Method for improving highly argillaceous sandstone layer

A kind of muddy sandstone and reservoir technology, which is applied in the field of downhole operation and transformation of strata, can solve the problems of fracturing design regardless of formation conditions and pressure failure, so as to achieve the effect of increasing single well production, reducing construction pressure and improving stimulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1, a method for transforming a high-shale sandstone layer. In the construction process, after sandblasting and perforating, the reservoir is firstly treated with an acid solution, and then the pre-fluid is injected and the sand plug is treated, and then the carrying fluid is injected. The sand liquid finally broke through the formation successfully. The acid solution includes HCL, HF, demulsifier, clay stabilizer, citric acid and corrosion inhibitor, and the mass percentage of each component is 10-12% HCL, 3.0-6.0% HF, 0.5% demulsifier, 0.3% clay stabilizer, 0.1% citric acid and 1.0% corrosion inhibitor, the rest is water.

[0017] In this embodiment, the acid solution is used to pretreat the reservoir in the well before the prefluid is injected, which effectively reduces the construction pressure, finally successfully breaks the formation, and improves the success rate of high-shale sandstone fracturing and the effect of reservoir stimulation.

Embodiment 2

[0018] Example 2. This example is to reform the high-shale sandstone layer of Well GP33-21. The physical property data of the first section of the well at 2368.0 m: the acoustic time difference is 209.75 μs / m, and the shale content is 23.33%.

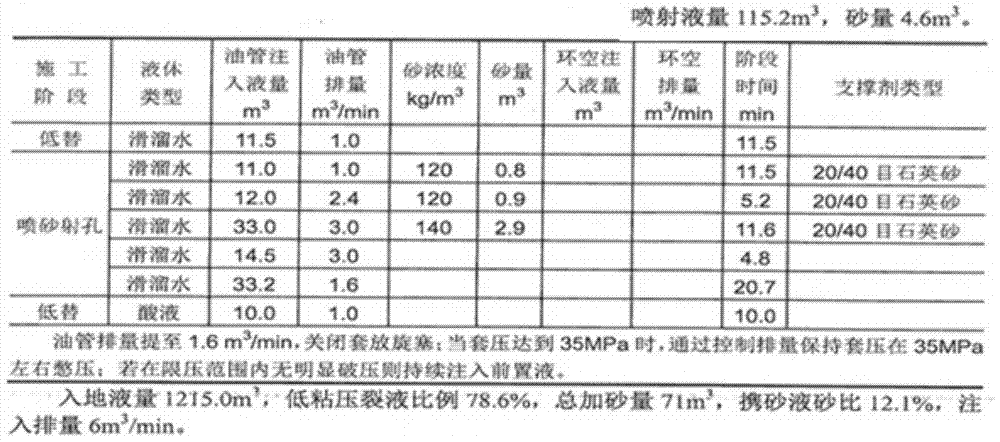

[0019] During the construction of this example, after the perforation is completed, 20m of acid solution is injected twice. 3 Pretreatment, the mass percentage of each component of the acid solution: 12% HCl, 6.0% HF, 0.5% demulsifier (CF-5C, produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), 0.3% clay stabilizer (COP-1 , produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), 0.1% citric acid and 1.0% corrosion inhibitor (HJF-94, produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), the rest is water, shut down the well for 2 hours. Front liquid volume 220m 3 , the volume ratio of the pre-fluid and the sand-carrying fluid is 120:100, and the sand concentration in the pre-fluid stage is 30kg / m 3 The s...

