High-density fracturing fluid capable of slowing crosslinking and resisting high temperature

A high-temperature, high-density technology, applied in the field of fracturing fluid, can solve the problems of high environmental pollution of sodium bromide, low fracturing fluid density, limited liquid column pressure, etc. The effect of column pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

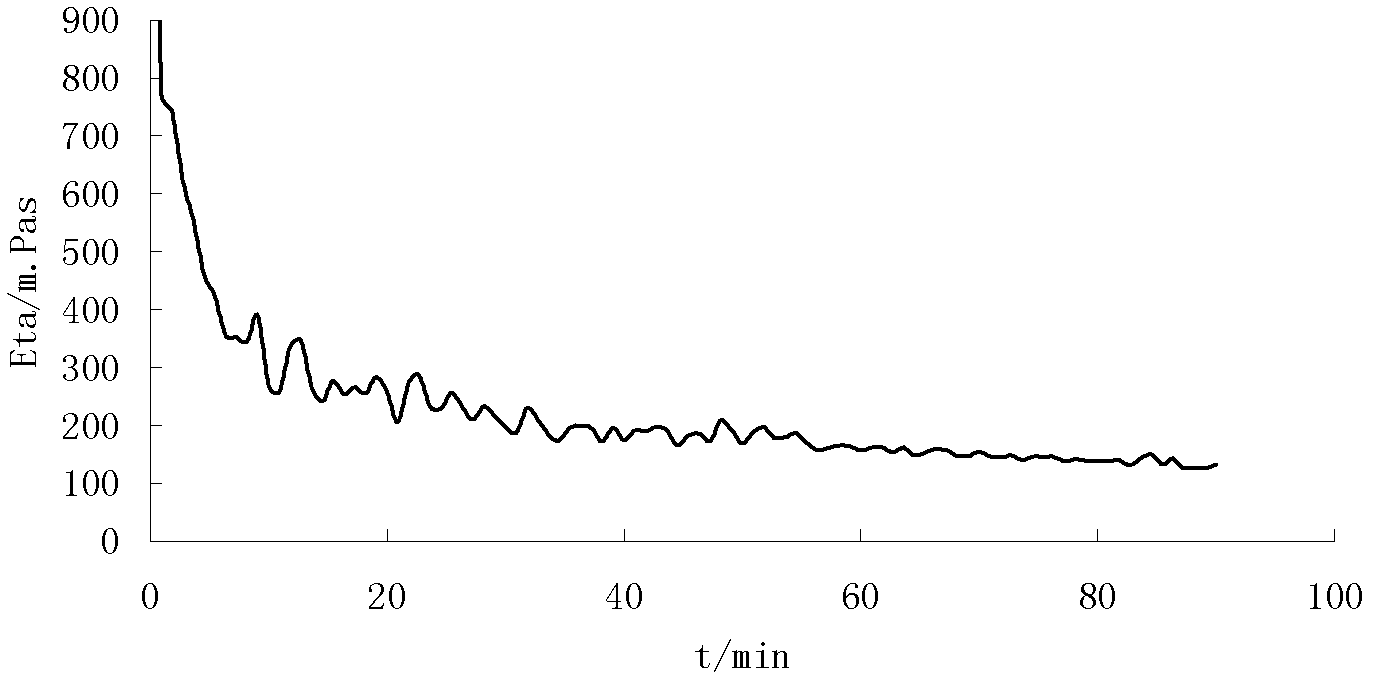

[0030] A slow-crosslinking, high-temperature, high-density, high-density fracturing fluid. The slow-crosslinking, high-temperature, high-density fracturing fluid is composed of a stock solution and crosslinking, and the volume ratio of the stock solution to the crosslinking solution is 10:1. By uniformly mixing the stock solution and the cross-linking fluid, a slow cross-linking, high-temperature, high-density fracturing fluid can be obtained.

[0031] The weight percentages of the raw materials and individual components used in the slow-crosslinking, high-temperature, high-density fracturing fluid stock solution are 0.55% hydroxypropyl guar, 44.4% weighting agent sodium nitrate, 1% ZJ-07 drainage aid, and citric acid 0.025%, the balance is water.

[0032] The weight percentages of the raw materials and components used in the slow-crosslinking, high-temperature, high-density fracturing fluid cross-linking fluid are: cross-linking agent YGB 2%, cross-linking agent HT 2%, pH regulato...

Embodiment 2

[0035] The difference from Example 1 is that the weight percentages of the raw materials and components used in the slow-crosslinking, high-temperature, high-density fracturing fluid stock solution are 0.55% hydroxypropyl guar gum, 25% sodium nitrate as a weighting agent, and weighting agent Potassium chloride 9%, ZJ-07 drainage aid 1%, citric acid 0.025%, the balance is water.

