Method for lowering water conveying pipe head losses

A technology of water delivery pipeline and water head, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., which can solve the problems of large water flow resistance, small pipe diameter, energy loss, etc., and improve operating efficiency, The effect of reducing head loss and reducing frictional resistance of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

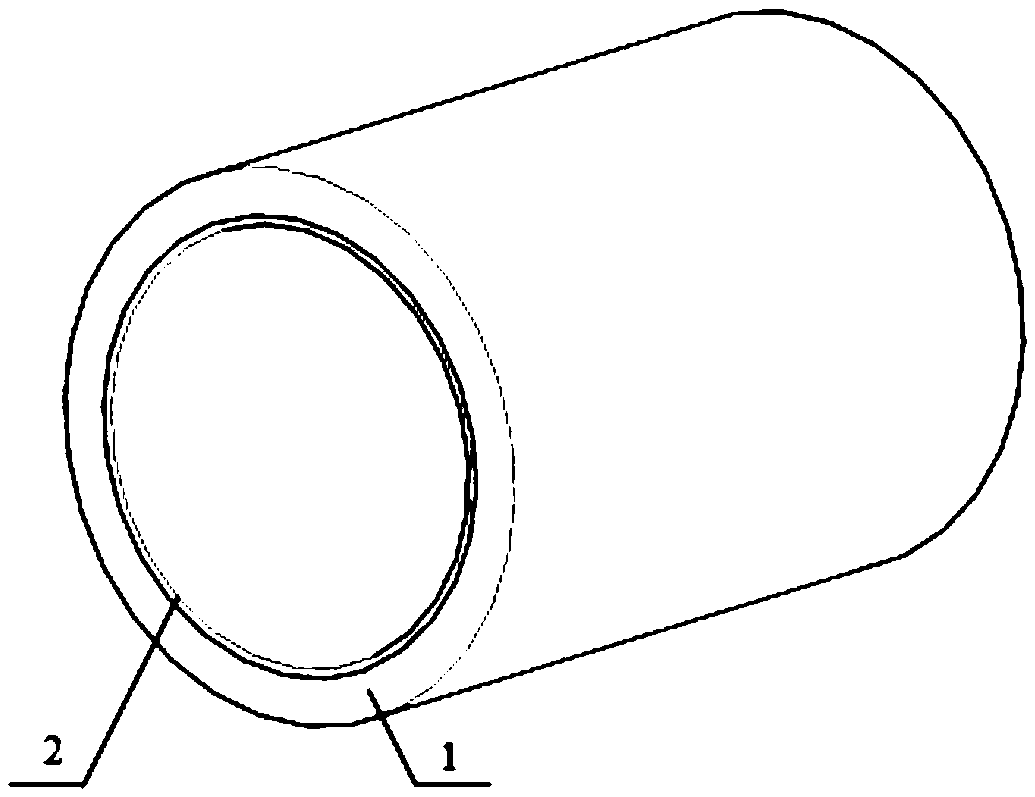

[0058] Such as figure 1 As shown, the imitation sharkskin material 2 is directly pasted on the inner wall of the water delivery pipe 1, and the imitation sharkskin material used is a silicone rubber molded PU imitation sharkskin. The specific process is as follows:

[0059] 1. Surface treatment: (1) The inner and outer walls of the pipe are sanded with sandpaper to wipe off the rust and retain a certain roughness; (2) Use 2% sodium hydroxide solution to clean; (3) Blow dry with cold wind, and the drying is completed waiting for painting;

[0060] 2. Paste imitation shark skin material:

[0061] (1) Apply the neutral silicone sealant evenly on the inner surface of the surface-treated water pipeline with a brush, and the coating thickness is 0.03mm.

[0062] (2) Dry for 30 minutes. During drying, care must be taken that the surface of the coating is absolutely free from contamination.

[0063] (3) Paste the silicone rubber molded PU imitation shark skin on the surface of the ...

