Preparation method of double epoxy compound crosslinking agent modified xanthan gum

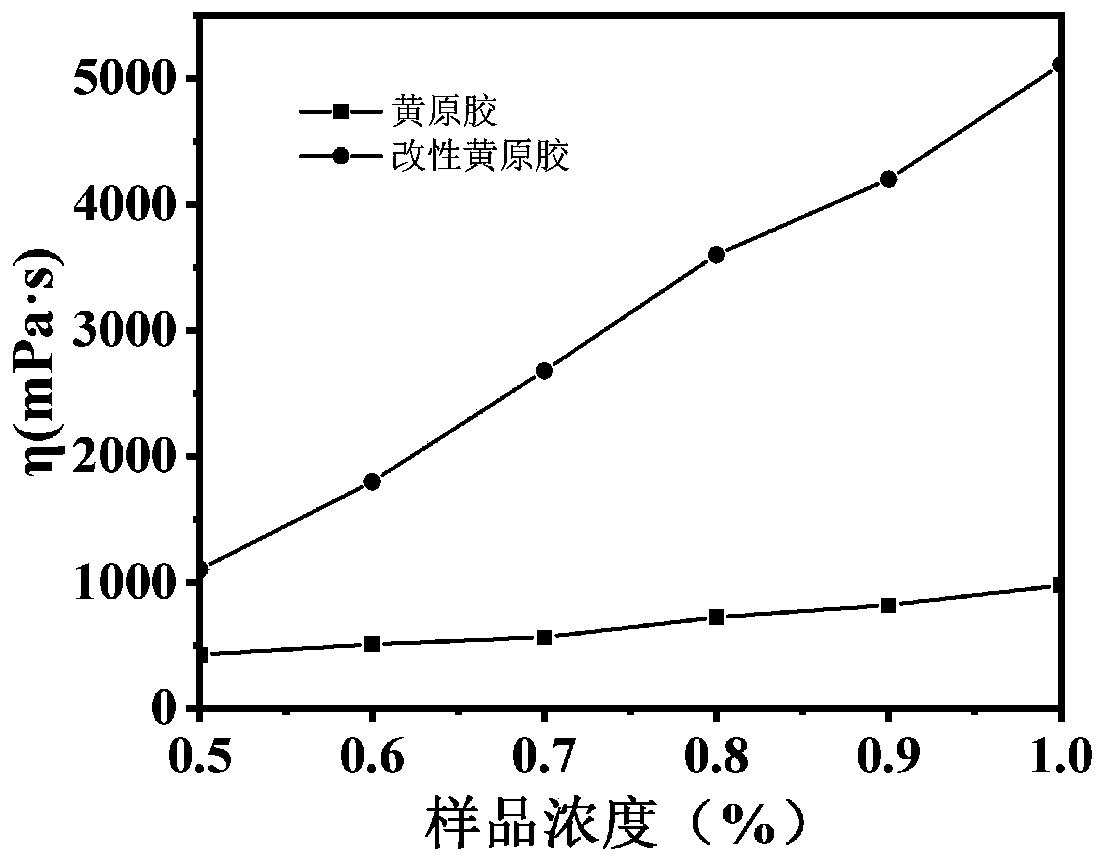

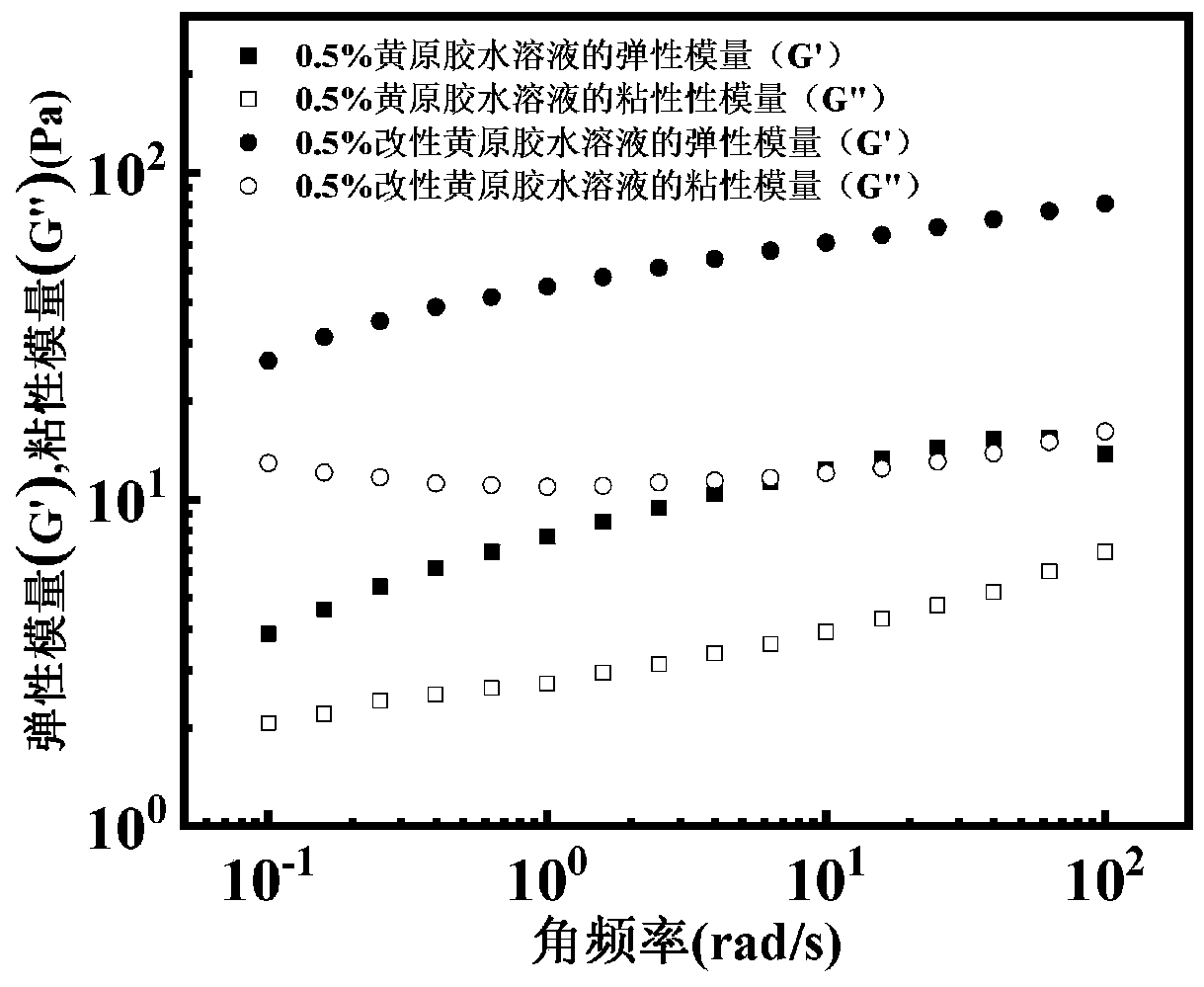

A technology of diepoxy compound and xanthan gum, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as human or environmental hazards, toxicity, etc., to reduce the amount of crosslinking agent, product safety, and stickiness The effect of increased resilience and network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, dissolving 2g of xanthan gum in 100mL of deionized water, stirring slowly at room temperature for 6h to fully dissolve the xanthan gum to obtain a xanthan gum solution;

[0036] Step 2, add 1mol / L NaOH solution to adjust the pH of the above xanthan gum solution to 10, then add dropwise 0.02g of 1.4-butanediol diglycidyl ether as a crosslinking agent, and stir evenly, then heat up the water bath to 40°C for reaction 4h;

[0037] Step 3, the reaction product was settled with 80% ethanol solution, filtered and washed three times with absolute ethanol, and finally dried in a blast drying oven at 60°C to obtain modified xanthan gum, numbered as No. 1 in Table 1. .