[0036] The weight percentages of the raw materials and individual components used in the slow-crosslinking, heat-resistant, high-density fracturing fluid cross-linking fluid are 2% cross-linking agent YGB, 2% cross-linking agent HT, 0.32% NaOH, and the balance is water.

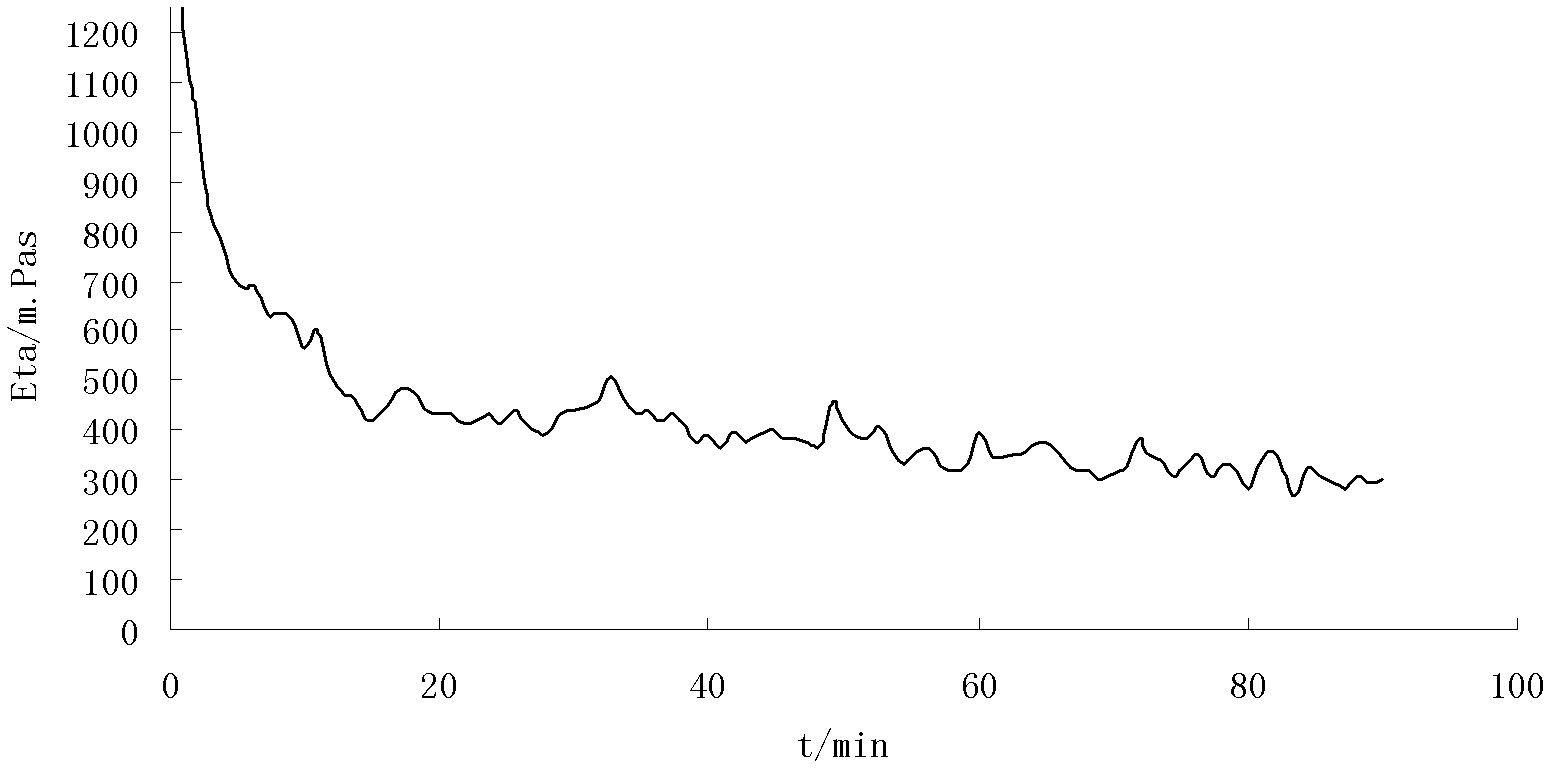

[0037] The density of the slow-crosslinking, high-temperature, high-density fracturing fluid formed by this formula is 1.21*10 3 kg / m 3 , The crosslinking time is 3min, at 140℃, 170S -1 The viscosity remains above 280Pa·S under the conditions of 90min shear. See the results of the experiment figure 2 . This formula has been successfully...

