Association type high-temperature resistant fracturing fluid suitable for volcanic rock fracture

An associative, high-temperature-resistant technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of not having universal applicability, poor temperature resistance, high residue content, etc., and achieve good shear resistance , Structural stability, and the effect of reducing construction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

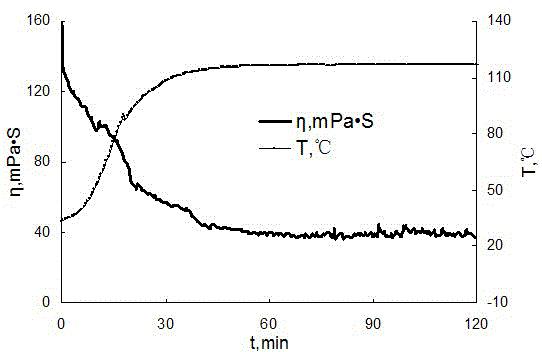

Embodiment 1

[0046] Example 1: An associative high-temperature resistant fracturing fluid suitable for volcanic rock fracturing, which consists of two parts: base fluid and additives during construction; the weight percentages of the components of the base fluid are: thickener 0.5%, flow enhancer 0.2% %, the balance is water; during construction, additives include thickening auxiliary agent and gel breaker, and the weight percentage of additive components in base liquid during construction is: thickening auxiliary agent is 0.25%, and gel breaker is 0.02%.

[0047] The thickener of the base liquid is a hydrophobic association polymer, which is based on acrylic acid, acrylamide, monocetyl maleate sodium salt and an anionic monomer allyl sulfonate and water As the reaction raw material, it is prepared by reacting at a certain temperature with sodium lauryl sulfate as the emulsifier and azobisisobutyronitrile as the initiator.

[0048] The method of making the thickener of the base liquid is...

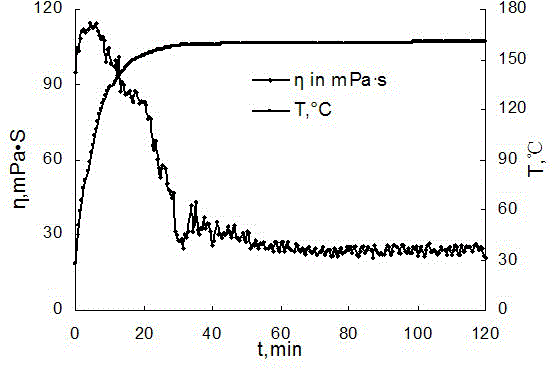

Embodiment 2

[0071] Example 2: An associative high-temperature resistant fracturing fluid suitable for volcanic rock fracturing, which consists of two parts: base fluid and additives during construction; the weight percentage of the components of the base fluid is: thickener 0.9%, flow accelerator 0.3% %, the balance is water; during construction, additives include thickening auxiliary agent and gel breaker, and the weight percentage of additive components in base liquid during construction is: thickening auxiliary agent is 0.45%, and gel breaker is 0.05%;

[0072] The thickener of the base liquid is a hydrophobic association polymer, which is based on acrylic acid, acrylamide, monocetyl maleate sodium salt and an anionic monomer allyl sulfonate and water As the reaction raw material, it is prepared by reacting at a certain temperature with sodium lauryl sulfate as the emulsifier and azobisisobutyronitrile as the initiator.

[0073] The thickener of the base liquid is prepared as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com