Dry hot rock geothermal exploitation method

A mining method, hot dry rock technology, applied in the fields of fluid mining, geothermal energy power generation, earth drilling and mining, etc., can solve the problems of artificial heat storage in areas where hot dry rock cannot be built, and achieve low cost and difficulty, low construction pressure, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

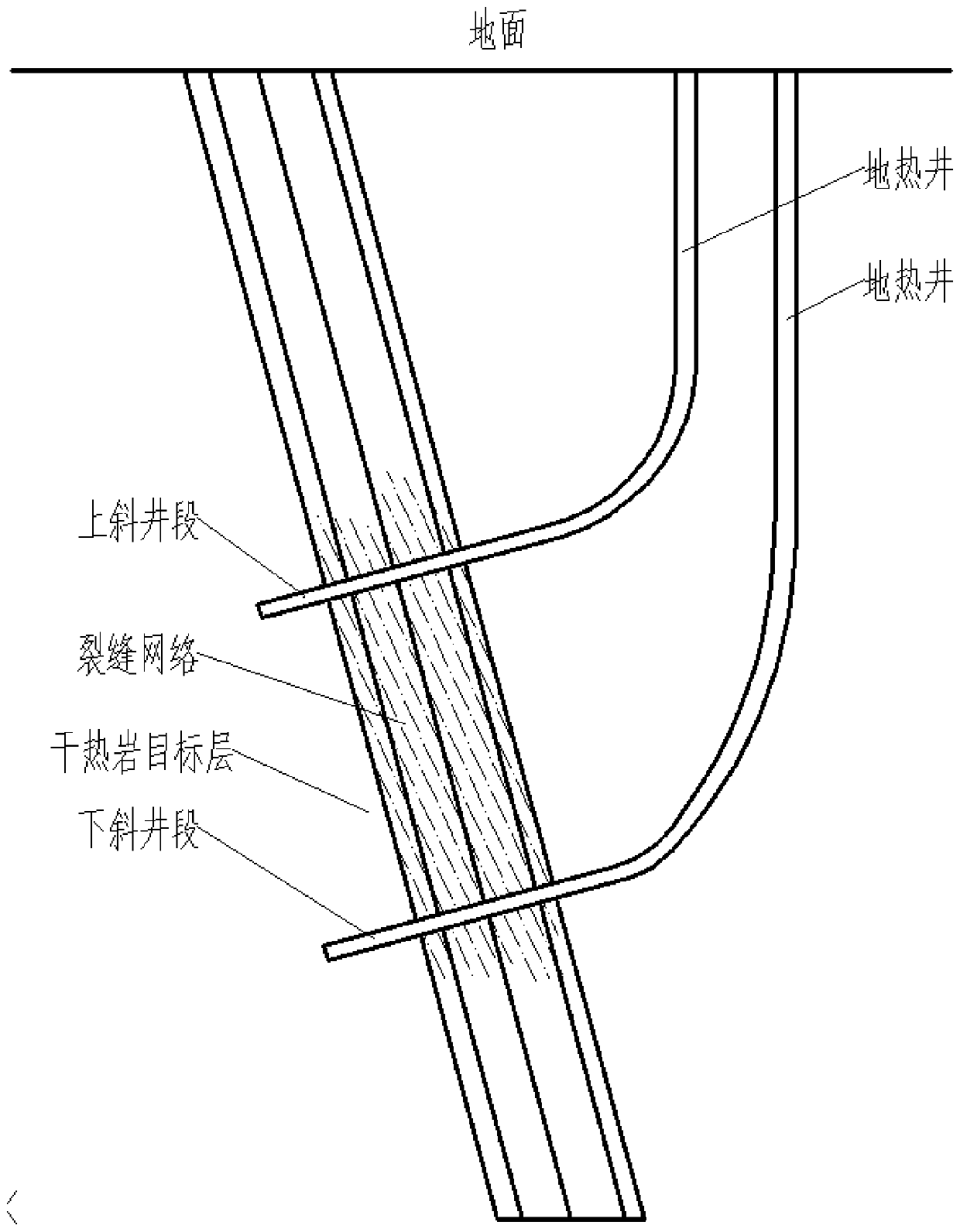

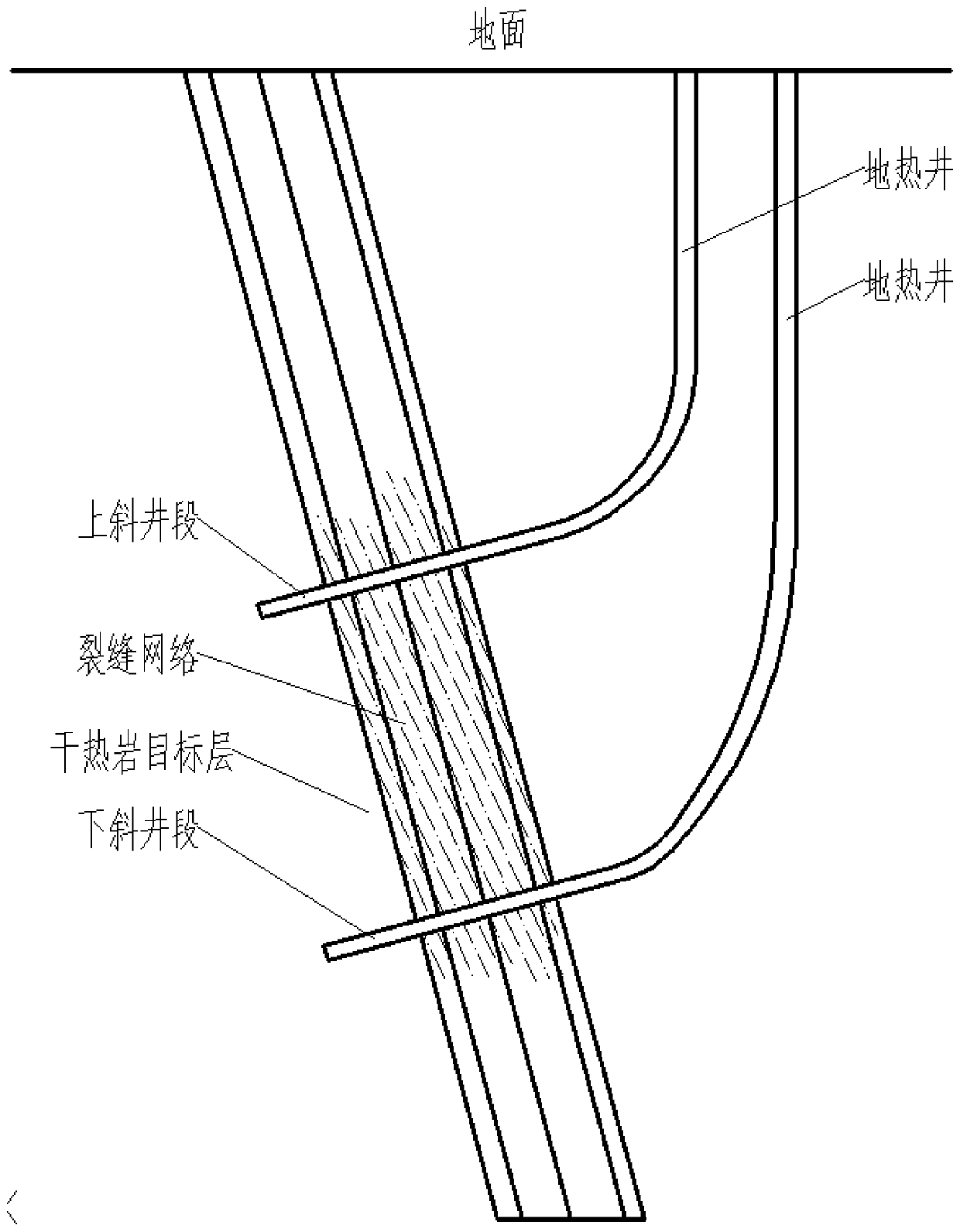

[0021] A geothermal mining method of hot dry rock, which is carried out in the following steps:

[0022] Step 1. Select the target layer, the target layer is 5.5km deep, mainly composed of granite, with a temperature of 200-230°C and a dip angle of 31°;

[0023] Drill two geothermal wells from the ground to the target layer, and the two geothermal wells are inclined to form inclined well sections in the target layer respectively, and the inclination angle of the inclined well sections is 60°, and the inclined well sections and the target Layers are vertical, and the inclined well sections of the two geothermal wells are distributed up and down in the target layer to form an upwardly inclined well section and a downwardly inclined well section, and the horizontal distance between the upwardly inclined well section and the downwardly inclined well section is 20m;

[0024] Step 2. Inject water at 20-25°C into the upwardly inclined well section as a low-temperature liquid, and the...

Embodiment 2

[0029] A geothermal mining method of hot dry rock, which is carried out in the following steps:

[0030] Step 1. Select the target layer. The target layer is 7.5km deep and mainly composed of granite and biotite gneiss. The ground construction pressure required for rupture is 112MPa. The minimum horizontal principal stress gradient of the formation is 2.3MPa / 100m, the pressure required for the fracture extension process is 97.5MPa, with additional fluid friction and fracture friction, the hydraulic fracturing pressure drop is higher than 140MPa;

[0031] Drill two geothermal wells from the ground to the target layer, and the two geothermal wells are inclined to form inclined well sections in the target layer, and the inclination angle of the inclined well sections is 60°. Distributed above and below the target layer to form an upwardly inclined well section and a downwardly inclined well section, the horizontal distance between the upwardly inclined well section and the downw...

Embodiment 3

[0037] A geothermal mining method of hot dry rock, which is carried out in the following steps:

[0038] Step 1. Select the target layer. The target layer is 4.3km deep, mainly composed of biotite gneiss and granodiorite, with a temperature of 280-305°C, a formation dip angle of 78°, and a fracture gradient of 2.8 MPa / 100m, the minimum principal stress gradient is 2.5MPa / 100m, the pressure required for the fracture extension process is 64.5MPa, with the addition of fluid friction and fracture friction, the hydraulic fracturing pressure drop is higher than 110MPa.

[0039] Drill two geothermal wells from the ground to the target layer, and the two geothermal wells are inclined to form inclined well sections in the target layer respectively. Distributed above and below the target layer to form an upwardly inclined well section and a downwardly inclined well section, the vertical distance between the upwardly inclined well section and the downwardly inclined well section is 18m; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com