PDMS-based bionic sharkskin replica super-hydrophobic surface and preparation method thereof

A technology of super-hydrophobic surface and shark skin, applied in the field of super-hydrophobic surface and its preparation, can solve the problems of high cost, poor mechanical stability, complicated preparation process, etc., and achieve the effects of low cost, controllable thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

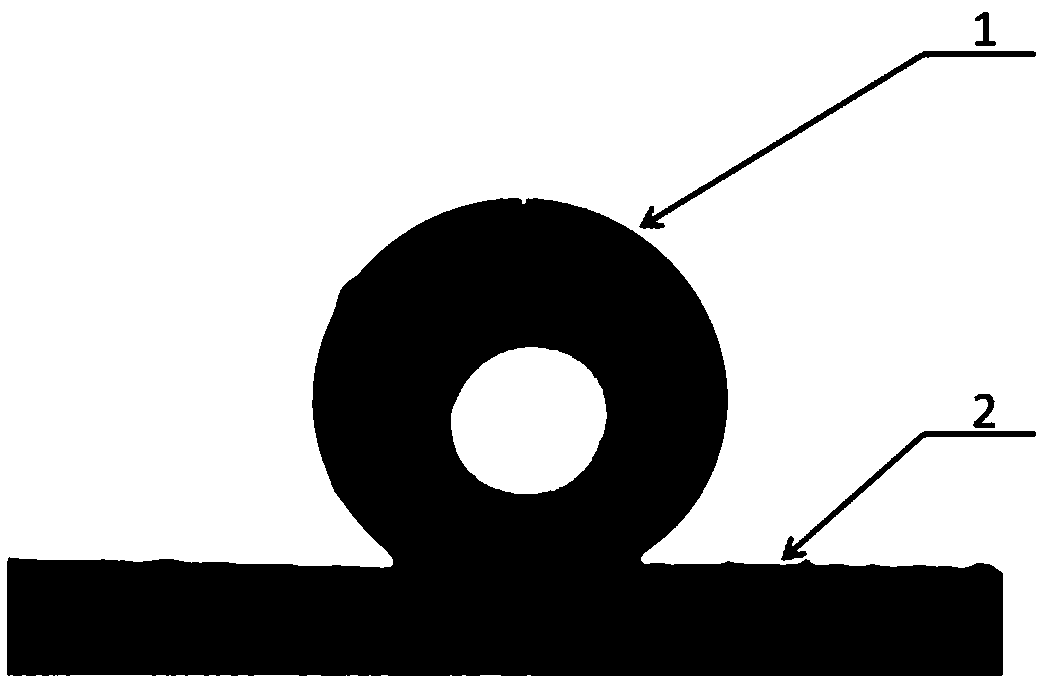

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with structural drawings and embodiments.