Embodiment 3

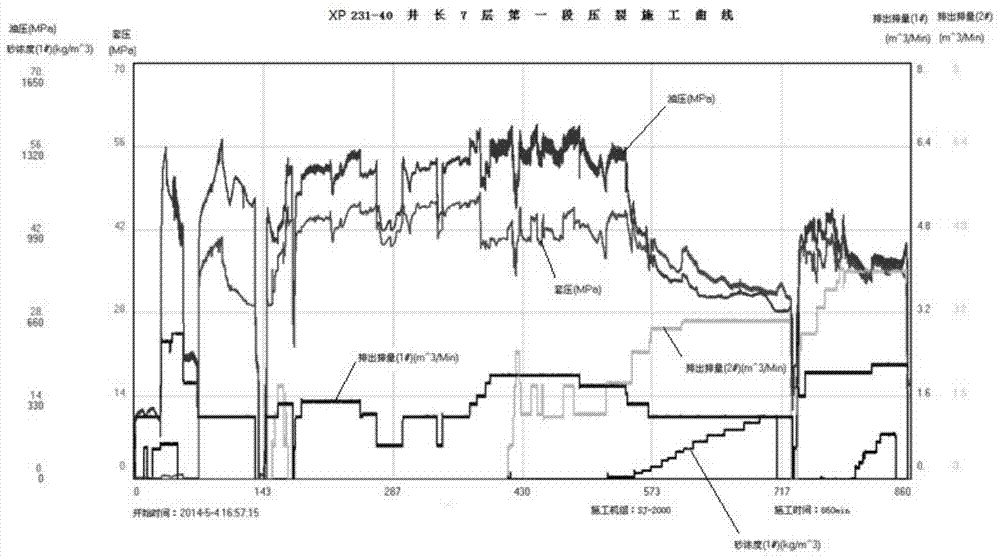

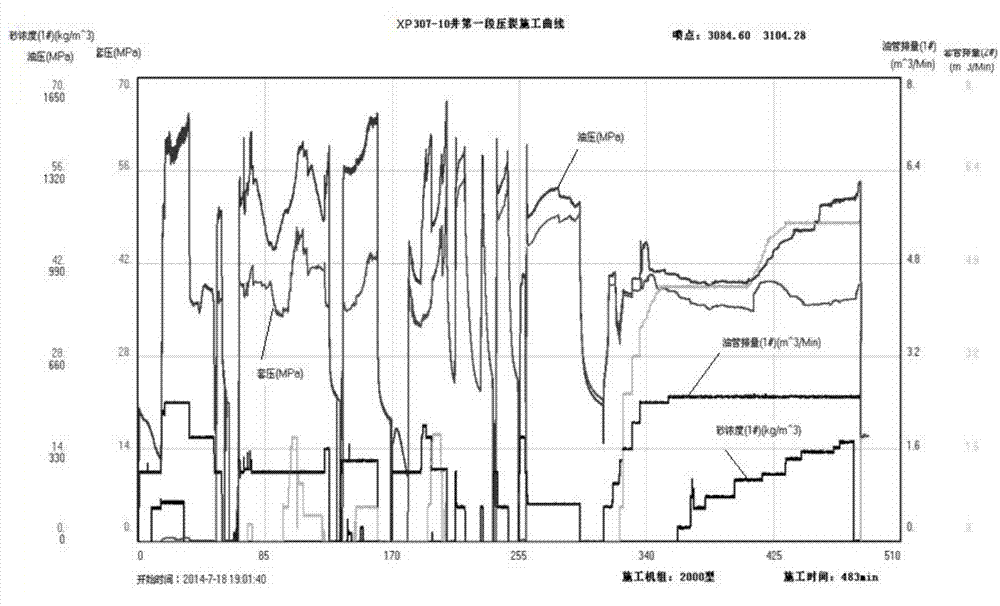

[0020] Example 3, this example is the reconstruction of the high shale sandstone layer in Well HP3-11, the physical property data of the first section of the well at 3176.0 and 3186.0m: the acoustic time difference is 205.57μs / m, and the shale content is 20.3%.

[0021] In the construction process of this embodiment, after the perforation is completed, 20m of acid solution is injected 3 Pretreatment, the mass percentage of each component of the acid solution: 10% HCl, 3.0% HF, 0.5% demulsifier (CF-5C, produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), 0.3% clay stabilizer (COP-1 , produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), 0.1% citric acid and 1.0% corrosion inhibitor (HJF-94, produced by Xi'an Changqing Chemical Petroleum Group Co., Ltd.), the rest is water, shut down the well for 2 hours. Prefluid volume 216.5m 3 , the volume ratio to the sand-carrying liquid is 100:100, and the sand concentration in the pre-fluid stage is 15-50kg / m 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com