Refrigerated prepared instant sharkskin and preparation method thereof

A technology of shark skin and formula, which is applied in the field of refrigerated conditioning ready-to-eat shark skin and its preparation, to achieve the effect of improving the crispy taste and prolonging the shelf life of fresh goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

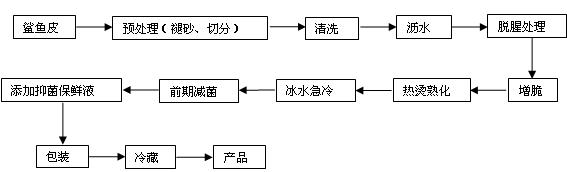

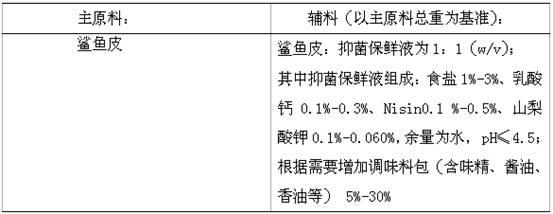

Method used

Image

Examples

Embodiment 1

[0028] Sand removal: After rehydrating the dried shark skin, put it in boiling water for 30 minutes, remove it, put it in ice water to cool, and remove the sand.

[0029] Cutting: cut the shark skin into 1.0×2.0cm 2 The size is blocky, try to keep the size consistent.

[0030] Deodorization treatment: soak the pretreated shark skin in 0.05% (weight ratio, the same below) organic acid solution, 0.60% ginger juice solution, 0.2% black tea water, the soaking time is 60min respectively, which can effectively remove the fishy smell of shark skin.

[0031] Embrittlement treatment: soak the deodorized shark skin in an embrittlement solution with a weight ratio of 0.1% calcium lactate and 0.6% sodium hexametaphosphate for 60 minutes.

[0032] Blanching and curing: Rinse the deodorized shark skin with clean water, and scald it in boiling water for 2 minutes.

[0033] Quenching in ice water: immediately put the blanched shark skin into sterile ice water for 10 minutes to improve the ...

Embodiment 2

[0039] Sand removal: After rehydrating the dried shark skin, put it in boiling water for 30 minutes, remove it, put it in ice water to cool, and remove the sand.

[0040] Cutting: cut the shark skin into 1.5×3.0cm 2 The size is blocky, try to keep the size consistent.

[0041] Deodorization treatment: Soak pretreated shark skin in 0.3% organic acid solution, 0.10% ginger juice solution, 0.05 % black tea water, the soaking time is 30min, which can effectively remove the fishy smell of shark skin.

[0042] Embrittlement treatment: Soak the deodorized shark skin in an embrittlement solution with a concentration of 0.3% calcium lactate and 0.3% sodium hexametaphosphate for 20 minutes.

[0043] Blanching and curing: Rinse the deodorized shark skin with clean water, and scald it in boiling water for 5 minutes.

[0044] Quenching in ice water: The blanched shark skin is immediately put into sterile ice water for 20 minutes to improve the crispness of the shark skin.

[0045] Pre-...

Embodiment 3

[0050] Sand removal: After rehydrating the dried shark skin, put it in boiling water for 30 minutes, remove it, put it in ice water to cool, and remove the sand.

[0051] Cutting: cut the shark skin into 1.5×1.5cm 2 The size is blocky, try to keep the size consistent.

[0052]Deodorization treatment: Soak pretreated shark skin in 0.15% organic acid solution, 0.3% ginger juice solution, 0.1 % black tea water, the soaking time is 45min, which can effectively remove the fishy smell of shark skin.

[0053] Embrittlement treatment: Soak the deodorized shark skin in an embrittlement solution with a concentration of 0.3% calcium lactate and 0.1% sodium hexametaphosphate for 40 minutes.

[0054] Blanching and curing: Rinse the deodorized shark skin with clean water, and scald it in boiling water for 3 minutes.

[0055] Quenching in ice water: The blanched shark skin is immediately put into sterile ice water for 15 minutes to improve the crispness of the shark skin.

[0056] Pre-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com