Automatic turnplate type glue preparation and injection machine

A glue injection machine and turntable-type technology, applied in the field of glue injection machines, can solve problems such as low efficiency, high human uncertainties, and reduced manpower, so as to avoid clogging, improve single injection efficiency, and avoid material dripping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

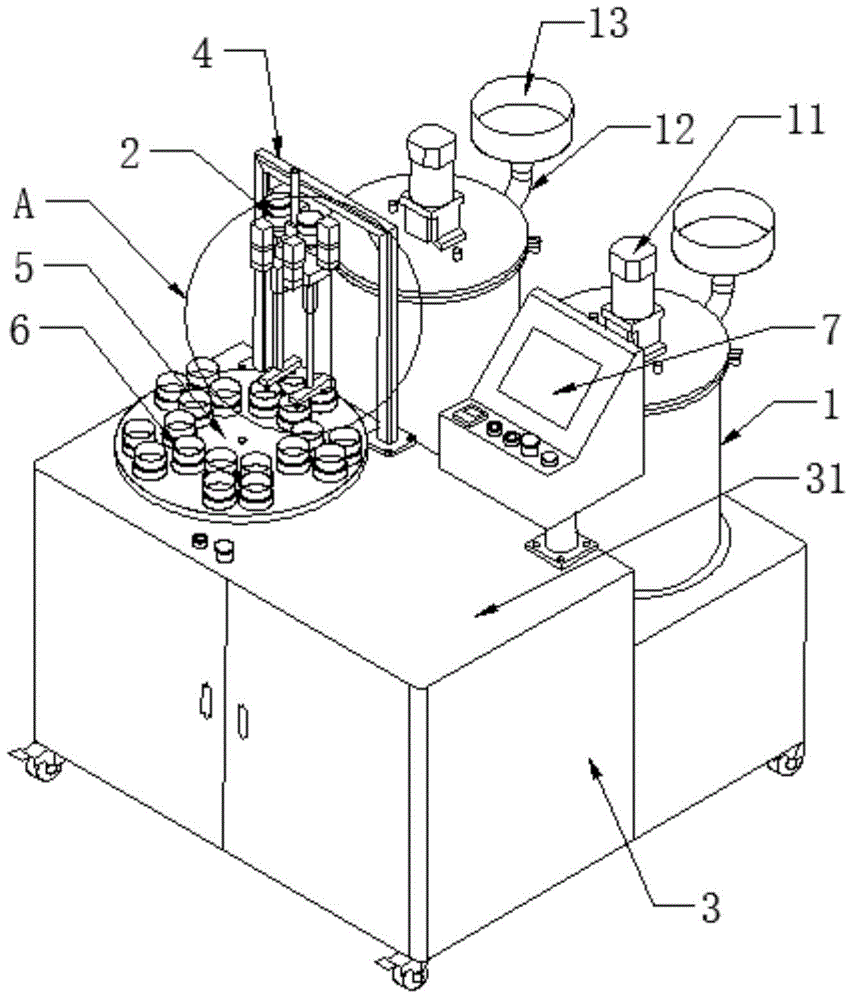

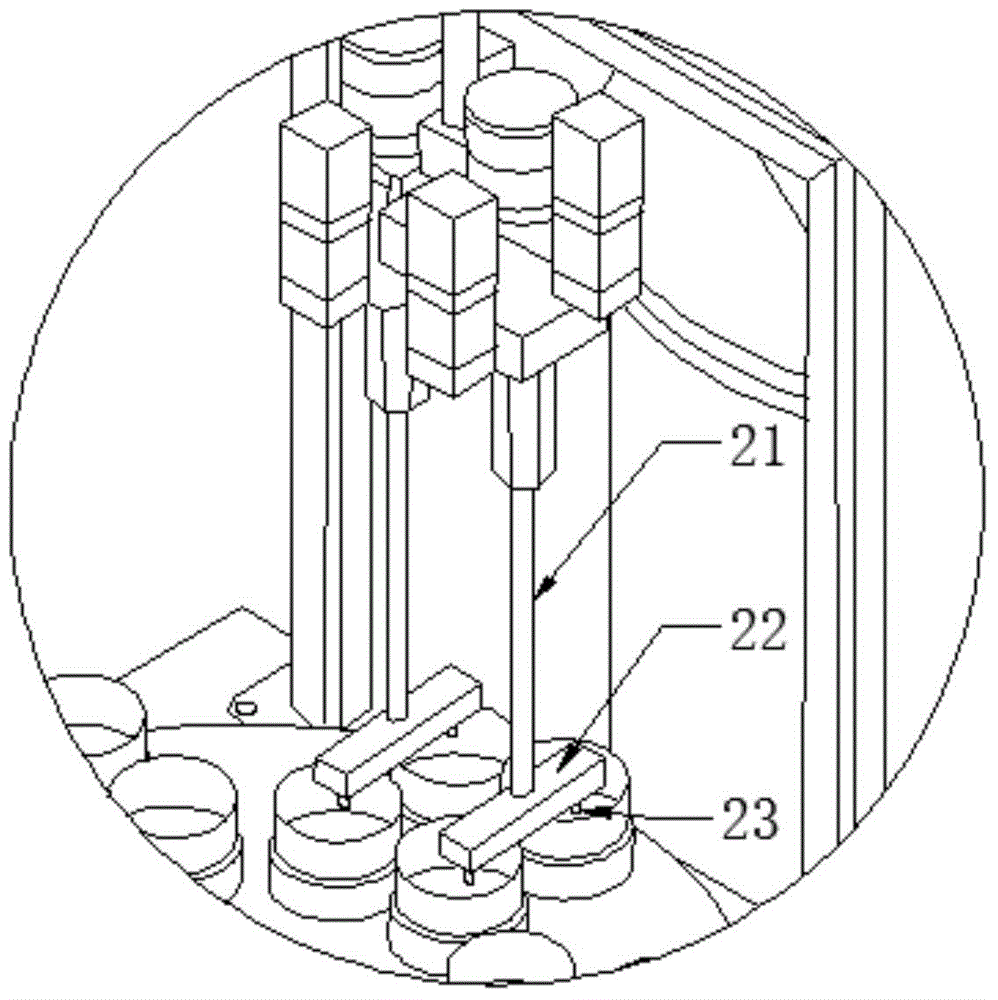

[0020] Embodiment: a kind of rotary disc type automatic dispensing glue injection machine, such as figure 1 As shown, the glue injection machine has at least two barrels 1 and at least one dynamic mixing head 2, the barrel is fixed on the fuselage 3 of the glue injection machine, and the upper body of the glue injection machine is provided with Fixed bracket 4, the dynamic mixing glue filling head is fixed on the fixed bracket, the dynamic mixing glue filling head has a plurality of feed ports and a discharge port, and the number of the feed ports is consistent with the number of barrels , the barrel and the feeding port are communicated one-to-one through the feeding pipe, and each feeding pipe is provided with a metering pump and a feeding valve. The fuselage of the glue injection machine has a working surface 31, and the working surface There is a working turntable 5 on the top. There is a rotating shaft below the working turntable. The upper end of the rotating shaft is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com