Embodiment 2

[0039] As in Example 1, but in step 2, the pH of the solution was adjusted to 11, the mass of 1.4-butanediol diglycidyl ether was added dropwise to 0.06 g, the reaction time was 6 h, and the number was No. 2 in Table 1.

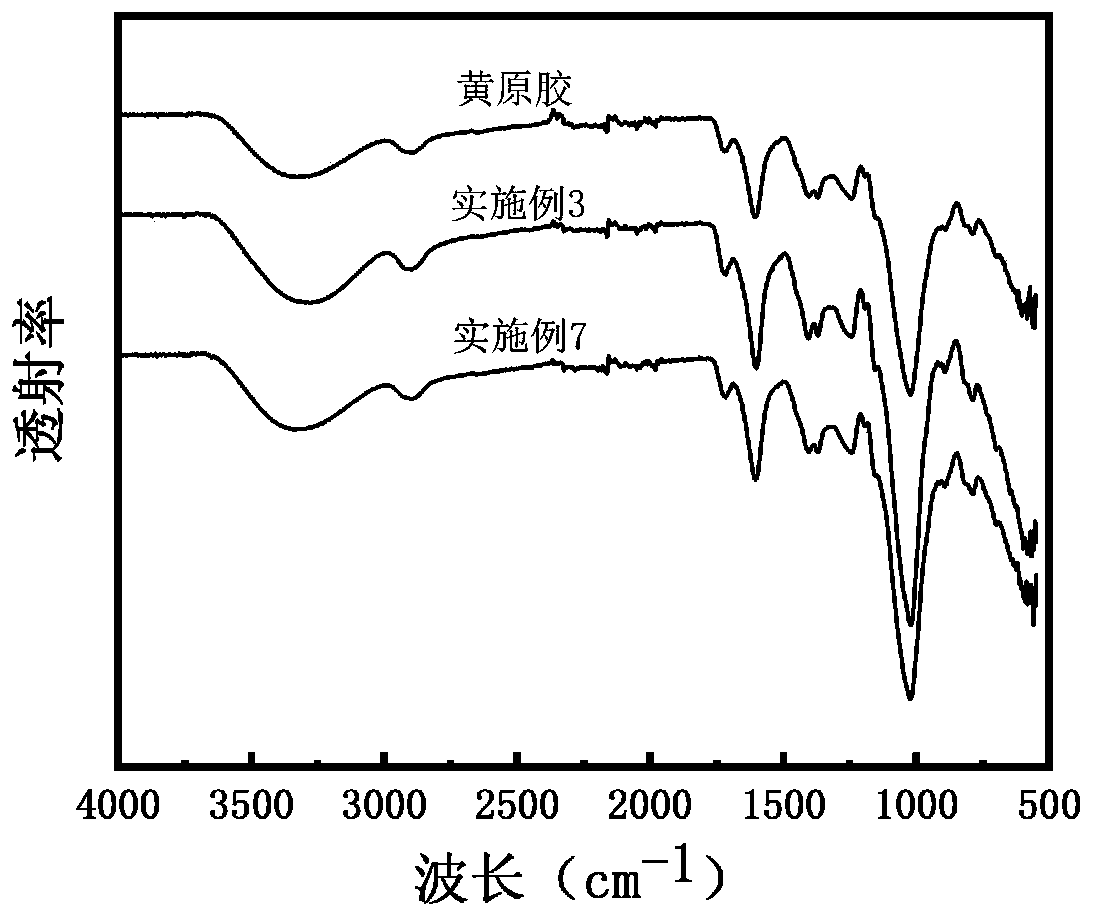

Embodiment 3

[0041] As in Example 1, but in step 2, the pH of the solution was adjusted to 11, the reaction time was 8 hours, the mass of 1.4-butanediol diglycidyl ether was added dropwise to 0.1 g, and the number was No. 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com