Surfactant fracturing fluid capable of recycling and preparation method

A surfactant and fracturing fluid technology, which is applied in the field of oilfield fracturing fluid, can solve problems such as difficult flowback fluid treatment, complex system composition, and poor temperature resistance, and achieve water and additive saving, cost reduction, and simple formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

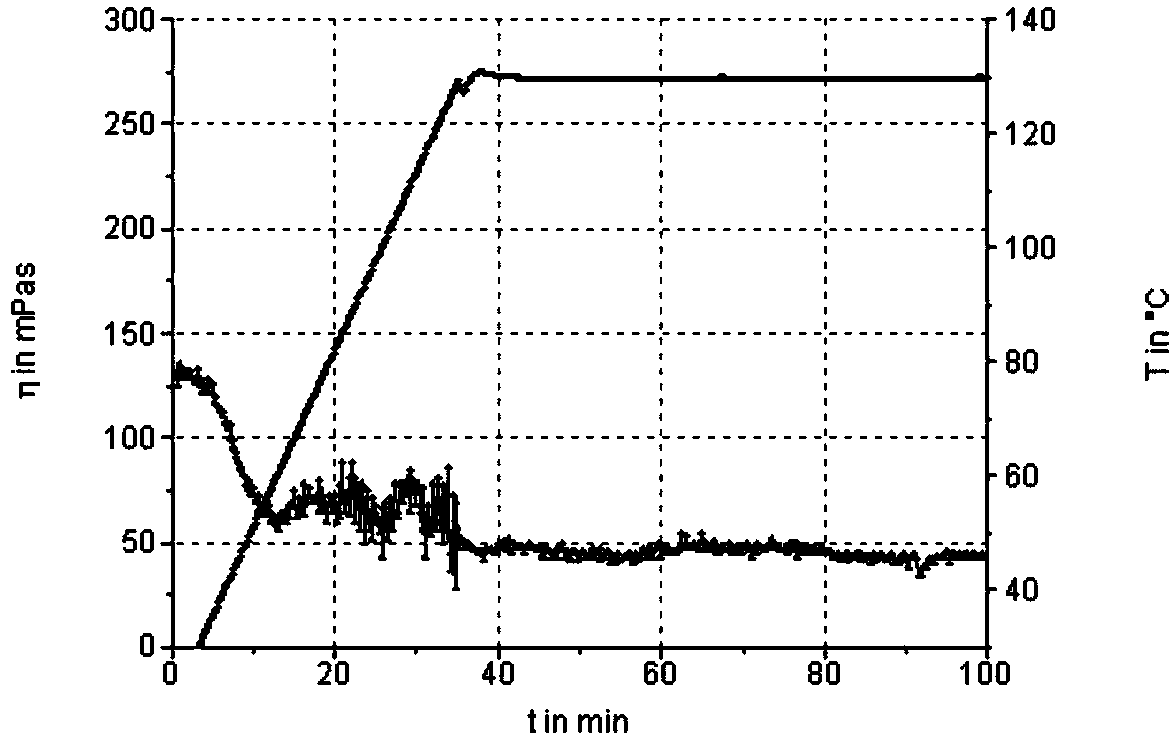

Image

Examples

preparation example Construction

[0018] The preparation method of the reusable surfactant type fracturing fluid of the present invention comprises the following steps:

[0019] (1) Mix organic acid and N,N-dimethyl-1,3-propanediamine compound evenly, heat to 150-180°C for 4-6 hours, cool to room temperature, and react to obtain an intermediate;

[0020] (2) Mix the intermediate and the dihalide evenly in an aqueous ethanol solution, stir and heat up to 60-90°C, react for 3-5 hours, and cool to room temperature to obtain a surfactant;

[0021] (3) According to mass percentage, add 2%-4% surfactant and 1%-3% halide aqueous solution into water and stir evenly to obtain surfactant fracturing fluid;

[0022] Organic acid: N,N-dimethyl-1,3-propanediamine: the molar ratio of dihalide: 1:(1.05-1.10):(0.45-0.48); the amount of ethanol aqueous solution is the total amount of reactants 8-10% of the mass.

[0023] The organic acid is C18-C20, C24 long chain unsaturated fatty acid.

[0024] The dihalide is X(CH 2 ) n...

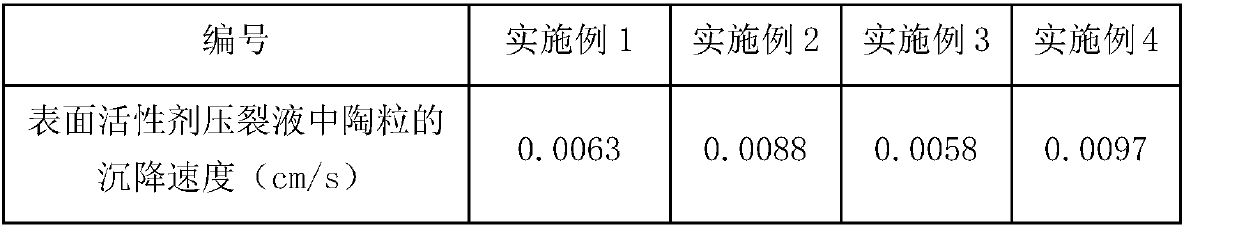

Embodiment 1

[0030] Feeding molar ratio: linolenic acid: N,N-dimethyl-1,3-propylenediamine: dihalide = 1:1.05:0.45; ethanol aqueous solution (mass percentage concentration 50%, the same below) is added as the reactant 8% of the total mass.

[0031] After mixing linolenic acid and N,N-dimethyl-1,3-propanediamine compound evenly, heating to 150°C for 4 hours, cooling to room temperature, and reacting to obtain an intermediate. The intermediate and 1,2-dichloroethane were uniformly mixed in an aqueous ethanol solution (50%), stirred and heated to 70°C, reacted for 4 hours, cooled to room temperature, and a surfactant was obtained. 2% surfactant and 1% potassium chloride aqueous solution (20%) are sequentially added into water and stirred evenly to obtain surfactant fracturing fluid.

Embodiment 2

[0033] Feeding molar ratio: eicosenoic acid: N, N-dimethyl-1,3-propanediamine: dihalide = 1:1.08:0.47; the amount of ethanol aqueous solution (50%) is 10% of the total mass of reactants %.

[0034] After mixing eicosenoic acid and N,N-dimethyl-1,3-propanediamine compound evenly, heat to 160°C for 5 hours, cool to room temperature, and react to obtain an intermediate. The intermediate and 1,2-dichloropropane were uniformly mixed in an aqueous ethanol solution (50%), stirred and heated to 80°C, reacted for 4 hours, and cooled to room temperature to obtain a surfactant. 3% surfactant and 2% ammonium chloride aqueous solution (20%) are sequentially added into water and stirred evenly to obtain surfactant fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com