Embodiment 3

[0039] The difference from Example 1 is that the weight percentages of the raw materials and components used in the slow-crosslinking, high-temperature, high-density fracturing fluid stock solution are 0.55% hydroxypropyl guar gum, 41% sodium nitrate as a weighting agent, and weighting agent Potassium chloride 10%, ZJ-07 drainage aid 1%, citric acid 0.025%, the balance is water.

[0040] The weight percentages of the raw materials and components used in the slow-crosslinking, high-temperature, high-density fracturing fluid cross-linking fluid are: cross-linking agent YGB 1.5%, cross-linking agent HT 1.5%, NaOH 0.2%, sodium persulfate 0.4%, and the rest The amount is water.

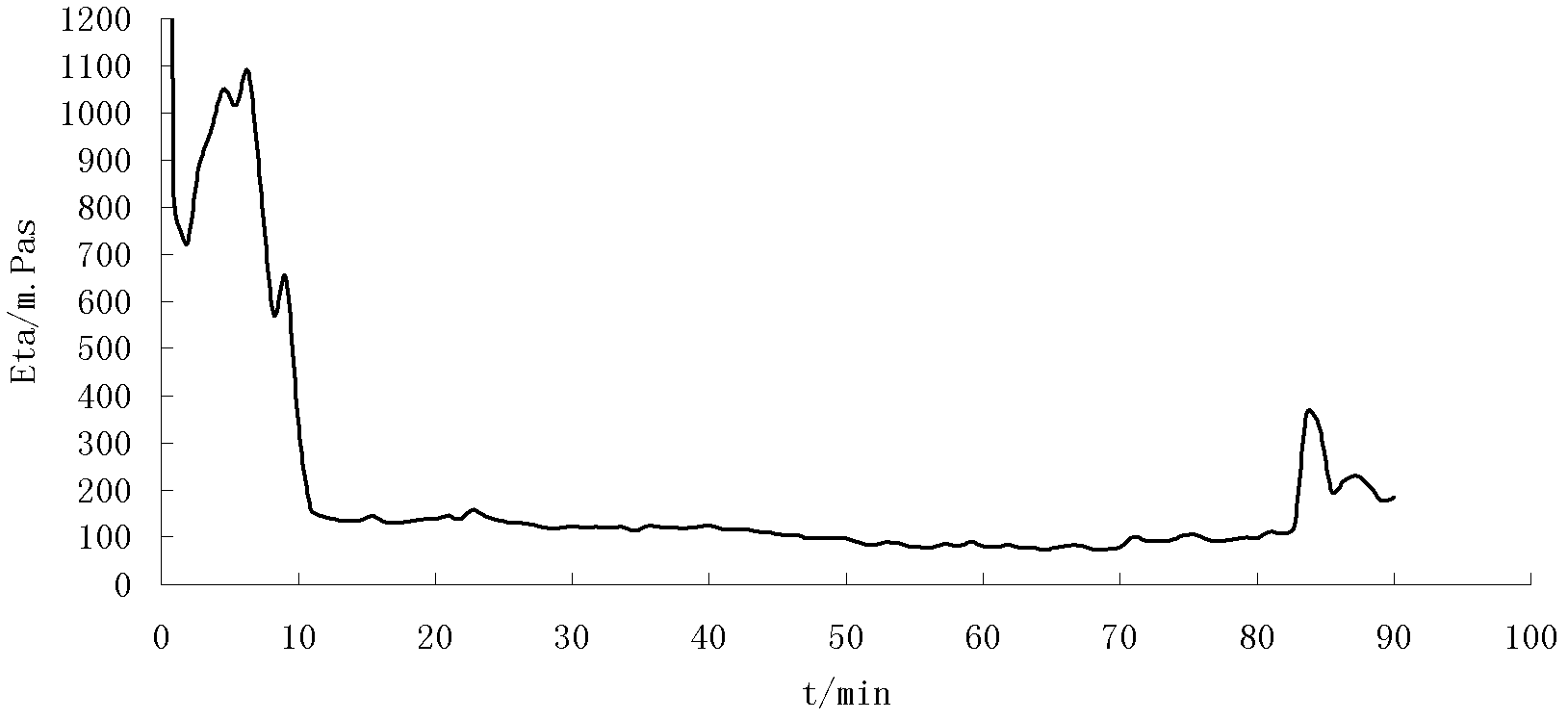

[0041] The density of the formed slow-crosslinking, high-temperature, high-density fracturing fluid is 1.33*103kg / m 3 , Crosslinking time is 2min. This formula is at 100℃, 170S without gel breaker -1 The viscosity remains above 100Pa·S under the conditions of 90min shearing. See the results of the experiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com