Automatic grouting-type float-collar float-shoe device

A technology of self-grouting and floating hoops, which is applied to wellbore/well valve devices, drilling equipment, wellbore/well components, etc., which can solve problems such as stuck pipe, delayed casing running time, and unbalanced pressure, and achieve improved The effect of improving efficiency, improving drilling timeliness, and balancing internal and external pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

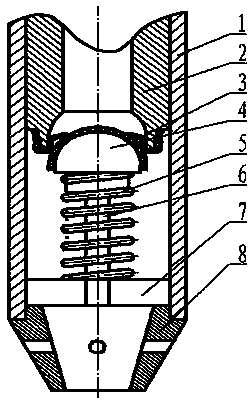

[0011] Such as figure 1 As shown, a self-grouting floating hoop floating shoe device is characterized by a shell 1, a body 2, a clip 3, a sealing hemisphere 4, a spring 5, a central rod 6, a fixing member 7, and a guide shoe 8. Embed four symmetrical clips 3 with a thickness of 8 mm, a width of 5 mm, and two wings of 10 mm on the sealing hemisphere of the one-way valve of the floating shoe, so that there is a gap of about 8 mm between the sealing hemisphere 4 of the one-way valve and the body 2.

[0012] The working principle of the automatic grouting floating hoop floating shoe of the present invention is that during the casing running process, there are four symmetrical ones with a thickness of 8 mm and a width of 5 mm on the sealing hemisphere of the one-way valve of the floating hoop floating shoe with 10 mm two wings. The clamp 3 makes a gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com