Acid polymer weighted fracture fluid and preparation method thereof

An acid polymer, fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of indeterminate, alkali-sensitive formation damage, high molecular weight of guar gum thickener, and achieve good resistance Temperature and shear resistance, reduced wellhead construction pressure, and adjustable cross-linking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

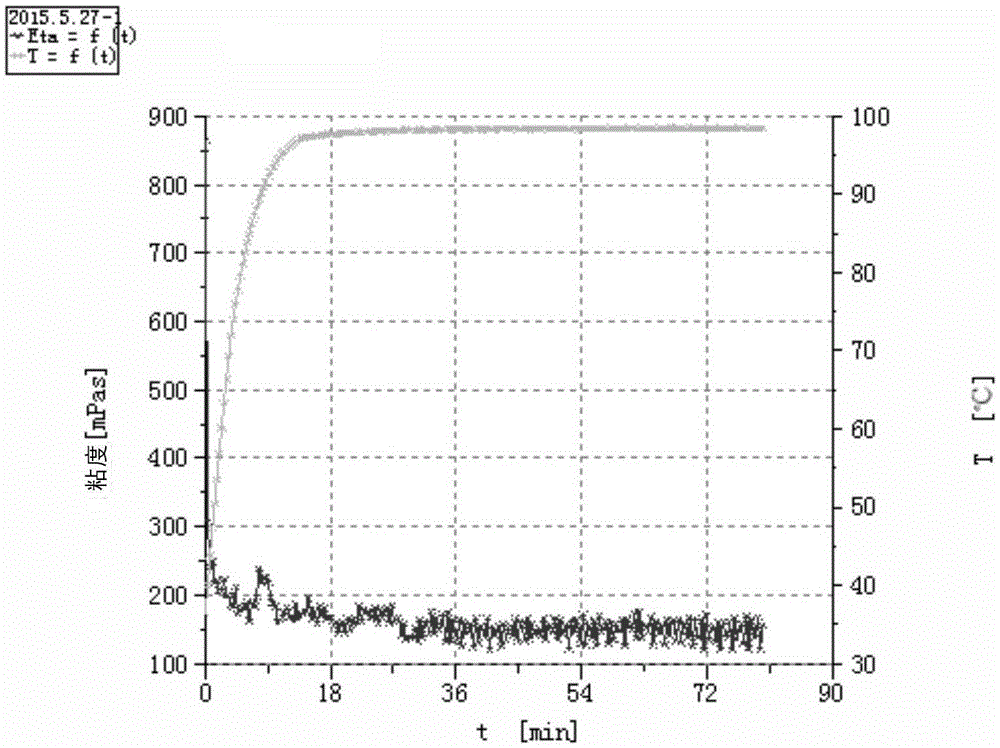

Embodiment 1

[0057] The acidic polymer weighted fracturing fluid of this embodiment is composed of base fluid, crosslinking fluid and gel breaker;

[0058] The base liquid is composed of the following components by weight percentage: weighting agent 20%, polymer thickener 0.8%, drainage aid 0.2%, and the balance is water; the weighting agent is potassium chloride;

[0059] The cross-linking liquid is composed of an organoaluminum-zirconium delayed cross-linking agent and an organoaluminum-zirconium cross-linking agent, and the weight ratio of the organoaluminum-zirconium delayed cross-linking agent to the organoaluminum-zirconium cross-linking agent is 1.5:3.5; the cross-linking liquid The mass is 0.6% of the mass of the base fluid;

[0060] The gel breaker is a capsule gel breaker, and the mass of the gel breaker is 0.03% of the mass of the base liquid.

[0061] The acidic polymer weighted fracturing fluid preparation method of the present embodiment comprises the following steps:

[00...