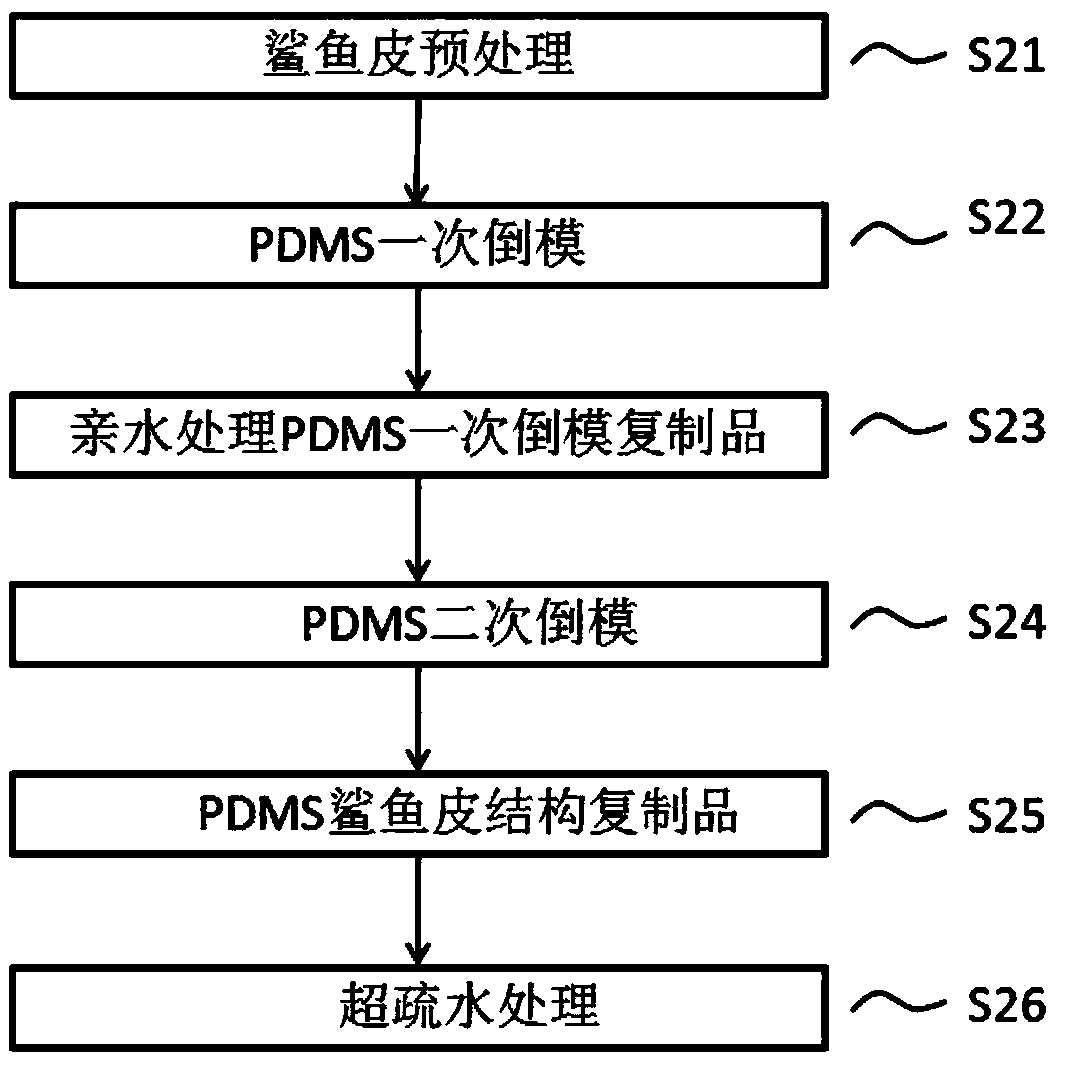

[0029] a) In order to ensure the accuracy of the shark skin replica, the shark skin must first be pretreated. When pre-treating the subcutaneous tissue of shark skin, two points must be ensured: one is to ensure that the thickness of the shark skin should be uniform, and the other is not to damage the microstructure of the shark skin surface.

[0030] b) After the shark skin subcutaneous tissue is processed, the shark skin should be ultrasonically cleaned and dried. During the drying process, the shark skin should be rigidly fixed to avoid deformation during the drying process. If there is any remaining unused shark skin, it should be soaked in formalin solution to prevent it from rotting and deteriorating.

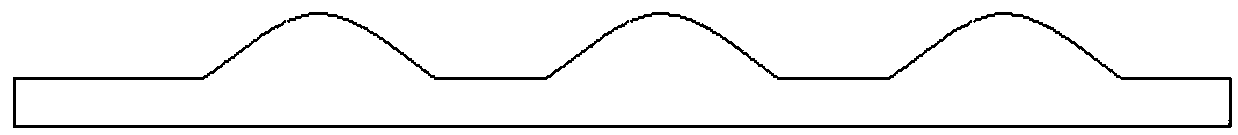

[0031] c) When copying the mold for the first time, use the pretreated sharkskin as a template for the first mold, and fix it with a baffle higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com