Embodiment 2

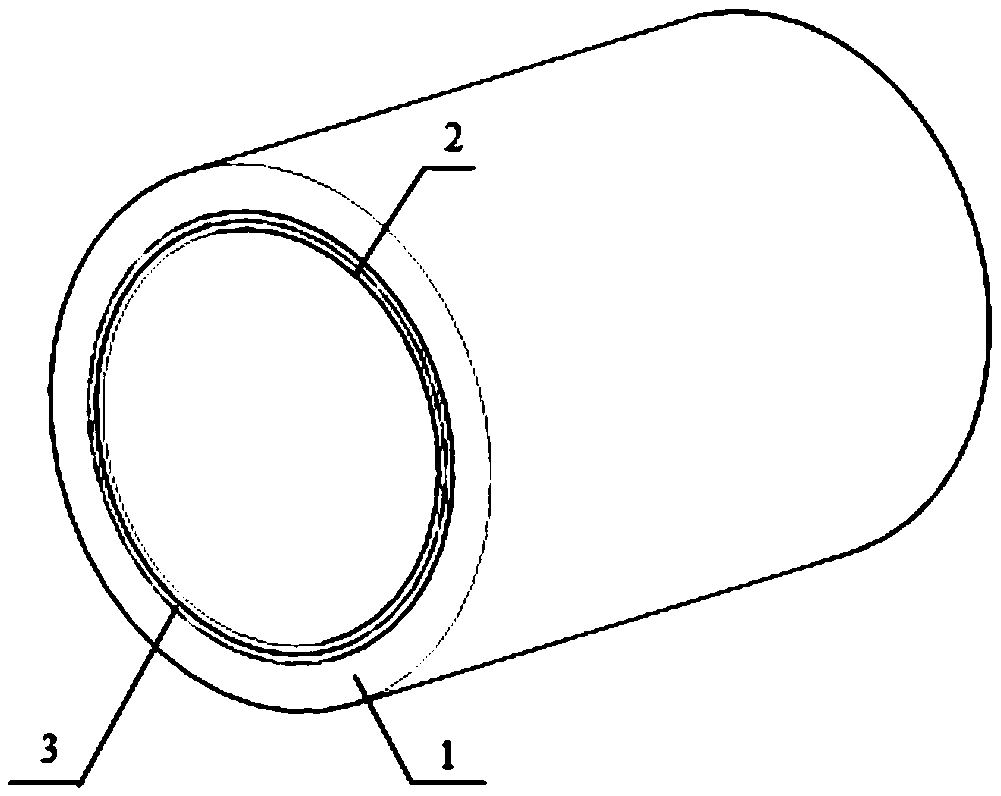

[0065] Such as figure 2 As shown, the base material 3 is first sprayed on the inner wall of the water pipeline 1, and then the imitation sharkskin material 2 is pasted. The imitation sharkskin material used is polyurethane-based imitation sharkskin. The specific process is as follows:

[0066] 1. Surface treatment, (1) sand the inner and outer walls of the pipe to wipe off the rust and retain a certain roughness; (2) use deionized water to clean; (3) dry it with cold wind, and wait for coating after drying. Pack;

[0067] 2. Spray base material: 3M94 primer adhesion promoter is atomized by a spray gun and attached to the inner surface of the water pipe; the thickness of the spray is 0.1mm, and it is dried at 60°C for 7 hours after spraying;

[0068] 3. Paste the imitation shark skin material:

[0069] (1) Apply the neutral silicone sealant evenly on the inner surface of the surface-treated water pipeline with a brush, and the coating thickness is 0.04mm.

[0070] (2) Dry f...

Embodiment 3

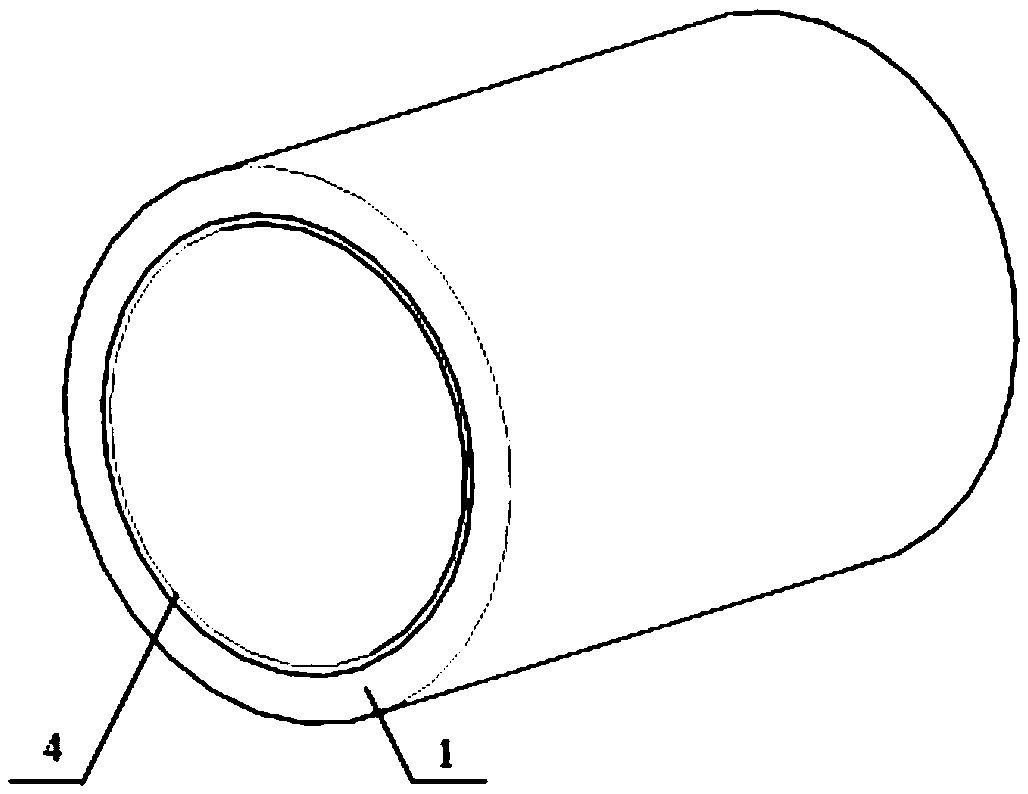

[0073] Such as image 3 As shown, the nano-superhydrophobic material 4 directly coats the inner wall of the water pipeline 1, and the nano-superhydrophobic material used is nano-organosilicon. The specific process is as follows:

[0074] 1. Surface treatment: (1) The inner and outer walls of the pipeline are polished with sandpaper to wipe off the rust and retain a certain roughness; (2) Use a mixed solution of 5% nitric acid and 5% hydrochloric acid to clean; (3) Use cold air Blow dry and wait for painting after drying;

[0075] 2. Spray nano-superhydrophobic material: atomize the nano-organosilicon material with a spray gun and attach it to the inner surface of the water pipe; after spraying, dry it at 60°C for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com