Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

A technology of microcrystalline foaming and manufacturing methods, which is applied in the field of construction engineering materials, can solve problems such as large deformation difference of plastering mortar, hollow bricks on external walls, and poor thermal insulation effect, so as to make up for poor thermal insulation performance and poor masonry construction. Simple, environmental stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

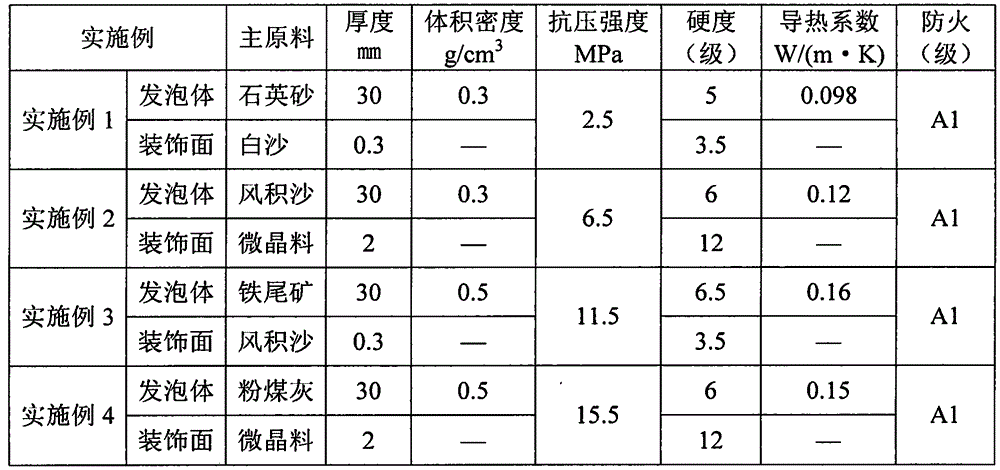

Embodiment 1

[0055] In terms of weight percentage, glass-ceramic frit made of quartz sand as the main raw material is 70%, potassium phosphate 2%, silicon carbide 2%, cullet 20%, dolomite 5%, limestone 1%, according to the above components and dosage For batching, put the obtained mixture into a ball mill to grind to obtain 350-mesh tailings microcrystalline composite fine powder, use a vibrating sieve to take 1-3mm white sand particles as decorative fabrics, and use an automatic distributing machine in the combined refractory mold Scatter and scrape the fine powder of tailing sand microcrystalline composite material and white sand in sequence respectively. According to the thickness ratio requirements, spread the fine powder of tailing sand microcrystalline composite material as foam material to 30% of the capacity of the combined mold, and use it as a decorative surface The white sand spread is 2% of the combined mold capacity, and the spreaded combined mold is sent to the roller kiln for...

Embodiment 2

[0057] In terms of weight percentage, 75% of glass-ceramic frit made of aeolian sand as the main raw material, 5% of boric acid, 10% of waste ceramics, 2% of glass powder, 3% of soda ash, and 5% of carbon black, according to the above components and The amount is used for batching, and the obtained mixture is ground in a ball mill to obtain a 400-mesh tailings microcrystalline composite fine powder. The glass-ceramic material made of aeolian sand as the main raw material is used as a decorative fabric. In the combined refractory mold, the tailing sand microcrystalline composite material fine powder and the glass ceramic material are spread and scraped in turn, and according to the thickness ratio requirements, the tailing sand microcrystalline composite material fine powder used as the foam material is spread to the capacity of the combined mold 30% of the combined mould, the white sand used as the decorative surface is spread to 5% of the capacity of the combined mold, and the...

Embodiment 3

[0059] In terms of weight percentage, 70% of glass-ceramic frit made of iron tailings as the main raw material, 1.5% of boric acid, 12% of cullet, 10% of glaze, 1.5% of silicon carbide, and 5% of gypsum, according to the above components and The amount is used for batching, and the obtained mixture is ground in a ball mill to obtain a 250-mesh tailings microcrystalline composite fine powder, and a crusher and a vibrating screen are used to prepare 80-mesh aeolian sand 40% and 60-mesh iron tailings respectively 60% of the glass-ceramic material made of the main raw material is used as a decorative fabric after mixing, and the fine powder of tailing sand and microcrystalline composite material and the decorative fabric are respectively spread and scraped in sequence in the combined refractory mold with an automatic distributing machine, according to the thickness ratio It is required that the fine powder of the tailing sand and microcrystalline composite material used as the foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com