Floating barrel duckbilled lotus root digging machine

A technology of lotus root digging machine and duckbill type, which is applied in the field of floating bucket duckbill type lotus root digging machine, can solve the problems of large detachment equipment, large equipment volume, difficulty in entering and leaving lotus root, etc. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

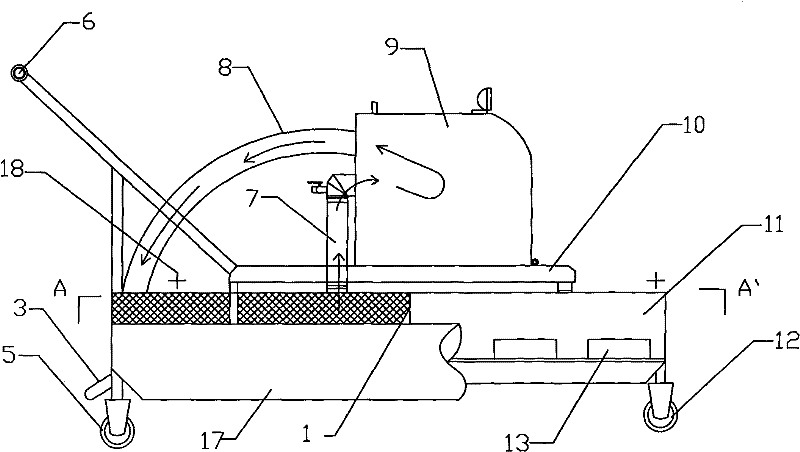

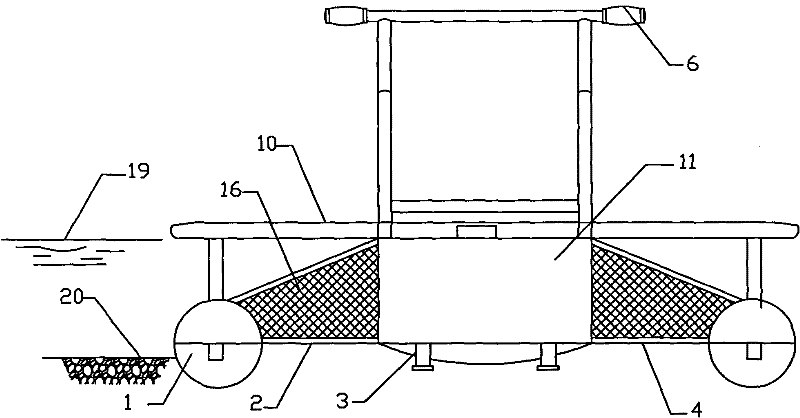

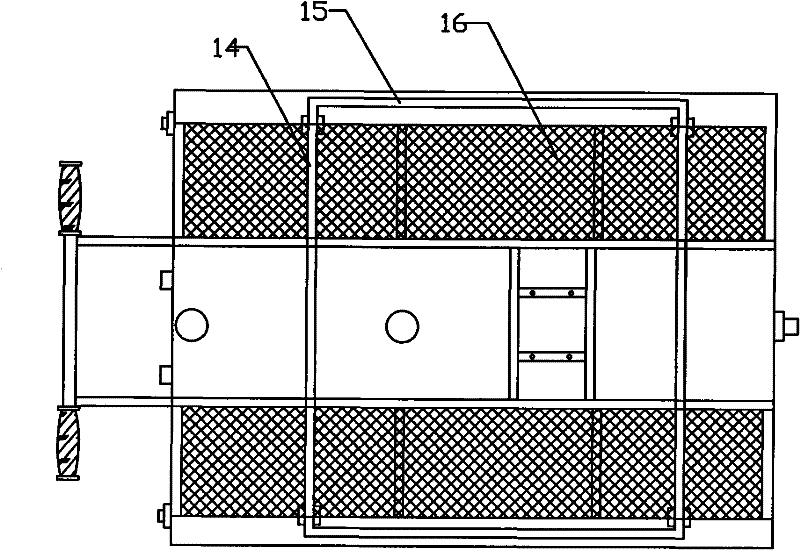

[0024] Below in conjunction with accompanying drawing, the present invention will be further described, figure 1 Among them, the floating bucket duckbill lotus root digging machine includes a chassis frame 14, a power pump chamber 9, a pump fixing frame 10, a water inlet pipe 7, a high-pressure pipe 8, a filter screen, and a high-pressure nozzle 3, and is characterized in that: The lotus root digging machine is equipped with left and right sealed floating barrels 1, and a working chamber 11 is arranged between the left and right sealed floating barrels 1, and the bottom, front, rear and top filter screens 2 are welded between the outer side of the working chamber 11 and the left and right sealed floating barrels 1 , 4, 16, the chassis frame 14 is welded as a whole with the left and right sealing buoys 1, the working chamber 11, the pump fixing frame 10, the operating frame 6, and the lifting bar 15.

[0025] The two sides of the working chamber 11 are provided with water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com