Micro-pit electrolytic micro-bubble generator based on micro-drill hole making on electrode wall

A technology for micro-bubble generation and micro-pits, which is applied in transportation and packaging, ship hull, and ship construction, etc. problem, to achieve the effect of stable residence, improved residence rate, and high roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

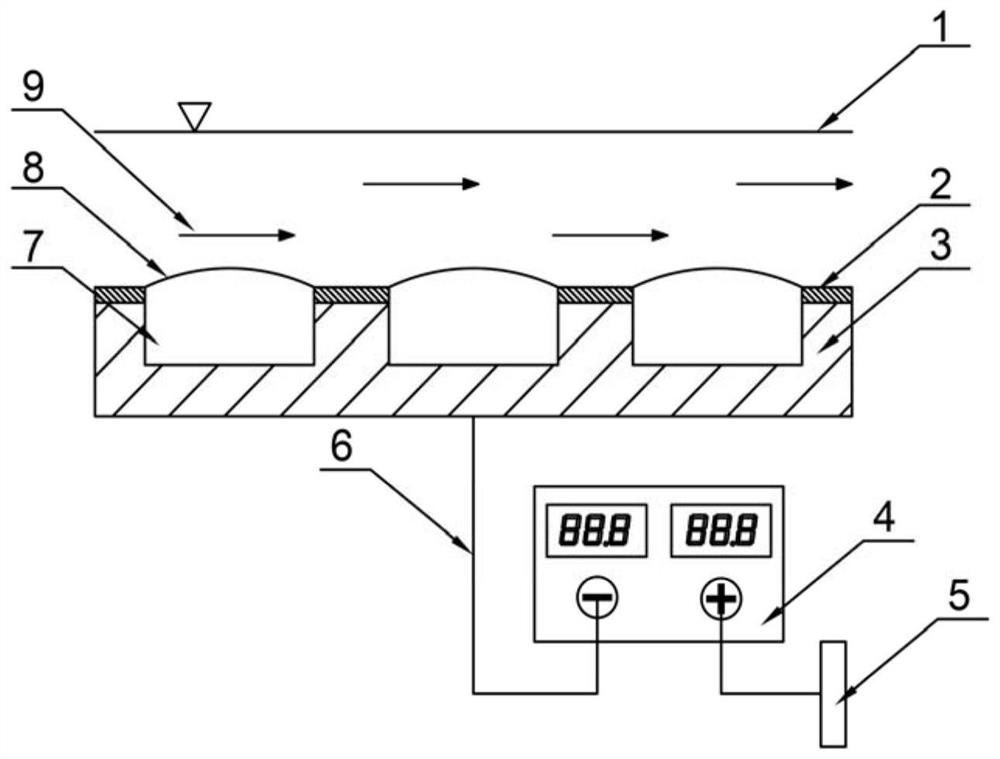

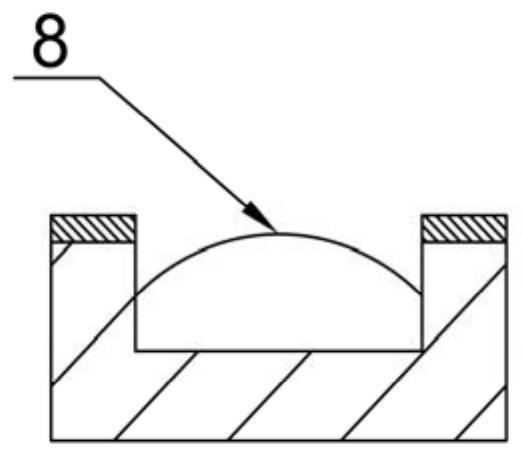

[0032] Such as figure 1 As shown, in this embodiment, the electrode wall micro-pit electrolytic micro-bubble generating device based on the micro-drill making holes includes a substrate 3, a DC stabilized power supply 4 and a carbon rod 5;

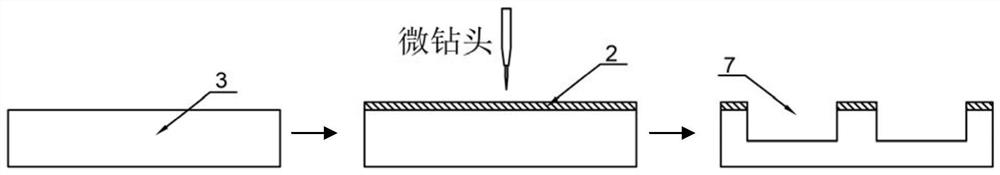

[0033] The base body 3 is made of metal copper sheet, and the surface of the base body 3 is evenly distributed or arranged at linearly increased intervals with cylindrical electrode wall micro-pits 7, the diameter of the electrode wall micro-pits 7 is 40-400 μm, and the depth is 20-200 μm ;

[0034] The upper surface of the substrate 3 is covered with a polyimide coating 2, and the material of the polyimide coating 2 is liquid polyimide; the micro pits 7 on the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com