Gas-assistant extrusion molding device

A gas-assisted, extrusion molding technology, applied in the field of polymer extrusion molding, can solve problems affecting product accuracy, surface quality defects of extrudates, shark skin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

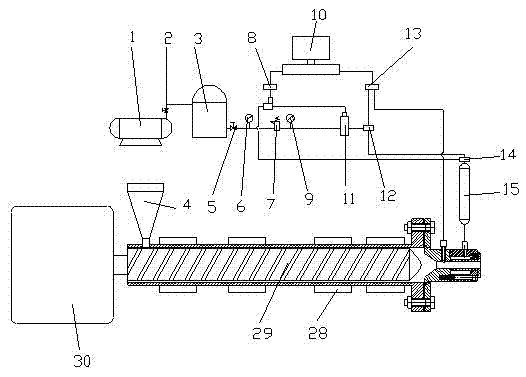

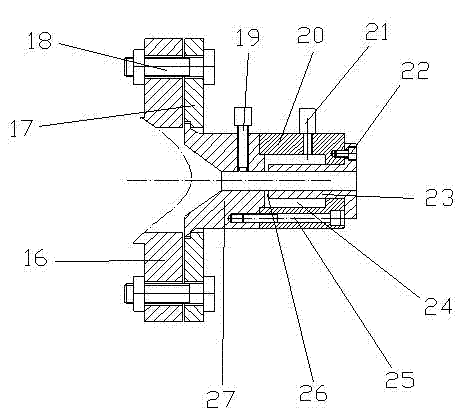

[0011] The device of the present invention includes three parts: extruder, gas control system and gas-assisted extrusion die; the extruder includes power part, feeding hopper, screw rod, heater; the gas control system includes air compressor, gas storage tank , valve, flow meter, electromagnetic proportional valve, D / A conversion card, pressure gauge, computer, pressure servo valve, pressure sensor, A / D conversion card, temperature controller, gas heater; gas-assisted extrusion die including the head Connecting plates, bolts, pressure plates, pressure and temperature sensors, die jackets, air inlets, screws, air-assisted extrusion sections and non-air-assisted extrusion sections;

[0012] The air compressor is connected to the inlet of the air storage tank through the valve, and the outlet of the air storage tank is connected to the valve, flow meter, electromagnetic proportional valve, pressure gauge, pressure sensor, temperature controller, gas heater and air inlet in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com