VF tofu skin crisp chips and preparation method thereof

A technology of bean curd and chips, which is applied in the field of bean curd chips and its preparation, can solve the problems of few products and low technical content, and achieve the effects of prolonged storage period, low temperature and less loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

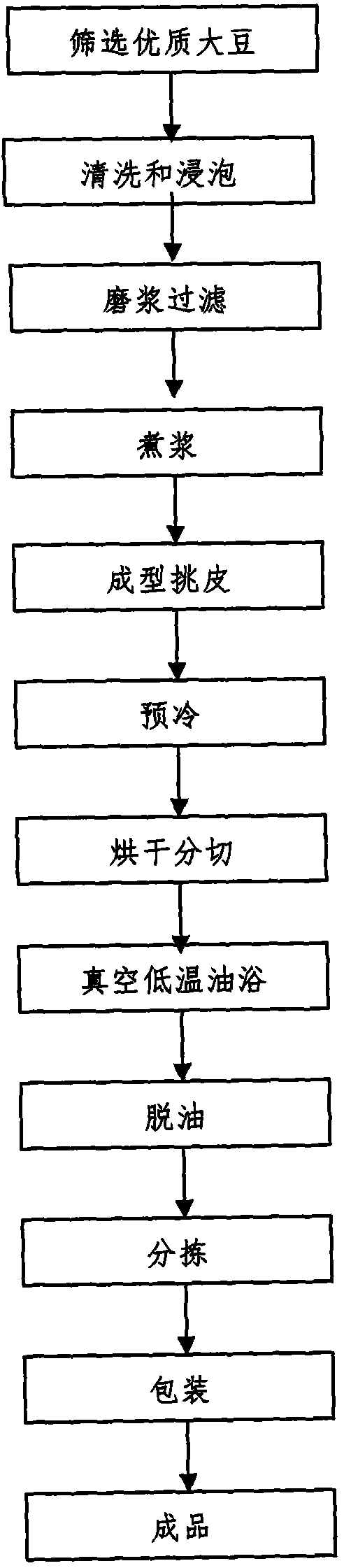

Image

Examples

Embodiment 1

[0031] 1) Material preparation: high-quality soybeans are selected as the main raw material, and the raw soybeans are preferably soybeans with a water content of 8%-10%, fat 18%-20%, and protein 38%-40%;

[0032] 2) Cleaning and soaking: After the soybeans are cleaned manually or mechanically, the soybeans are soaked in water at a ratio of 1:2.5. After soaking until the soybeans have only one-third of the hard core, they can be sent to the refining equipment for grinding. pulp;

[0033] 3) Refining and filtering: Use an electric refiner for refining, with a particle size of 2-3 mm and a sugar content of 7.2%-7.5%, and use a separator, vibrating screen or other filter screens of suitable specifications to filter the pulp. Filtration, such as filter cloth, nylon sieve, etc., to obtain soybean milk without coarse particles after filtering out impurities such as bean dregs, and reducing the particle size of solid particles in soybean milk is conducive to the full utilization of nu...

Embodiment 2

[0043] 1) Material preparation: high-quality soybeans are selected as the main raw material, and the raw soybeans are preferably soybeans with a water content of 8%-10%, fat 18%-20%, and protein 38%-40%;

[0044] 2) Cleaning and soaking: After the soybeans are cleaned manually or mechanically, the soybeans are soaked in water at a ratio of 1:2.5. After soaking until the soybeans have only one-third of the hard core, they can be sent to the refining equipment for grinding. pulp;

[0045] 3) Refining and filtering: use an electric refiner for refining, with a particle size of 2-3 mm and a sugar content of 7.2% to 7.5%, and use a separator, vibrating screen or other filter screens of suitable specifications to filter the pulp. Filtration, such as filter cloth, nylon sieve, etc., to obtain soybean milk without coarse particles after filtering out impurities such as bean dregs, and reducing the particle size of solid particles in soybean milk is conducive to the full utilization of...

Embodiment 3

[0055] Except for step 8) the conditions for vacuum low-temperature oil bath dehydration treatment are that the degree of vacuum is 0.09MPa, the temperature is 95°C, and the time is 25 minutes; after that, the built-in vacuum deoiling is carried out, and the deoiling time is 4 minutes, and other processes are the same as in Example 1. , Embodiment 2 makes all levels of products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com