Composite bionic surface jet nozzle

A jet nozzle, super-hydrophobic surface technology, applied in the direction of spraying device, spraying device, etc., can solve the problem that the effect of drag reduction needs to be further improved, and achieve the effect of reducing drag and increasing the distance of jet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the drawings and embodiments:

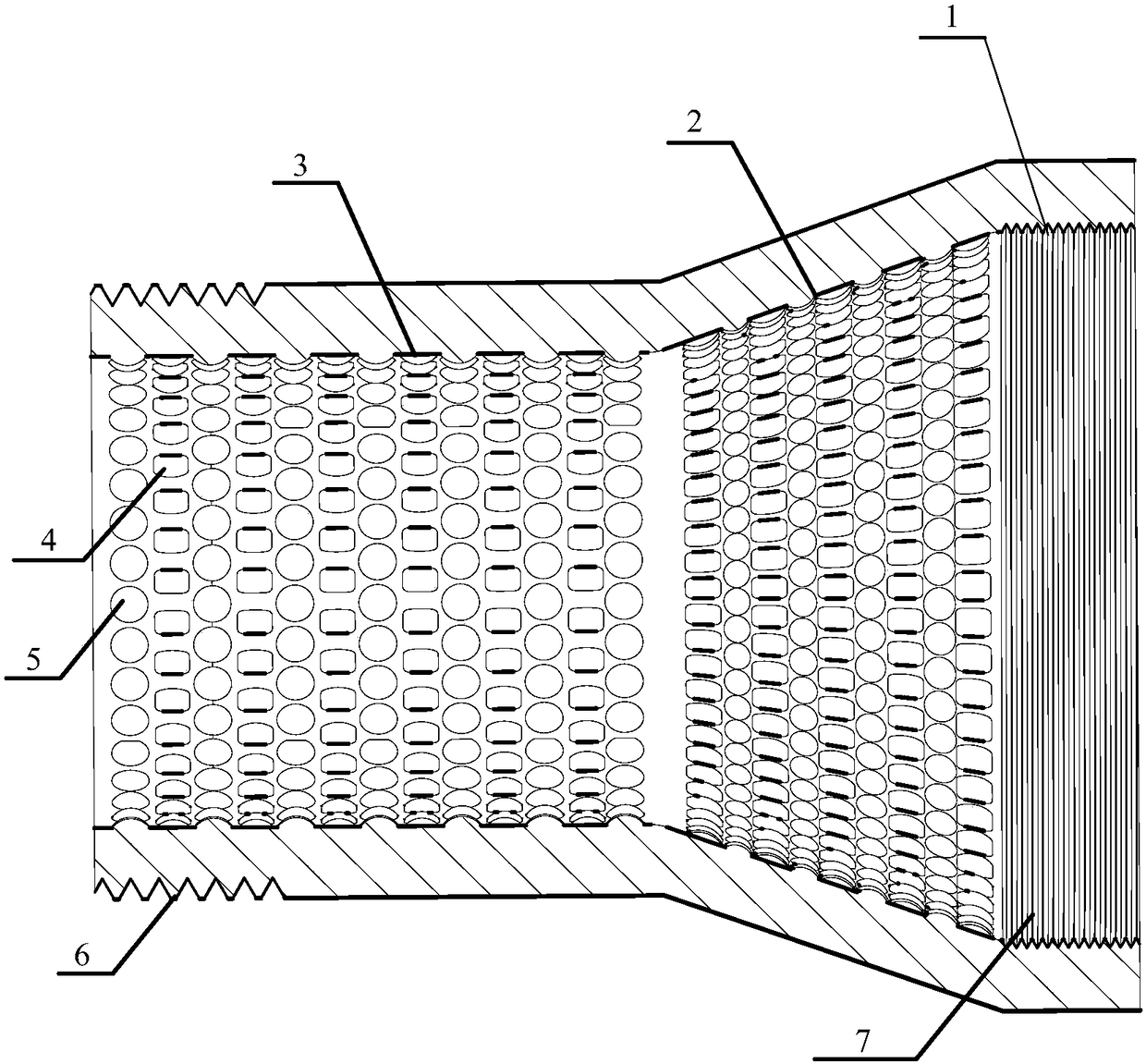

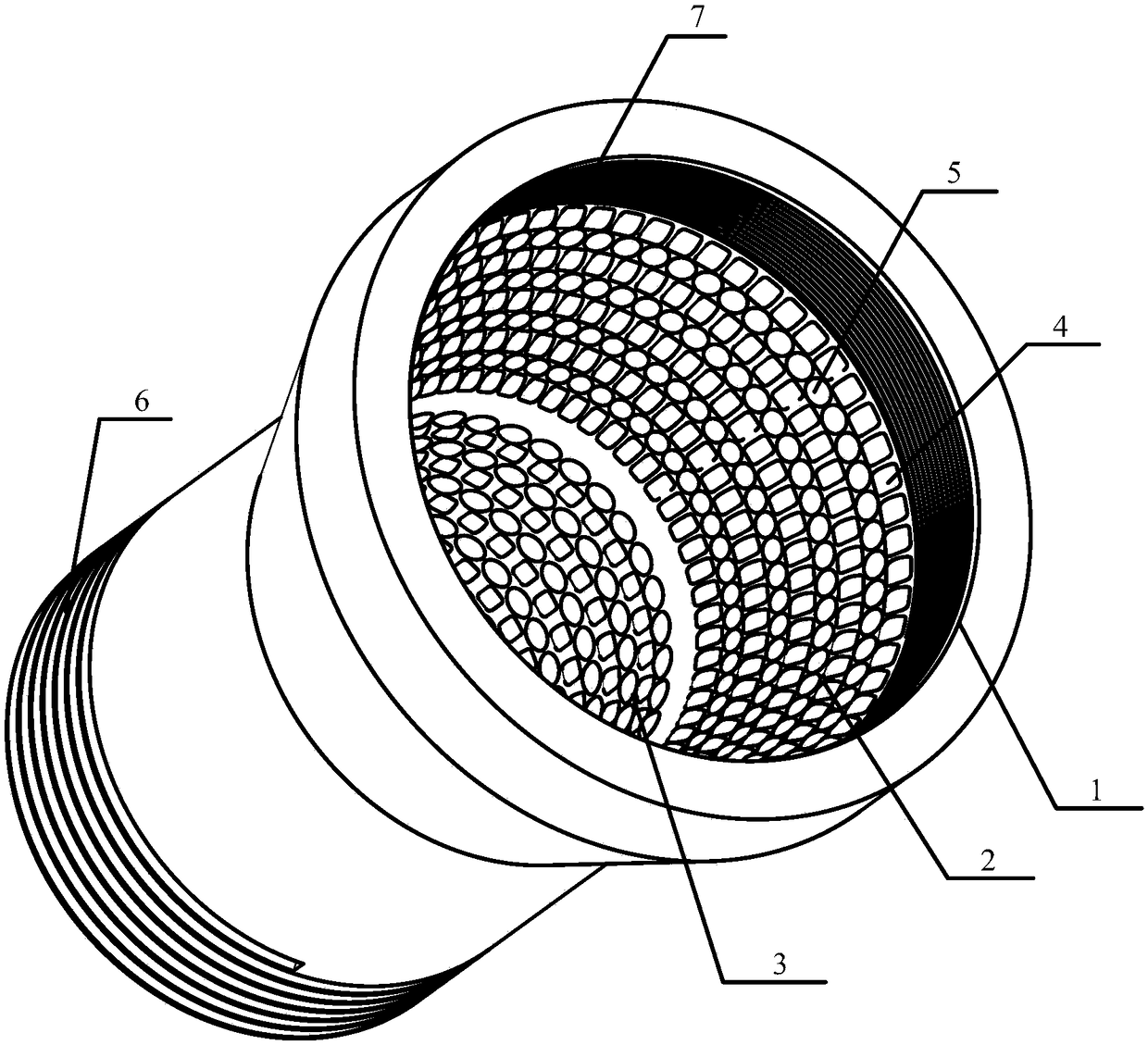

[0010] in figure 1 with figure 2 The schematic diagram of the composite bionic surface jet nozzle shown is divided into three sections, namely an inlet section 1, a contraction section 2 and an outlet section 3. The inlet section is an equal-diameter round tube with threads 7 on its inner surface. , The non-free end of the inlet section is connected with the large-diameter end of the truncated cone-shaped tube of the contraction section. The inner wall of the truncated cone-shaped tube is a composite bionic surface composed of bionic shark skin drag reducing surface 4 and bionic superhydrophobic surface 5 The shark skin drag reduction surface is rectangular protrusions, the ratio of length to width is 2.5, and the heights of the protrusions are all equal, but cannot exceed 0.025 times the minimum diameter of the surface. The periphery and the inner wall are smoothly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com