Multi-crack fracturing control method for medium-depth coal beds

A multi-fracture, coal seam technology, used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of excessive filtration of fracturing fluid, failure to achieve stimulation effect, and small scale of sand addition, and reduce Construction pressure, improve the success rate of fracturing construction, and ensure the effect of smooth joining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

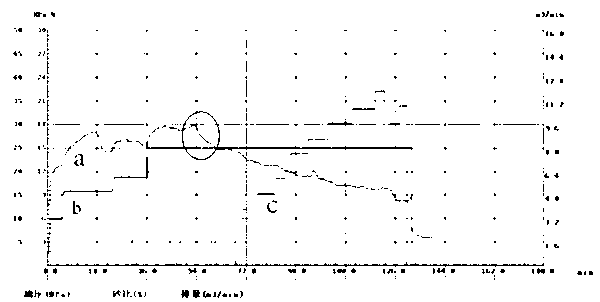

[0023] Such as figure 1 As shown, the medium-deep coal seam controlled multi-fracture fracturing method at least includes:

[0024] 1) Prepare fluid loss fracturing fluid;

[0025] 2) Use a high-pressure pump set to inject the viscous fluid loss fracturing fluid into the formation at high speed, and create fractures in the set layer of the medium-deep coal seam; use a high-pressure pump set to inject the viscous fluid loss fracturing fluid into the formation at high speed, In the middle-deep coal seam setting seam fracture, the pressure of the high-pressure pump set is stepped up.

[0026] 3) Use a high-pressure pump set to inject viscous fluid loss fracturing fluid into the fracture at high speed, and extend the formed fracture inward. In order to prevent the fracture from reclosing under the gravity of the upper rock formation after the pump is stopped, the Add proppant to the injected fluid loss fracturing fluid, so that the proppant is filled in the fractures opened to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com