two ends of the connecting rod are respectively located at outside the first and second cylinders.

[0044] Wherein, the structure of the first liquid cylinder and the second liquid cylinder is the same ...

Embodiment 3

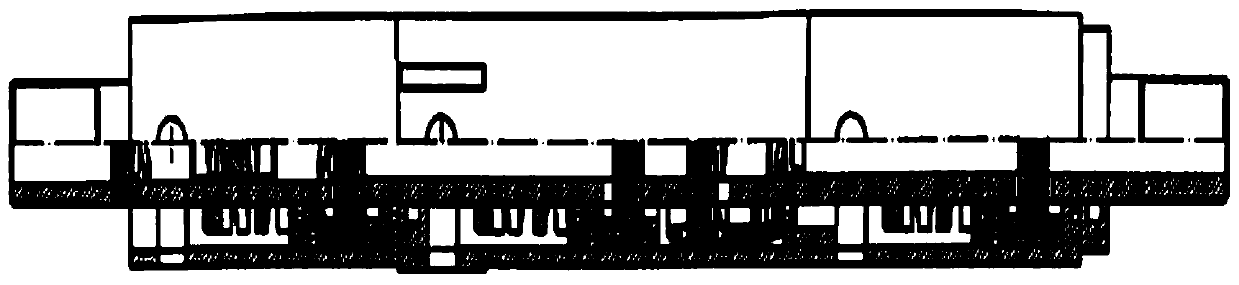

[0046] Such as image 3 As shown, this embodiment provides a pulse vibration frequency generator combined in series with a master cylinder and a slave cylinder, which includes a connecting rod, a first slave cylinder, a master cylinder and a second slave cylinder; the first slave cylinder The cylinder, the master cylinder and the second slave cylinder are sequentially combined in series and sleeved on the connecting rod; the two ends of the connecting rod are located outside the first slave cylinder and the second slave cylinder respectively.

[0047] Wherein, the structure of the first active cylinder is the same as that of the hydraulic cylinder in Embodiment 1, and the first active cylinder is provided with a piston and a pressure relief valve, and the structure and arrangement of the piston and hydraulic valve are the same as those of the piston and pressure relief valve in Embodiment 1. The structure and setting method of the pressure relief valve.

[0048] The inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com