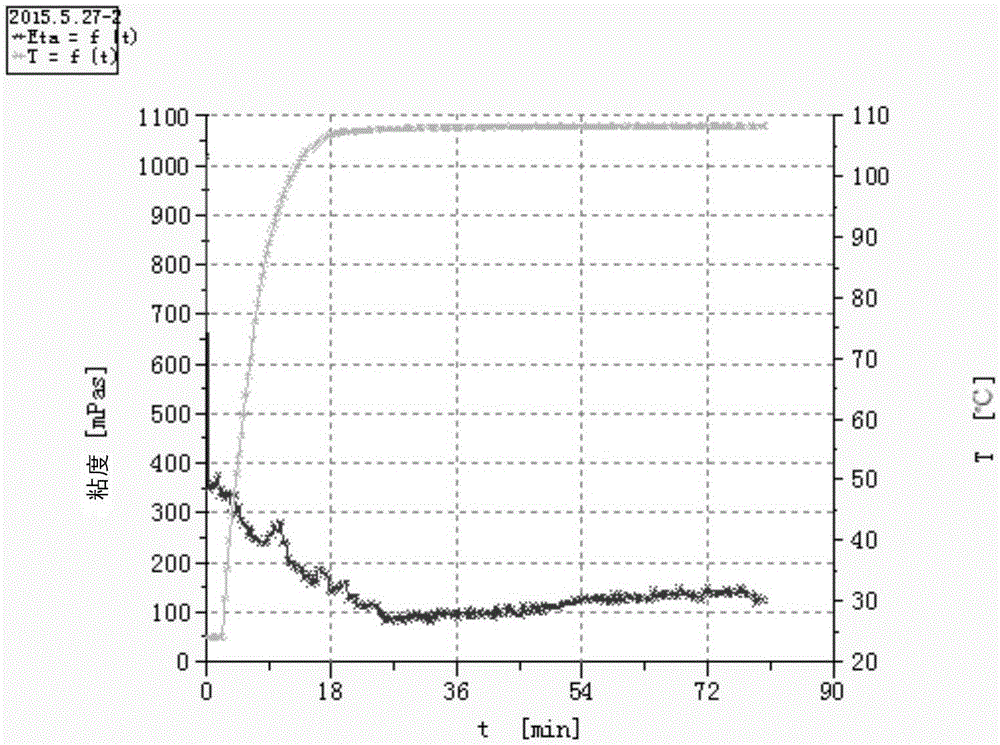

Embodiment 2

[0067] The acidic polymer weighted fracturing fluid of this embodiment is composed of base fluid, crosslinking fluid and gel breaker;

[0068] The base liquid is composed of the following components by weight percentage: weighting agent 34%, polymer thickener 0.9%, drainage aid 0.2%, and the balance is water; the weighting agent is potassium chloride and potassium bromide A mixture with a mass ratio of 1:3;

[0069] The cross-linking liquid is composed of an organoaluminum-zirconium delayed cross-linking agent and an organoaluminum-zirconium cross-linking agent, and the weight ratio of the organoaluminum-zirconium delayed cross-linking agent to the organoaluminum-zirconium cross-linking agent is 1.5:4.0; the cross-linking liquid The mass is 0.6% of the mass of the base fluid;

[0070] The gel breaker is a capsule gel breaker, and the quality of the gel breaker is 0.02% of the mass of the base liquid.

[0071] The acidic polymer weighted fracturing fluid preparation method of...

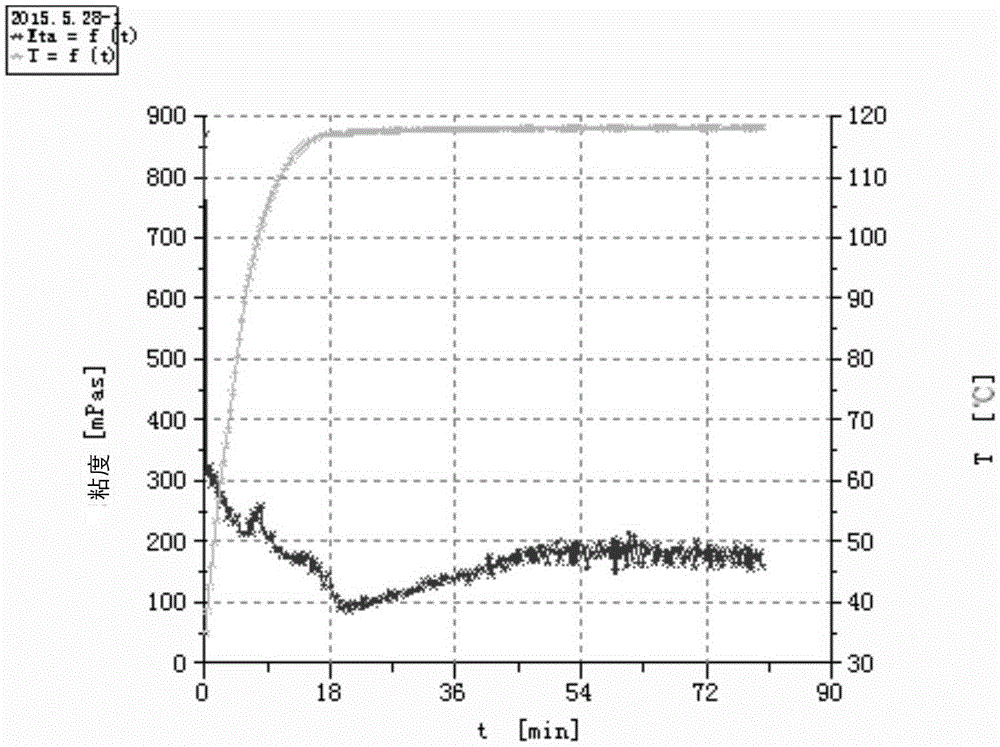

Embodiment 3

[0077] The acidic polymer weighted fracturing fluid of this embodiment is composed of base fluid, crosslinking fluid and gel breaker;

[0078] The base liquid is composed of the following components by weight percentage: weighting agent 35%, polymer thickener 1.0%, drainage aid 0.2%, and the balance is water; the weighting agent is potassium bromide and sodium bromide A mixture with a mass ratio of 1:4;

[0079] The cross-linking liquid is composed of an organoaluminum-zirconium delayed cross-linking agent and an organoaluminum-zirconium cross-linking agent, and the weight ratio of the organoaluminum-zirconium delayed cross-linking agent to the organoaluminum-zirconium cross-linking agent is 2.0:4.5; the cross-linking liquid The mass is 0.7% of the mass of the base fluid;

[0080] The gel breaker is a capsule gel breaker, and the mass of the gel breaker is 0.03% of the mass of the base liquid.

[0081] The acidic polymer weighted fracturing fluid preparation method of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com