Heat preservation and decoration integrated facing tile and production method thereof

A technology of facing layer and insulation layer, which is applied in the direction of construction, building structure, covering/lining, etc., to achieve the effect of simple construction, meeting environmental protection requirements, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the thermal insulation and decoration integrated flexible facing brick of the present invention, the specific steps are as follows:

[0040] (1) Preparation of soft porcelain facing layer:

[0041] Weigh 20 parts of kaolin, 8 parts of 325 white Portland cement and 40 parts of 50 mesh quartz sand by weight, add them to the kneader, mix evenly, and obtain mixed powder; weigh the glass transition temperature by weight as - Add 10 parts of silicone-modified acrylate emulsion at 5°C, 5 parts of antimony trioxide, 1 part of titanium yellow and 15 parts of water into the stirring tank, and stir evenly to obtain a mixed emulsion; then add the mixed powder to the mixing Stir thoroughly in the emulsion to obtain a slurry; finally pour the slurry into a mold and dry in an oven at 40°C for 3 hours to obtain a soft porcelain veneer layer;

[0042] (2) Preparation of integrated flexible facing brick for thermal insulation and decoration:

[0043] Take by wei...

Embodiment 2-6

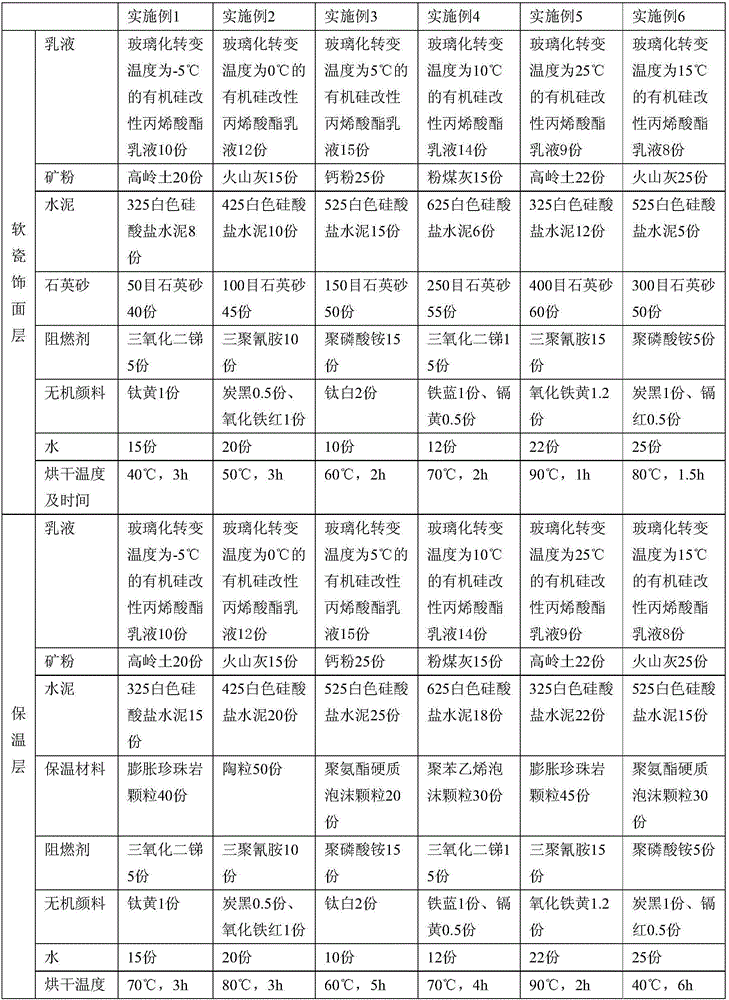

[0045] The raw material formula and the process parameters of preparation are shown in Table 1, and the specific preparation method is the same as in Example 1.

[0046] Table 1

[0047]

[0048]

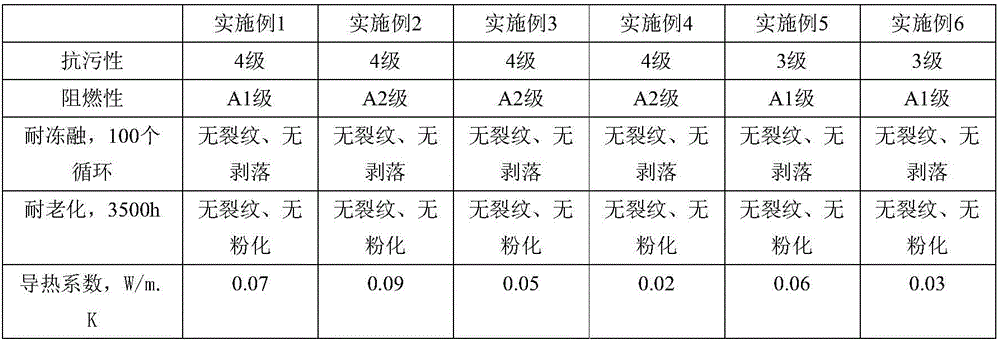

[0049] The samples obtained in the above examples were tested according to GB / T3810.13-2006 for stain resistance, GB / 8624-2006 for flame retardancy, GB / T3810.12-2006 for freeze-thaw resistance, and GB / T1865-1997 for aging resistance Sex and GB / T10294-2008 test thermal conductivity.

[0050] Table 2

[0051]

[0052] It can be seen from Table 2 that the thermal insulation and decoration integrated flexible facing brick prepared by the present invention has excellent stain resistance, freeze-thaw resistance, flame retardancy and aging resistance, and its thermal conductivity is lower than 0.1W / m.K, which meets the requirements of thermal insulation. Decorative material requirements. The thermal insulation and decoration integrated flexible facing brick prepared by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com